EVP - Steam Ejector System

Description: EVP steam ejector and air ejector with water-saving, steam conservation features, it’s widely used in edible oil,waste oil refining,fatty acid distillation, deodorization.

Product Info:

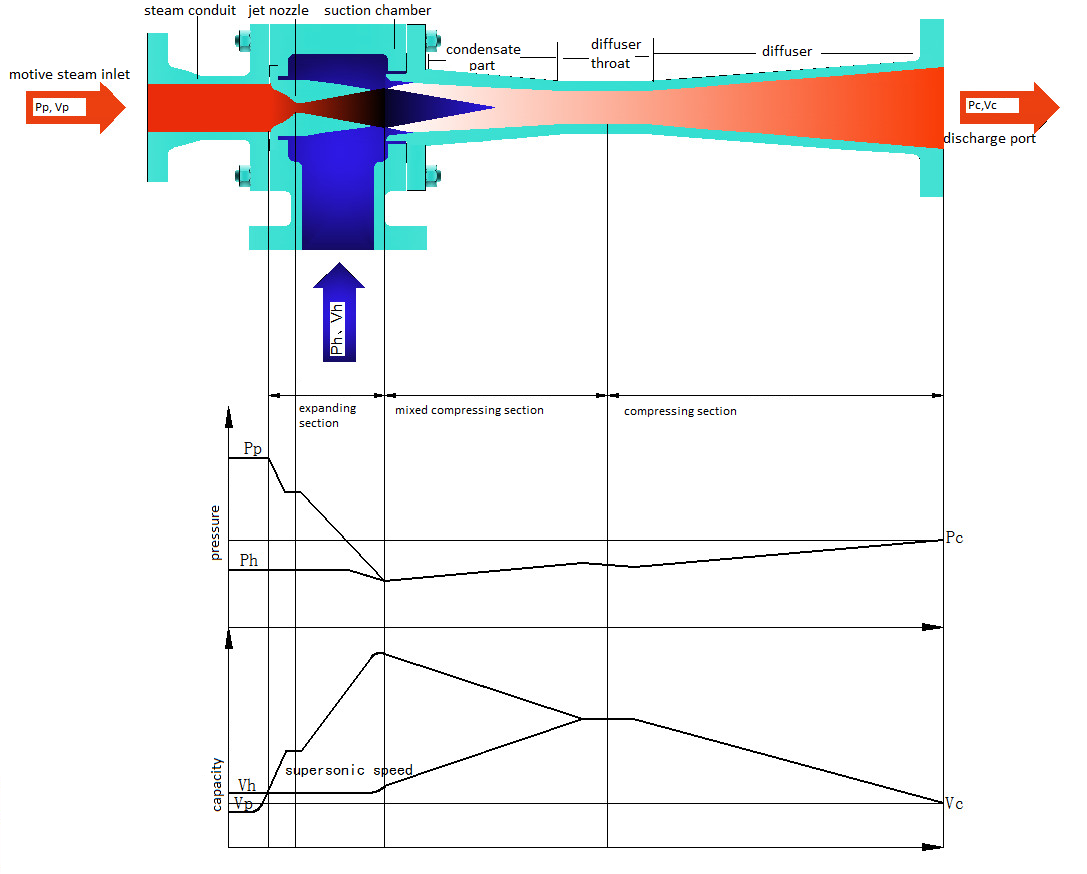

Steam ejector is type of vacuum obtain device with certain pressure. Motive steam passing through the jet nozzle,its pressure decreased and speed accelerated, the steam’s potential energy is turned into kinetic energy, ejected into suction (mixing) chamber and mixed with evacuated gas. Then the energy is exchanged. When mixed air entering the diffuser, its speed lowered and pressure increased, the kinetic energy is turned into pressure energy. Followed can be found the general working principle:

besides, it’s also good option to be worked together with liquid ring vacuum pump to create higher ultimate pressure.

