Features :

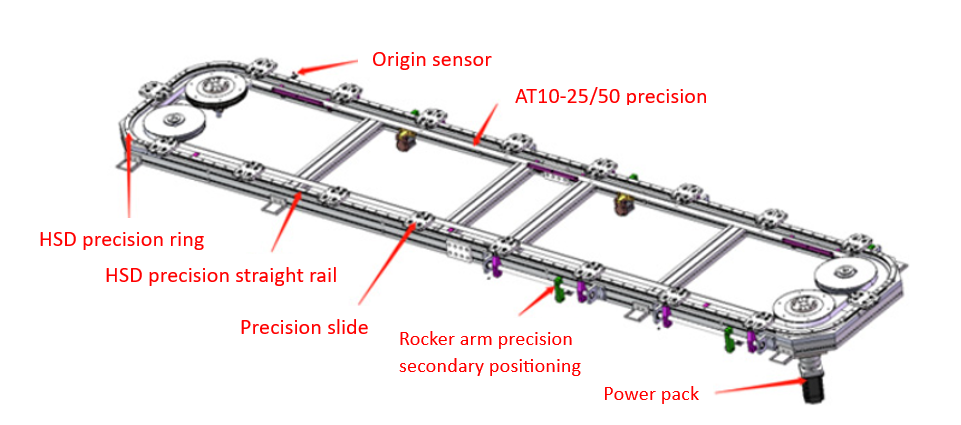

High Precision and Speed: The project incorporates HSD's proprietary V-type track and GMP series components, ensuring high precision, rapid operation, and minimal noise.

Installation Efficiency: The base plate serves as the installation reference, enabling a line body length over 10 meters with fast and convenient installation.

Durable and Reliable Belt System: The project utilizes Huiside's AT10 steel-reinforced synchronous belt, available in 25mm and 50mm widths. For line lengths beyond 8 meters or high-load applications, a 50mm width or thickened belt is recommended. The belt offers strong tensile strength, resistance to breakage, excellent synchronization, and high precision.

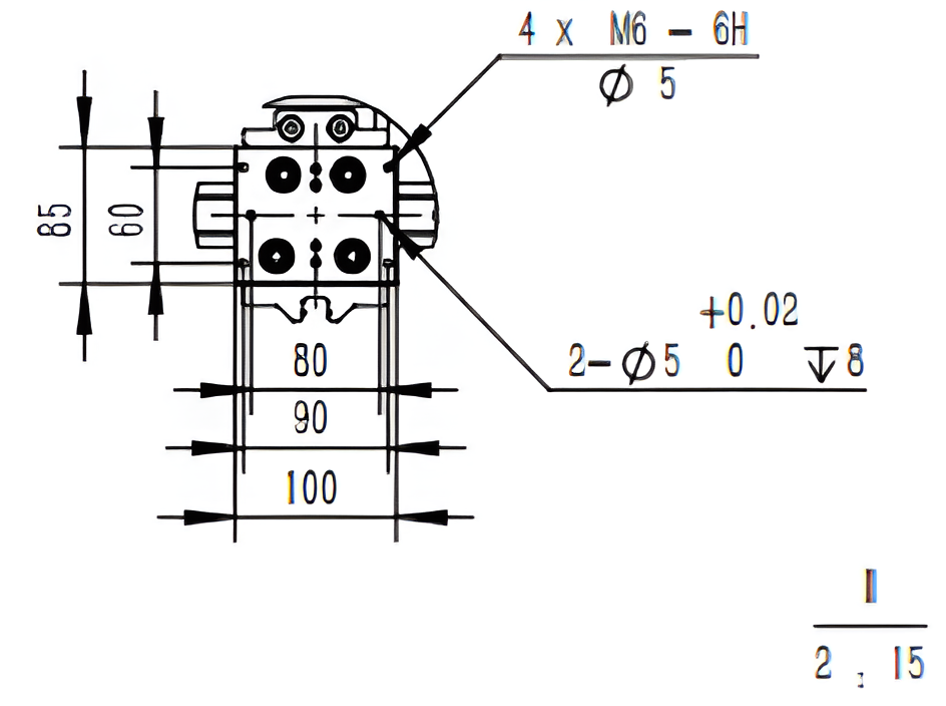

Precise Positioning: A secondary positioning mechanism, designed as a swing arm, provides repeated positioning accuracy within ±0.05mm at any linear or ring rail position. It can be mounted inside or outside the line body, with the project case demonstrating outer positioning.

Stable Motor Control: Servo motors and helical planetary reducers are used, delivering reliable, stable torque and ease of control.

Ideal for Complex, Multi-Station Projects: This line is well-suited for projects involving numerous workstations and intricate processes.

Easy Installation and Adjustment: Ensures accurate setup and easy debugging.

Rectangular Design: Features numerous precision workstations, ideal for spacious environments with ample internal space for both internal and external equipment installation.

