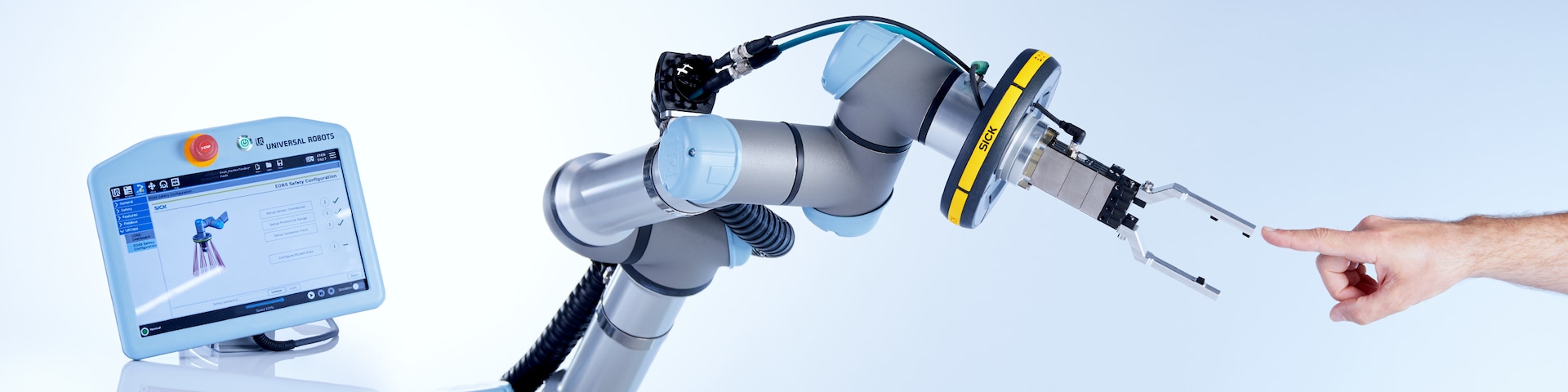

End-of-Arm-Safeguard is an innovative safety system for collaborative robot applications. The system creates a protective field around the robot tool, reduces the risk of crushing injuries, and makes it possible to work safely in the immediate vicinity of the robot. Thanks to contactless technology, the robot stops before a collision occurs. This increases the confidence of operators and increases productivity. With its small protective field, End-of-Arm-Safeguard offers a protection solution exactly where it is needed, thereby creating more space for humans and machines. The system is designed for the e-Series from Universal Robots. It is installed directly on the robot flange. Configuration is carried out via the UR Teach Pendant.

Benefits:

Worker acceptance and trust in the robot: End-of-Arm-Safeguard stops the robot movement before crushing occurs

Features:

Adequate safety solution

To safeguard against the residual risk of crushing by the gripper and workpiece, the End-of-Arm-Safeguard with Performance Level c offers an adequate level of safety for many collaborative robot applications.

The End-of-Arm-Safeguard is installed directly on the robot flange and is fully integrated into the robot safety system of Universal Robots via the EOAS-URCap. Configuration is intuitive and quick via the UR Teach Pendant, which means the entire installation process usually only takes 15 minutes. No expert knowledge is required for productive, daily operation.

The safety system hardware is mounted directly on the robot flange in next to no time and connected to the robot controller with two connection cables.

The URCap of the End-of-Arm-Safeguard is designed as a safety plug-in. It is installed and activated directly via the UR Teach Pendant on the robot controller.

Safety configuration in just three steps: Set IP address, define protective field length, teach-in validation point. You can then start the robot program.

The protective field of the End-of-Arm-Safeguard moves with the robot arm and is always there where it is needed. This optimizes the use of space in the workshop, avoids unnecessary robot stops during operation, and gives the operating personnel the freedom of movement they need to work efficiently and ergonomically.

Large protective fields and fences around the application significantly restrict the movement radius and (machine) access of the operating personnel. With the End-of-Arm-Safeguard, the working environment can be made freer and more attractive.

Malaysia

Malaysia