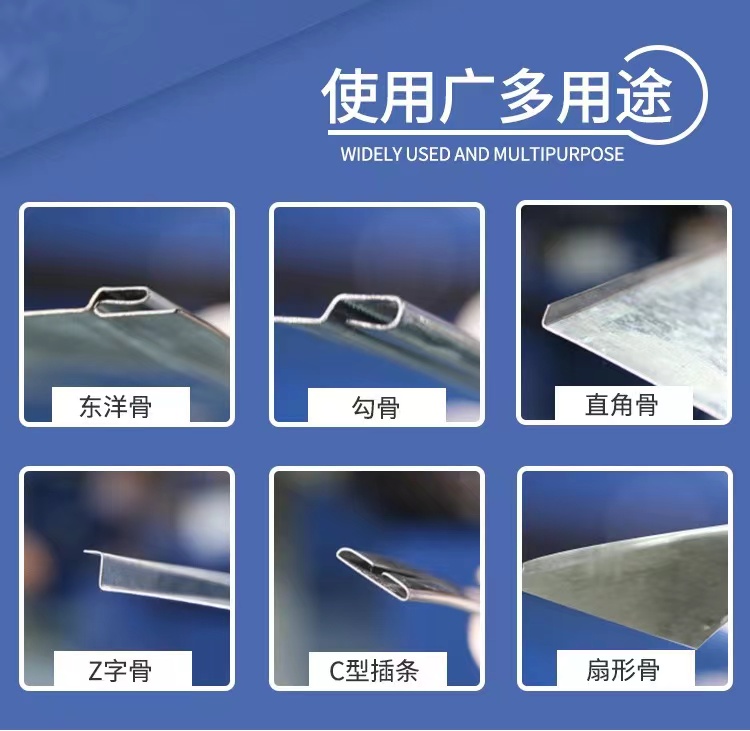

The seaming machine, also known as the air duct seaming machine, is a multifunctional bone-shaped seaming machine used for plate connection and air duct closed connection seaming processing. It can meet the needs of making different shapes of air duct bone shapes and can be formed. It combines seven functions: angle bite, hook bone, C-shaped insert, single flat mouth, right-angle bone (single bone), z-shaped bone (double bone), and elbow (bent angle). It is suitable for the production of air ducts for ventilation, air conditioning, purification, and other devices. According to requirements, it can be made into various sheet metal processing, air duct production, and other indispensable mechanized equipment.

Product Parameters:| Specification | Details |

|---|---|

| Model Specification | SA-12HB, SA-15HB |

| Processing Plate Thickness | 0.5-1.2mm, 0.5-1.5mm |

| Material | Galvanized Plate, White Iron Plate, Stainless Steel |

| Machine Weight | 550 kg |

| Dimensions | 1300*620*1100 mm |

| Motor Power | 1.5kw (for 1.2mm), 0.5-1.5mm |

| Customizable | Non-standard customization available |

| Warranty | One year warranty, lifetime maintenance |

| Motor | 3kw |

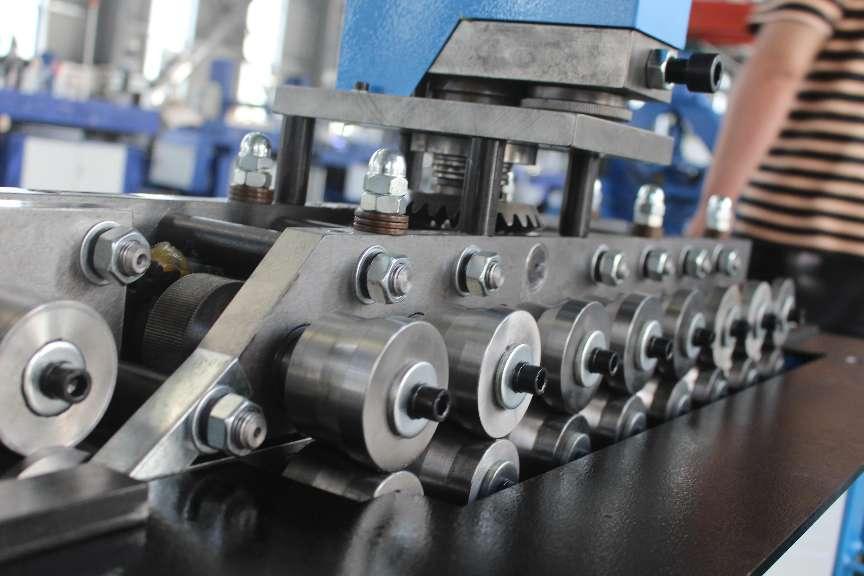

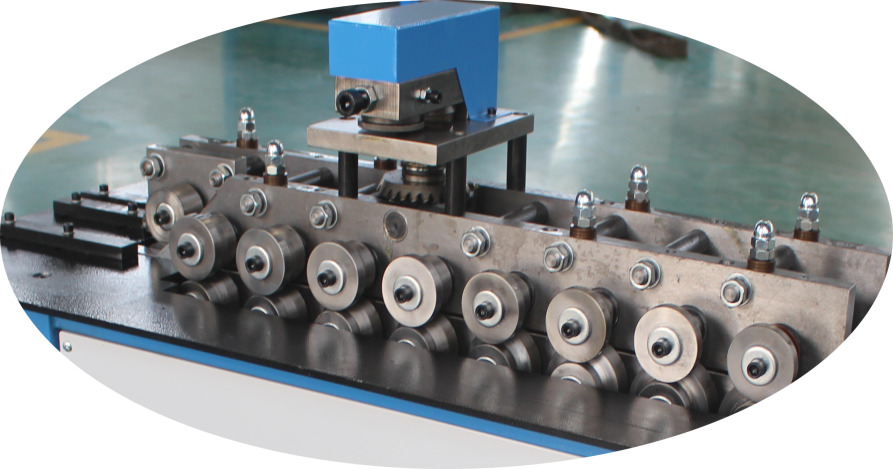

The material of the machine press wheel is bearing steel GCR15, which is completed by 9 sets of press wheels, making the runout small and the shape beautiful.

The bearings of the bite machine use pressure bearings to increase the speed, effectively avoiding side wear and extending the service life.

Feeding in and out depends on the ruler. The bite machine can process different bone shapes by adjusting the screws to change the position of the positioning plate.