As a pallet manufacturing and supplier, we understand the importance of reducing packaging costs without sacrificing performance. Through value engineering, we differentiate between unnecessary and necessary costs while maintaining the packaging’s quality and functionality. With our unwavering commitment to excellence, we are confident in our ability to provide the best packaging solutions for our customers.

Our objective is simple but significant: to exceed customer expectations. Our mission aims to achieve this by providing total packaging solutions with quality and saving pallet that are tailored to meet our customer’s needs, especially in the heavy-duty segment. Our unwavering mission is to be the best in the industry.

Our management policies prioritize customer satisfaction, and we maintain the highest quality standards at every level of our organization.

Our highly skilled and dedicated staff members are committed to delivering top-quality work, from important and complex processes to even the smallest tasks. We ensure that “quality” is inherent in every process, and We always maintain excellent housekeeping.

At our company, we are driven by a deep passion for pallet manufacturing, Our passion for pallet manufacturing is at the heart of everything we do, and our values reflect our unwavering commitment to our customers and our desire to create the best products possible.

At the core of our values is a commitment to accountability, which we believe is essential to our success. We take responsibility for our actions and our work, and we are committed to delivering high-quality results that meet our customers’ needs.

Through our dedication to these values, we are confident in our ability to provide outstanding pallet solutions that meet the highest standards of quality and excellence.

Mixed Tropical Hardwood Pallets/ Cases / Crates |

|---|

|

|

|

|

|

|

|

|

|

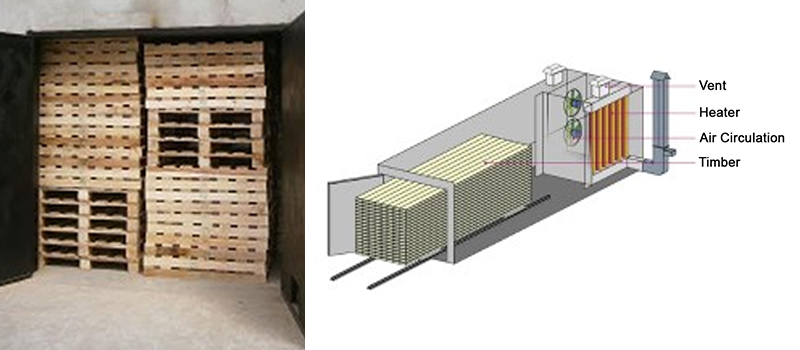

We are guided by a set of stringent quality control policy. Our Pallet products are manufactured & tested of a quality insurance, ISO9001: 2008 accreditation. We also conversant with ISPM15 regulations governing the export of packaging products.

Mixed wooden pallets are still the most commonly used pallet in most industries as it is more cost-effective while providing the strength and durability that are expected.

Wooden pallets are not expensive and have proven to withstand rough handling in many logistics and transportation modes. The advantage of wooden pallets is that they can be used multiple times over the course of their lifetime. However, wooden pallets also need proper maintenance and repair in order to achieve full cost-saving potential. Worn-out or broken pallets can be repaired for reuse. As such, the end-of-life pallets can be recycled. In this way, the industries can help the nation’s aspiration in achieving the 3R concept of Reduce, Reuse & Recycle where we can help to reduce carbon footprints. Besides providing solutions to the material handling sector, wooden pallets can also be used in many other innovative DIY projects as well as for furniture making.

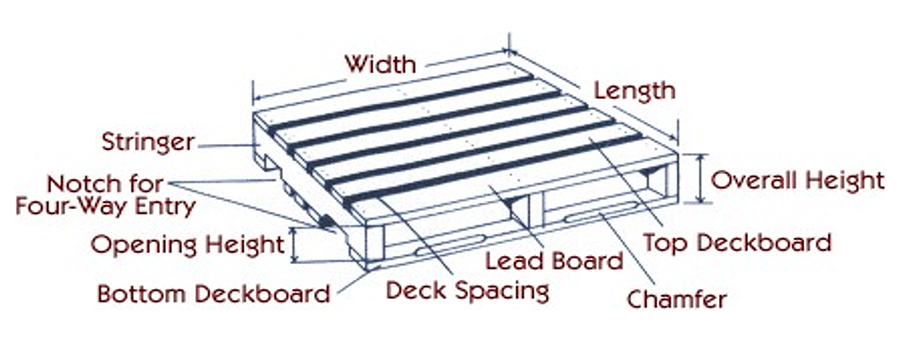

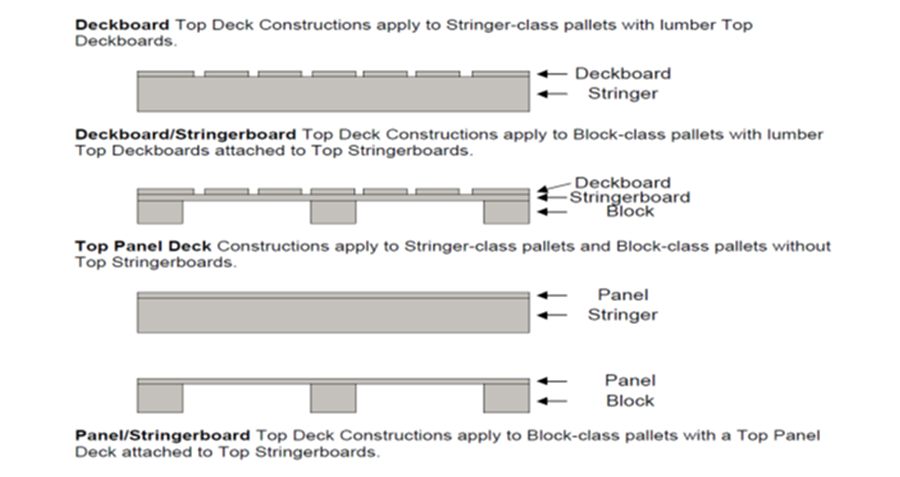

Pallets utilize rectangular stringers (or runners) – wood components that run the full length of the pallet. The top deck is fastened to the top edge of the stringers. For double-face pallets, the bottom deck is fastened to the bottom edge of the stringers..

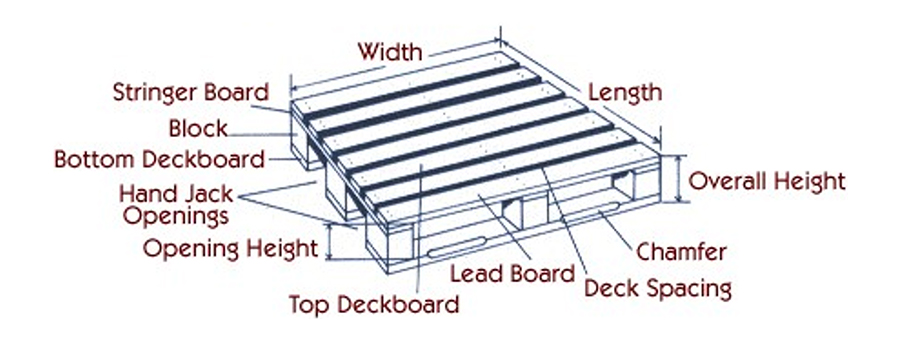

Pallets utilize rectangular blocks (or cylindrical posts), which separate the top deck from bottom deck(if Double-Face). Block pallets with lumber decks have top stringer boards, which run the full length of the pallet and are fastened to the blocks.

Wooden pallets are very cost effective and are probably a good choice in most cases. you should look at alternatives when you are looking for a specific property like low weight or cleanliness.

Malaysia

Malaysia