Overview by DSI Solution | Offered in Malaysia by SYMTRACE

DSI Solution brings over 20 years of expertise in mold and die restoration using advanced pulsed laser welding technology — now available in Malaysia through our official partner, SYMTRACE.

Unlike conventional TIG welding, which often introduces excessive heat leading to deformation, stress, and inconsistent repair quality, pulsed laser welding offers a controlled, low-heat, and precision-based process that protects the integrity of your molds and dies. It’s ideal for fine feature work, deep-area repairs, and critical surfaces, delivering results that are not only durable but often stronger than the original.

We also address a common misconception: pulsed laser welding is not a temporary patchwork — it is a long-term, high-performance solution that restores tooling to its original performance standard, sometimes even exceeding it in terms of wear resistance and surface finishing.

What We Offer

Combining custom-designed laser wires with ultra-precise pulsed welding, we provide solutions for:

• Shape modifications

• Crack and flash repairs

• Ejector pin hole restoration

• Deep area (rib) welding

• Surface finishing (mirror & etching)

• Wear and scaling damage restoration

• Pin-hole (porosity) and fine detail repairs

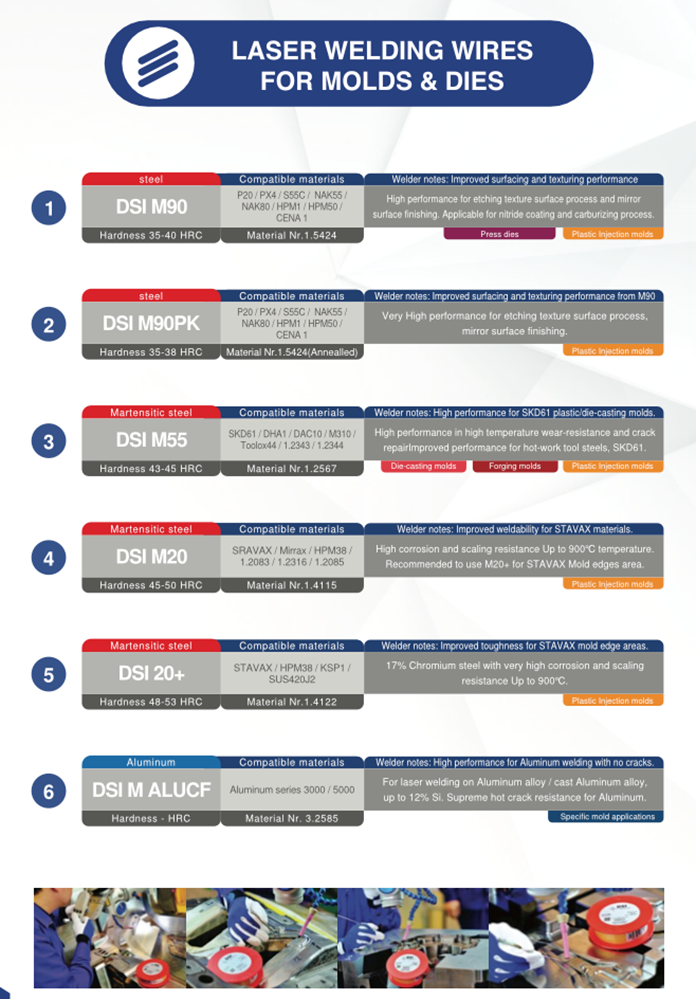

Our Material Coverage

For more information, please refer our Range Wire Datasheet:

https://dsilasermscom.sharepoint.com/:b:/g/EcEPR-z7VGhDh5R-3C9kSLIBZVhXY7p2lYS3V3KEoHlckA?e=EBHChs

Plastic Injection Mold Maintenance

We use DSI M90 and DSI M90 PK “Polish Kraft” wires for:

• Mirror surface and parting line (PL) repairs

• Deep rib welding

• Ejector pin hole repair

• Grain etching surface restoration

Benefits:

• Lower heat input = No distortion

• Polish-ready finish with high grain structure

• Fast high-speed machining post-repair

• Covers roughness grades from #200 to #30,000

• Up to 50% faster maintenance time with no reworks required

Die-Casting Mold Maintenance

Utilizing DSI M70/12, M55, and MAS1C for:

• Crack and wear repair

• Deep deposit welding

• Ejector hole maintenance

• Shape modifications

Advantages:

• No need for pre/post heat treatment

• Hardness increases from 35HRC to 53HRC after aging

• Materials up to 2,400 Mpa tensile strength

• Extend tool lifespan by up to 20% more production shots

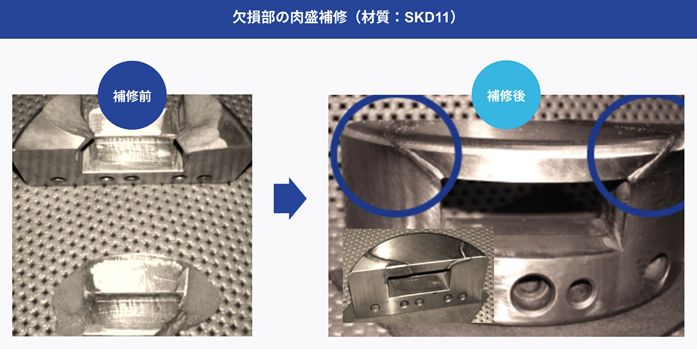

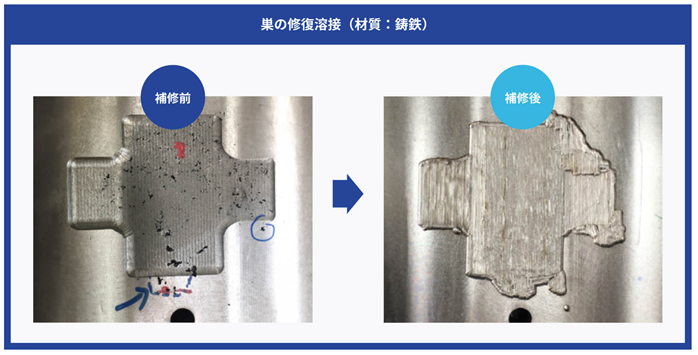

Press Dies Maintenance

Welding under 50°C inter-pass temperature allows safe repair of:

• Heat-sensitive materials (SKD11, cast iron)

• Pinholes

• Cracks

• Dimensional distortion-sensitive areas

Key Strengths:

Room temperature welding, No cold/hot cracking, Custom wire solutions (DSI M90, M10), Excellent for cast iron with porous damage

Malaysia

Malaysia