The combination of ejector and condenser meets various needs of vacuum

Main Features:

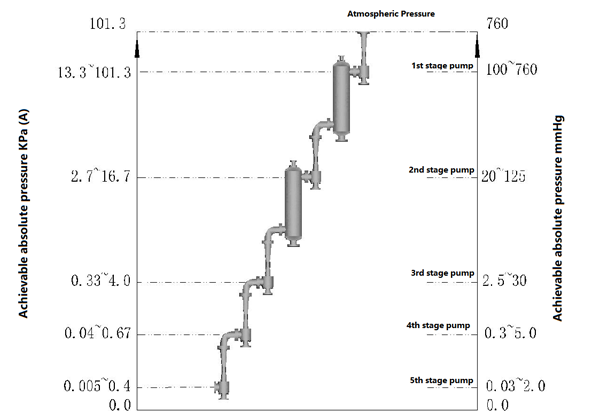

The working vacuum range is very wide: 0.005-101.3KPa (A);

The pumping volume can theoretically be unlimited;

There are no strict restrictions on the pumping medium, no matter the humidity of the pumped medium is high or low, whether there is dust or corrosion, it can be used;

No rotating parts, long service life;

Safe and reliable work, simple operation, low cost and easy maintenance;

With an intermediate condenser, a 12m high position is required;

Simple structure; reliable technology;stable vacuum degree; low maintenance and long service life.

It can be used to suction some corrosive gas, flammable, explosive gas and particulate medium,etc. directly.

Multi-stage steam ejector vacuum system with leading technology, stable performance and the lowest operating cost features. The other products are incomparable.

Steam jet vacuum pump features and applications:

vacuum metallurgy, vacuum deaeration, vacuum impregnation, freeze drying, concentration, distillation, refrigeration,vacuum evaporation of petroleum, chemical, pharmaceutical, oil, sugar, salt, paper and other fields,such as concentration, drying, distillation, distillation, crystallization, dehydrated, filtering, vacuum conveying material, chemical absorption and degassing process. With different pumping speed and working vacuum, we have many types of model for customer selection.

Specifications:

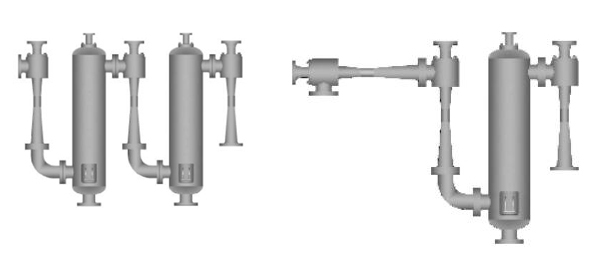

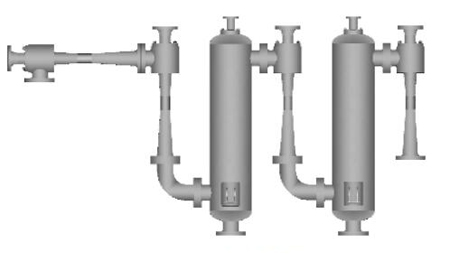

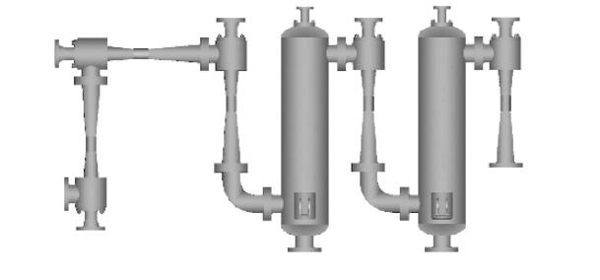

Steam jet vacuum pump layout :

