Position sensors with very good price-performance ratio for T-slot

The cost-effective MPS-M position sensor detects the piston position in pneumatic drives continuously and with micrometer precision without making contact. It is designed for cylinders with T-slots and can be mounted quickly, easily and securely. After installation, the MPS-M can be used directly for measurements – there is no need for parameterization or teach-in when recording the piston position. It continuously delivers exact position data via analog interface or IO-Link. Up to 8 switching points with different switching modes can also be configured using IO-Link. The actuator diagnosis function of the sensor uses performance data such as piston velocity, piston travel or number of piston strokes to make the processes in pneumatic drives visible.

MPS-M AT A GLANCE

Benefits

-Simple piston position measurement by recording absolute position values within a fixed measuring range of 50 mm

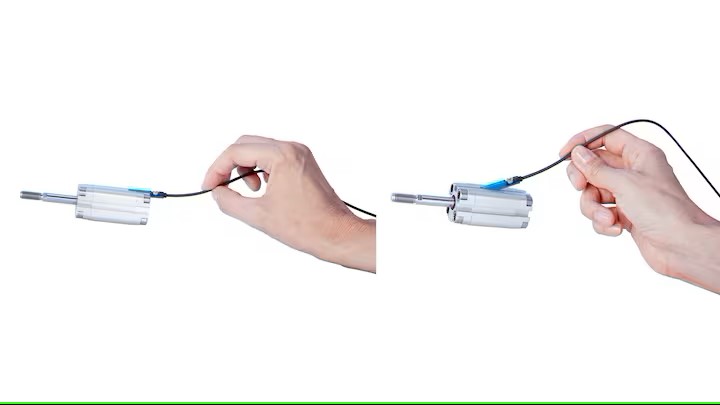

-Quickly and easily mounted on the side or from above in T-slots without dismantling the cylinder end caps

-Simple commissioning without time-consuming parameterization

-Suitable for many applications: Thanks to its compact design, the sensor fits into all common T-slots worldwide regardless of cylinder profile or make

-Quickly and securely fixed in grooves with just a quarter turn of the fixing screw

-Actuator diagnosis function for predictive condition monitoring of pneumatic drives

Features

-For all commonly used T-slots

-Position feedback within a fixed measuring range of up to 50 mm

-Repeatability: 0.05 mm

-Analog interface: 0 V to 10 V

-IO-Link (position measurement, 8 switching points, actuator diagnosis function)

-Actuator diagnosis data: Piston velocity, piston stroke, magnetic field strengths, etc.

-Housing length: 32.5 mm

ADVANTAGES

Precision meets durability

Precision meets durability

As smaller and smaller components are being developed, the miniaturization of production systems is also advancing. That is why the intelligent MPS-M position sensor has a very short housing with a length of only 32.5 mm. It precisely detects the piston positions even in very small cylinders. The rugged housing design of the sensor combined with the proven mounting ensures a correspondingly long service life. The MPS-M is a cost-effective solution that can be used to carry out numerous applications in the mechanical engineering, electronics, solar and automotive industries.

The wear-free measurement principle provides accurate measurement data throughout the entire service life of the sensor.

Two integrated LEDs inform users about the sensor status.

Thanks to the very accurate magnetic displacement measuring system, the compact MPS-M ensures precise piston detection and is a very durable and reliable supplier of data.

Very easy commissioning

The MPS-M can be installed in seconds and is very convenient to use: The compact position sensor can be inserted easily into the T-slots from above or pushed into them from the side and fastened via an eccentric screw with just a quarter turn. This means that the end caps of the cylinders do not have to be disassembled. After sensor assembly, position measurement can start immediately, since neither teach-in nor complicated presetting is necessary. Optionally, up to 8 switching points can be set via IO-Link. This saves valuable time and money and makes sensor integration extremely easy.

Saves time on initial installation and when replacing devices as the sensor can be inserted easy into the slot from the side or above. The end caps of the pneumatic cylinder do not have to be disassembled for this purpose.

Suitable for almost any mounting situation with a housing length of only 32.5 mm and no interfering contours outside the slot.

Plug and play: In just a few steps, the MPS-M is ready for precise position measurement of pistons in pneumatic cylinders.

.jpg)

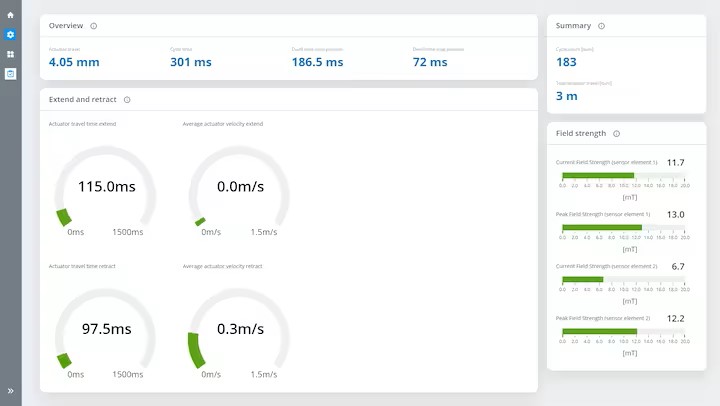

Less production downtime thanks to condition monitoring

The MPS-M increases transparency: It makes processes within pneumatic drives visible thanks to its actuator diagnosis function. With the help of IO-Link, the sensor sends data to the controller, for example on magnetic field strength, piston stroke, cycle times, and piston travel time and velocity. Among other things, the data may indicate possible wear of the actuator. This allows for critical components to be identified, readjusted or replaced early on before unplanned machine downtime occurs.

The MPS-M delivers data for condition monitoring without additional monitoring components.

The data can be displayed quickly and clearly on the dashboard.

More productivity with lower operating costs – the diagnostic data of the MPS-M allows for predictive condition monitoring of pneumatic drives. The advantage is that the risk of machine downtime or failure can be reduced without having to install additional monitoring components.