Portable Wire Rope Inspection

We developed on basis of magnetic inductive sensing technology and MFL(magnetic flux leakage) wire rope inspection technique. The system can be applied for the portable inspection of steel wire ropes and steel pipes for the physical damages or material deteriorations.

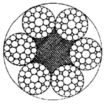

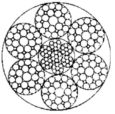

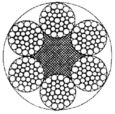

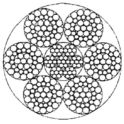

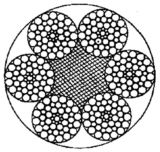

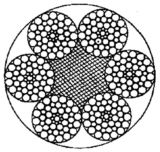

TS-X1124\X1142\X1160(X) are the 3 standard models in the portable series for the inspection of steel wire ropes with diameters of 6mm-70mm.

Customized models can be developed based on specific applications of the clients, such as for extra wide wire ropes up to 120mm, and for enviroments that require Intrinsic Safe and Explosion Proof design.

General

General

•Nondestructive inspection of wire rope with diameter from

6-70mm

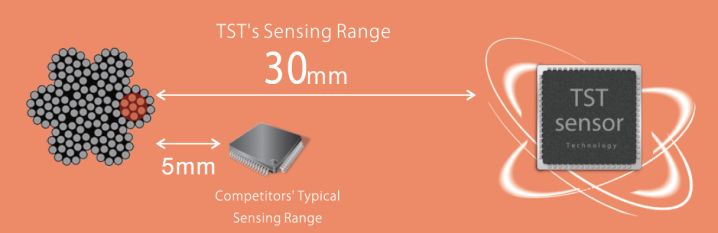

•Detection powered by TST sensor array

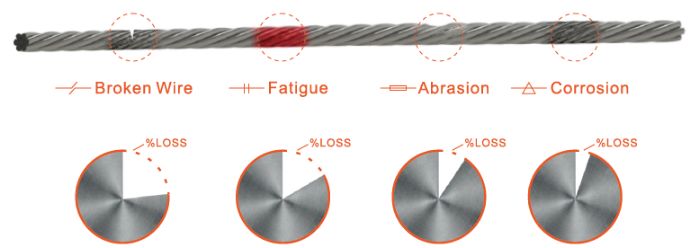

•Portable detection of various flaw types including broken wire, corrosion , pitting, abrasion , fatigue etc for which a magnetic signature will be left due to the occurrence of a flaw event

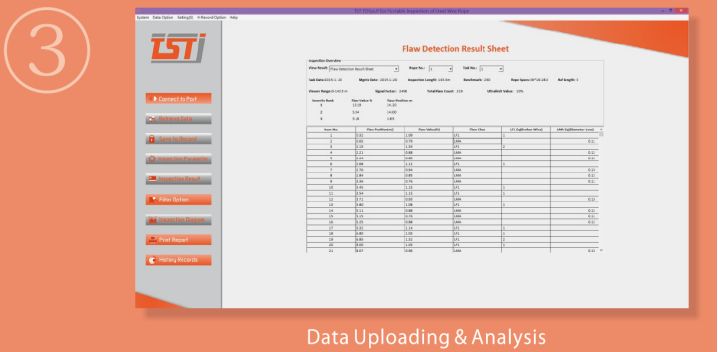

•Instant monitoring and evaluation of inspection process with portable 'Control Panel' and 'Screen'

•Data processing with built-in signal processor for portable application

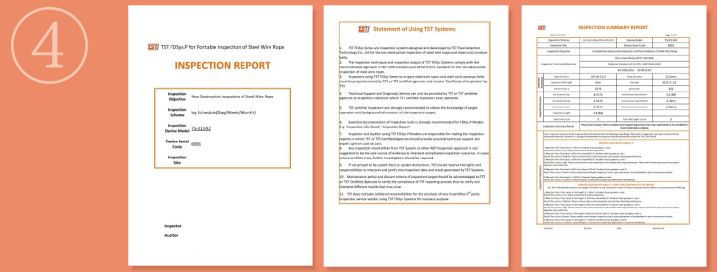

•Evaluating and reporting with built-in and PC software set for portable application

Inspection Speed

Inspection Speed

•< 15 mis (or as limited for safe operation)

•< 15 mis (or as limited for safe operation)

Defect Types

•LF(Local Fault) LMA(Loss of Met allic Area)

•Physical damages:Broken wire,Abrasion,

Structure Deformation

•Material Deteriorations: Corrosion, Fatigue

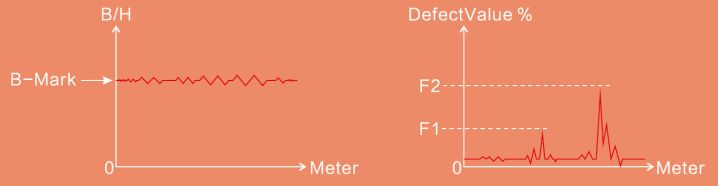

Flaw Detection

• Qualitative Flaw Detection

• Quantitative Flaw Detection

• High Repeatibility

• High Accuracy

• Waveform Insp ect ion Diagram Output

• Statistical Insp ection Result Table Output

Features

Features

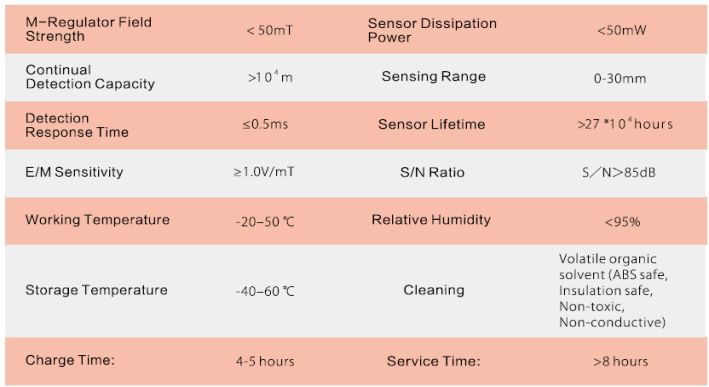

Specifications

Specifications

| MODEL | ROPE DIAMETER |

ROPE SAMPLE REMARK |

| TS X1124 | Ø6-24mm |     6x7+FC Ø8 6x9W+IWR Ø15 6x19S+FC Ø20 6x19W+IWR Ø24 |

| TS X1142 | Ø22-42mm |     6x26WS+IWR Ø25 6X31WS+IWR Ø30 6X29Fi+FC Ø35 6x29Fi+IWR Ø40 |

| TS X1160 | Ø40-65mm |   6x36WS+FC Ø45 6x37S+IWR Ø50   6X49SWS+FC Ø55 6X55SWS+IWR Ø60 |

| TS X1160X | Ø40-70mm |

Performance

Performance

Field application

Field application