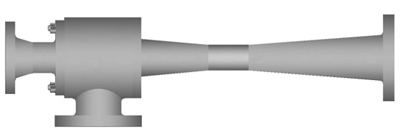

Single stage steam jet vacuum pump

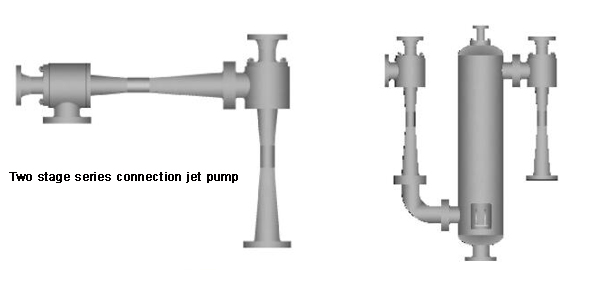

Two stage steam jet vacuum pump

| model | Vacuum absolute pressure |

Pumping volume

Air + water vapor kg/h |

Working steam pressure

MPa |

Working steam consumption

kg/h |

Cooling water temperature

OC |

Cooling water circulation

m3/h |

|

|

Working vacuum

mmhg/KPa |

Ultimate vacuum

mmhg/Pa |

||||||

| ⅡZPL(5/10)-40 | 40/5.3 | 16/2 | 5+10 | 0.5 | 68 | 32 | 3 |

| ⅡZPL(5/18)-40 | 40/5.3 | 16/2 | 5+18 | 0.5 | 110 | 32 | 4 |

| ⅡZPL(10/25)-40 | 40/5.3 | 16/2 | 10+25 | 0.5 | 188 | 32 | 6 |

| ⅡZPL(10/35)-40 | 40/5.3 | 16/2 | 10+35 | 0.5 | 198 | 32 | 7.5 |

| ⅡZPL(15/50)-40 | 40/5.3 | 16/2 | 15+50 | 0.5 | 273 | 32 | 11 |

| ⅡZPL(15/80)-40 | 40/5.3 | 16/2 | 15+80 | 0.5 | 420 | 32 | 16 |

| ⅡZPL(25/45)-75 | 75 | 30/4 | 25+45 | 0.8 | 135 | 32 | 6.8 |

| ⅡZPL(35/55)-75 | 75 | 30/4 | 35+55 | 0.8 | 238 | 32 | 7 |

Three stage steam jet vacuum pump

| model | Vacuum absolute pressure |

Pumping volume

Air + water vapor kg/h |

Working steam pressure

MPa |

Working steam consumption

kg/h |

Cooling water temperature

OC |

Cooling water circulation

m3/h |

|

|

Working vacuum

mmhg/KPa |

Ultimate vacuum

mmhg/Pa |

||||||

| ⅢZPL(8/20)-20 | 20/2.6 | 8/1 | 8+20 | 0.5 | 80 | 32 | 5 |

| ⅢZPL(8/30)-20 | 20/2.6 | 8/1 | 8+30 | 0.5 | 130 | 32 | 8 |

| ⅢZPL(10/40)-20 | 20/2.6 | 8/1 | 10+40 | 0.5 | 155 | 32 | 10 |

| ⅢZPL(10/50)-20 | 20/2.6 | 8/1 | 10+50 | 0.5 | 234 | 32 | 15 |

| ⅢZPL(10/60)-20 | 20/2.6 | 8/1 | 10+60 | 0.5 | 256 | 32 | 18 |

| ⅢZPL(10/80)-20 | 20/2.6 | 8/1 | 10+80 | 0.5 | 289 | 32 | 20 |

| ⅢZPL(10/100)-20 | 20/2.6 | 8/1 | 10+100 | 0.5 | 335 | 32 | 35 |

| ⅢZPL(20/150)-20 | 20/2.6 | 8/1 | 20+150 | 0.5 | 387 | 32 | 35 |

| ⅢZPL(20/200)-20 | 20/2.6 | 8/1 | 20+200 | 0.5 | 456 | 32 | 40 |

| ⅢZPL(30/250)-20 | 20/2.6 | 8/1 | 30+250 | 0.5 | 491 | 32 | 45 |

| ⅢZPL(30/300)-20 | 20/2.6 | 8/1 | 30+300 | 0.5 | 532 | 32 | 48 |

| ⅢZPL(30/350)-20 | 20/2.6 | 8/1 | 30+350 | 0.5 | 732 | 32 | 50 |

| ⅢZPL(40/400)-20 | 20/2.6 | 8/1 | 40+400 | 0.5 | 789 | 32 | 55 |

| ⅢZPL(40/450)-20 | 20/2.6 | 8/1 | 40+450 | 0.5 | 888 | 32 | 60 |

Four stage steam jet vacuum pump

| model | Vacuum absolute pressure |

Pumping volume

Air + water vapor kg/h |

Working steam pressure

MPa |

Working steam consumption

kg/h |

