Reliable, consistent distance measurement up to 1 m

DT20 Hi distance sensor is the ideal choice for quality control tasks from a distance of up to 1 m. The reliable and precise distance measurement independent of any color, enables consistent check of any component. In addition, a precise red laser makes it possible to accurately detect very small objects. The DT20 Hi’s exceptional measurement performance and advanced settings are ideal for solving nearly any demanding measurement task.

DT20 Hi AT A GLANCE

Benefits

-Reliable, precise measurement, independent of surface, increases production quality

-Reliable and consistent measurements, regardless of color, reduce changeover time

-Advanced settings provide increased application flexibility to easily solve customer-specific applications

-Fast commissioning via button, remote or numerical teach

-Easy, precise alignment and verification based on red laser light and LC display, decreasing commissioning time

-Tough metal housing permits operation in harsh environments

Features

-Four measuring ranges from 50 mm up to 1,000 mm

-Very high linearity of up to ± 0.5 mm

-CMOS receiving element makes accurate distance measurement possible regardless of color and gloss

-Red light laser

-Freely scalable analog and digital output

-Display with intuitive menu navigation

-Extended adjustments (e.g. averaging, external laser-off function, etc.)

ADVANTAGES

.jpg) Precision meets quality

Precision meets quality

With expert-developed intelligent measurement technology which proves its worth in industrial applications time and time again, SICK offers the solution to any challenge which demands maximum measurement accuracy and quality. A pioneering spirit founded on our years of experience and our own innovations in optical sensor technology. We ensure efficient processes while fulfilling the demands of even complex measuring tasks – regardless of surface, diameter, thickness, or width, and regardless of whether an object is to be positioned or measured. This is how we ensure that your products are every bit as perfect as you want them to be. Moreover, SICK’s measurement technology supports quality assurance processes and delivers cost-saving benefits.

A point of light is projected onto the measuring object. The light reflected is captured by a light-sensitive receiver at a specific angle. Based on the angle between the send and receive direction, the position of the object is then triangulated (from the Latin “triangulum” = triangle).

.jpg)

The DT20 Hi displacement sensor provides reliable and precise measurement up to 1,000 mm in many applications, regardless of color and gloss. The sensor is suitable for detection, positioning, and process control applications in a wide variety of sectors, including the electronic and solar, pharma and metal industries, as well as machine building and robotics.

The DT20 Hi displacement sensor provides reliable and precise measurement up to 1,000 mm in many applications, regardless of color and gloss. The sensor is suitable for detection, positioning, and process control applications in a wide variety of sectors, including the electronic and solar, pharma and metal industries, as well as machine building and robotics.

Precise monitoring of unused film

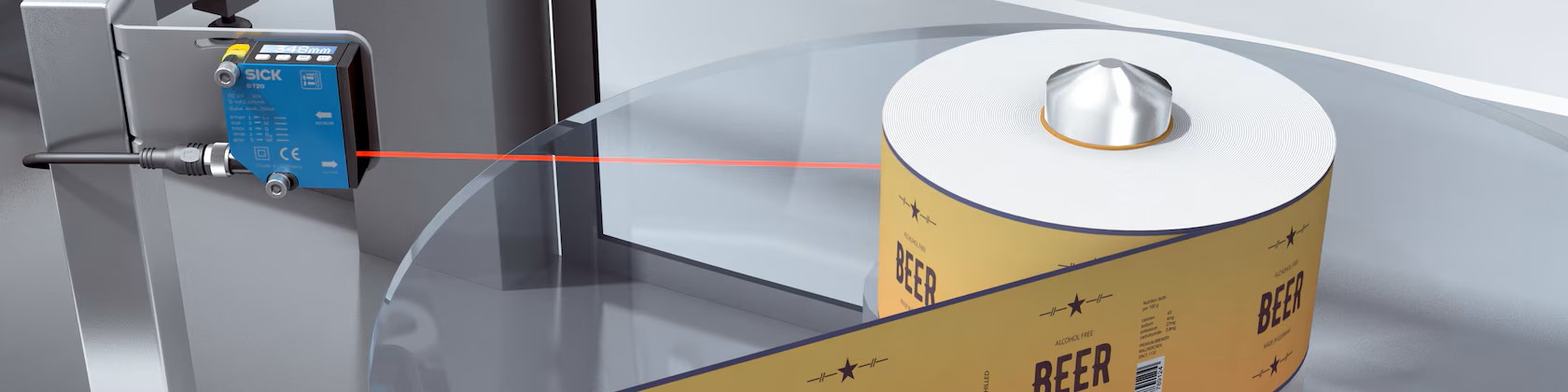

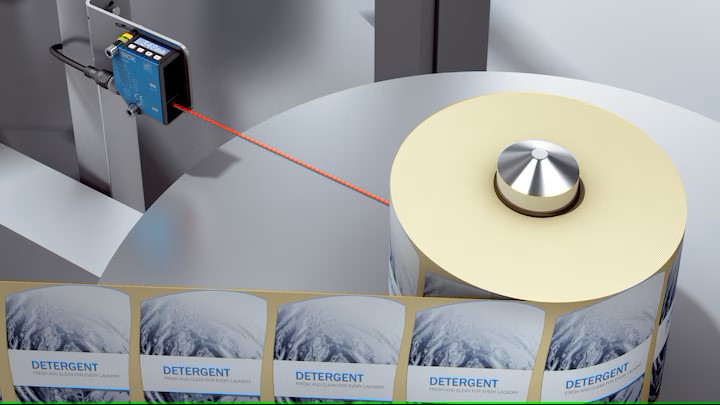

Powerful machines in the bottle filling sector apply up to 60,000 labels every hour non-stop. In order to use up as much of the thin label material as possible, the roll being used must be measured precisely. The high resolution of the DT20 Hi displacement measurement sensor minimizes unused labels and optimally controls the flying roll change via a switching output.

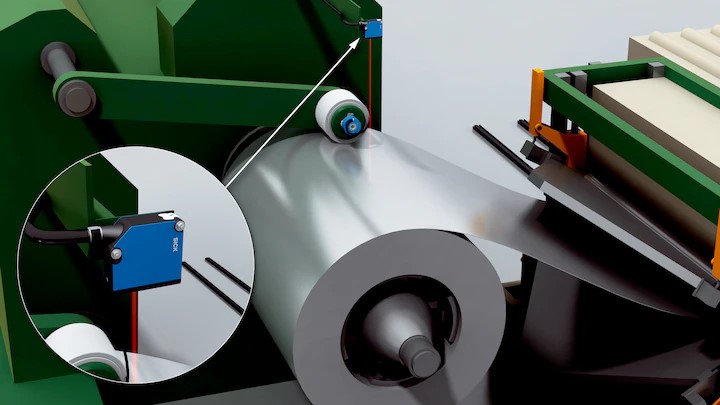

Sheet coil uncoiling

To ensure a constant feed of material, the uncoiling speed of the sheet coil must be regulated. The DT50 distance sensor measures the radius of the sheet coil continuously over the entire unwinding process. The DFS60 incremental encoder uses a friction roller to measure the retraction speed of the sheet. The measured values from both sensors are used to control the retraction speed and initiate automatic coil change.

The DT20 Hi is a rugged and economic single sensor solution which is easy to install and configure.