Features :

| SLABOR | OTHERS | SLABOR' S ADVANTAGES | |

| Hardware | Self-developd Robtic arm | Robtic arm(ABB EPSON FANUC...) | Developed specifically for screw tightening |

| Self-developd Screwdriver | Screwdriver(Desoutter, Bosch, Atlas Copco...) | More adaptable | |

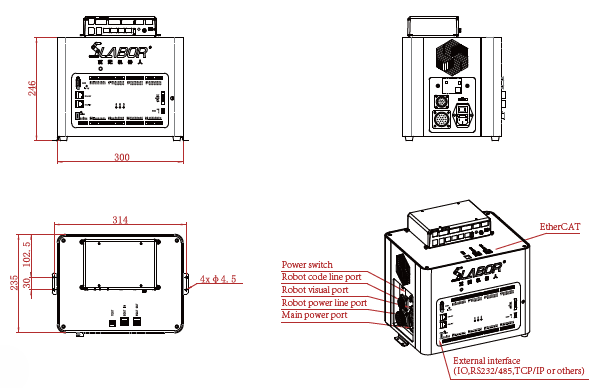

| Self-developd Control cabinat | Touchscreen (SIEMENS, Welnwlew...) | Highly Integrated compact structure with Industrial design aesthetics | |

| Controller(PLC,Control board...) | |||

| Vision system(Hikvision, KEYENCE...) | |||

| Display moniter | Display moniter | ||

| Software | Self-developd Central control software | The robtic arm control program | Highly Integrated Production results are digitized Process results are visualized |

| The overall device logic program | |||

| Operation Interface program | |||

| Visual process program | |||

| Communication | |||

| Human resource input | Connecting gas&power, calibrating the vision system, In can be used | Robotics engineer | Only a short-term erm training is required, and production line workers can quickly adapt |

| Vision engineer | |||

| Electrical engineer | |||

| Software engineer | |||

| Hardware costs | Low | High | Costs are controllable, high cost-effectiveness |

| Design cycle | Quick | Long | Standardized with ample Inventory and short delivery lead times |

| Material return cycle | Quick | Long | |

| Hardware debugging | Installation only | Coordination of all components | Requires minimal debugging and can be quickly deployed on the production line |

| Software debugging | Startup signal noly | Communication between all programs |

Malaysia

Malaysia