Cooling water temperature

OC |

Cooling water circulation

m3/h |

|

|

Working vacuum

mmhg/KPa |

Ultimate vacuum

mmhg/Pa |

||||||

| ⅣZPL(8/20)-1 | 1/133 | 0.2/27 | 8+20 | 0.5 | 362 | 32 | 50 |

| ⅣZPL(8/30)-1 | 1/133 | 0.2/27 | 8+30 | 0.5 | 430 | 32 | 50 |

| ⅣZPL(10/40)-1 | 1/133 | 0.2/27 | 10+40 | 0.5 | 680 | 32 | 70 |

| ⅣZPL(10/60)-1 | 1/133 | 0.2/27 | 10+60 | 0.5 | 980 | 32 | 100 |

| ⅣZPL(10/80)-1 | 1/133 | 0.2/27 | 10+80 | 0.5 | 1230 | 32 | 160 |

| ⅣZPL(10/100)-1 | 1/133 | 0.2/27 | 10+100 | 0.5 | 1500 | 32 | 180 |

| ⅣZPL(20/120)-1 | 1/133 | 0.2/27 | 20+120 | 0.5 | 1980 | 32 | 200 |

| ⅣZPL(20/150)-1 | 1/133 | 0.2/27 | 20+150 | 0.5 | 2500 | 32 | 200 |

| ⅣZPL(20/200)-1 | 1/133 | 0.2/27 | 20+200 | 0.5 | 3000 | 32 | 250 |

| ⅣZPL(30/300)-1 | 1/133 | 0.2/27 | 30+300 | 0.5 | 4500 | 32 | 300 |

| ⅣZPL(40/400)-1 | 1/133 | 0.2/27 | 40+400 | 0.5 | 6000 | 32 | 380 |

| ⅣZPL(50/500)-1 | 1/133 | 0.2/27 | 50+500 | 0.5 | 7000 | 32 | 550 |

| ⅣZPL(80/800)-1 | 1/133 | 0.2/27 | 80+800 | 0.5 | 10000 | 32 | 650 |

| ⅣZPL(8/20)-2 | 2/267 | 0.3/40 | 8+20 | 0.5 | 256 | 32 | 50 |

| ⅣZPL(8/30)-2 | 2/267 | 0.3/40 | 8+30 | 0.5 | 295 | 32 | 50 |

| ⅣZPL(10/40)-2 | 2/267 | 0.3/40 | 10+40 | 0.5 | 490 | 32 | 60 |

| ⅣZPL(10/60)-2 | 2/267 | 0.3/40 | 10+60 | 0.5 | 680 | 32 | 70 |

| ⅣZPL(10/80)-2 | 2/267 | 0.3/40 | 10+80 | 0.5 | 930 | 32 | 100 |

| ⅣZPL(10/100)-2 | 2/267 | 0.3/40 | 10+100 | 0.5 | 1000 | 32 | 120 |

| ⅣZPL(20/120)-2 | 2/267 | 0.3/40 | 20+120 | 0.5 | 1100 | 32 | 150 |

| ⅣZPL(20/150)-2 | 2/267 | 0.3/40 | 20+150 | 0.5 | 1234 | 32 | 180 |

| ⅣZPL(20/200)-2 | 2/267 | 0.3/40 | 20+200 | 0.5 | 1600 | 32 | 200 |

| ⅣZPL(30/300)-2 | 2/267 | 0.3/40 | 30+300 | 0.5 | 2332 | 32 | 250 |

| ⅣZPL(40/400)-2 | 2/267 | 0.3/40 | 40+400 | 0.5 | 2567 | 32 | 300 |

| ⅣZPL(50/500)-2 | 2/267 | 0.3/40 | 50+500 | 0.5 | 3200 | 32 | 350 |

| ⅣZPL(80/800)-2 | 2/267 | 0.3/40 | 80+800 | 0.5 | 3819 | 32 | 400 |

Five stage steam jet vacuum pump

Note:

1. The models listed in the table are not exhaustive, and can be designed according to the technical parameters provided by users.

2. The technical parameters change accordingly when the user’s process conditions change, so the technical parameters are subject to the technical parameters given at the time of signing the contract.

Lihat detail lebih lanjut tentang Hexo Industries (M) Sdn Bhd

Malaysia

Malaysia