Quiet Operation with High Speed and Precision: Delivers low noise, high speed, and precision in performance.

Durable Steel Curtain Belts: Addresses and prevents belt breakage and damage for longer-lasting operation.

Accurate Positioning: Swing arm positioning maintains precise slide repeat accuracy, enhancing overall functionality.

Efficient and Stable Structure: The swing arm mechanism allows easy installation, high efficiency, and high structural integrity and stability of the machine.

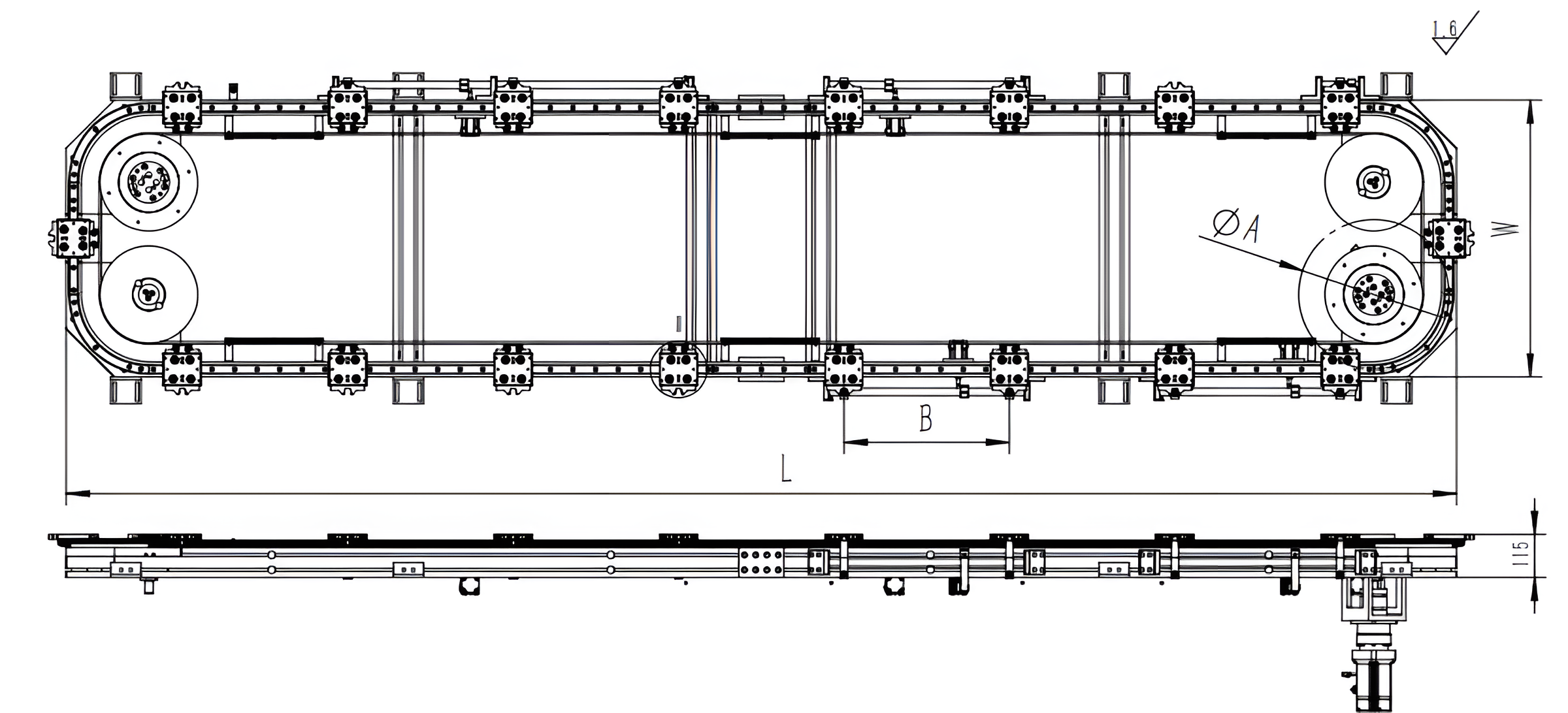

Applicable Ring Rail Sizes: Supports ring rail diameters of φ255, φ300, φ351, φ400, φ468, φ500, φ600.

| Product Name | Rectangular Profile Belt - Swing Arm Positioning |

| Product Model | LOP-RE1-L400-18/10T-S440-SA-HPH |

| Dimensions | 3800*840*230mm |

| Overall structure | Profile base |

| Transmission mode | Steel curtain synchronous belt |

| Installation method | horizontal |

| Ring rail size | 4400 |

| Positioning method | Swing arm type secondary positioning |

| Slide distance | 440mm |

| Slide number/precision station | 18/10T |

| Cutting speed | 1.0-1.25 |

| Single slide bearing | 1.0-10kg |

Malaysia

Malaysia