Specifications

- Ambient operation temp. max: 60, 70, 50 °C

- Ambient operation temp. min: -30, -35, -10, -40 °C

- Cable material detail: PVC/PTFE coating, PUR, PVC

- Cable material: plastic

- Certificate: EU declaration of conformity, UK declaration of conformity, China-RoHS, cULus certificate, Photobiological safety (DIN EN 62471) certificate, EAC certificate / DoC, MAR declaration of conformity, IO-Link, Laser safety (IEC 60825-1) certificate, ACMA declaration of conformity, ECOLAB certificate

- Communication Interface detail: IO-Link V1.1, COM2 (38,4 kBaud)

- Communication interface: -, IO-Link

- Connection type Detail: Cable with MOLEX-connector, 5-pin, Cable with connector M8, 3-pin, with knurled nuts, male connector M12, 4-pin, Cable, 4-wire, Cable with connector Microfit, 4-pin, Cable with MOLEX-connector, 4-pin, Cable with MOLEX-connector, Cable with Tyco connector, Cable with connector M12, 3-pin, Cable with special male connector, 4-pin, cable with connector RJ10, 4-pin, male connector M8, 4-pin, cable with male connector, cable with Tyco male connector, 3-pin, Cable, 3-wire, cable with special connector, 3-wire, Cable with special connector, Connector M8, 3-pin, Cable with connector M8, 4-pin, with knurled nut, Cable with M8 male connector, 4-pin, Cable with M12 male connector, 4-pin, Cable with connector M8, 4-pin, with knurled nuts, Cable with connector M8, 3-pin

- Connection type: cable, male connector, cable with male connector

- Current consumption: 20 mA, 30 mA, ≤ 20 mA, ≤ 25 mA, 25 mA

- Design detail: Flat, Slim

- Dimension (depth): 17.3, 22.2, 12.1, 12, 18.6, 22.15, 21.8, 22.3 mm

- Dimension (length): 63.2, 39.5, 41.8, 48.5, 41.9, 44.9, 40.1, 48.6, 44.5, 49.2, 42, 55.4, 36.5 mm

- Dimension (width): 12.2, 16, 15.3, 22, 12.1, 15.25 mm

- Distance value output: , Via IO-Link

- Enclosure rating: IP67, IP66, IP69K, IP69, IP68

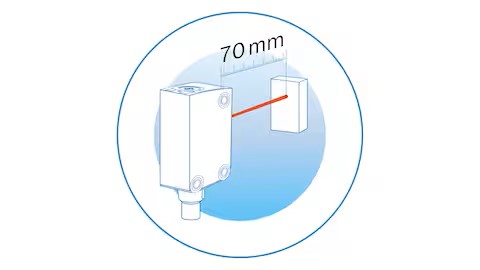

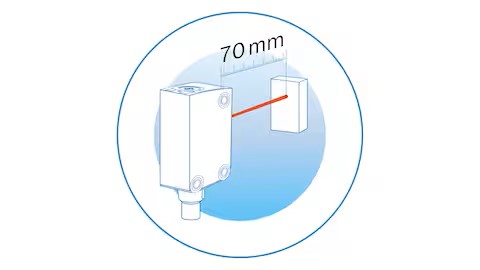

- Focus position: 70 mm

- Functional principle detail: Background suppression, MultiPulse, MultiMode, LineSpot technology, Without reflector minimum distance (autocollimation/coaxial optics), ClearSens, NarrowBeam, MultiSwitch, DoubleLine, Foreground suppression, With minimum distance to reflector (dual lens system), V-optics

- Functional principle: Photoelectric retro-reflective sensor, Photoelectric proximity sensor, Through-beam photoelectric sensor

- Housing material detail: Novodur, zinc diecast, Stainless steel V4A (1.4404, 316L), ABS, PTFE coating, VISTAL

- Housing material: metal, plastic

- Housing: rectangular

- Items supplied: Reflector P250F, 150 x WTB4S-3N1361 (1042046), 50 x WTV4-3N1322S88 (1100125)

- Laser class: 1

- Length of cable: 142 mm, 1400 mm, 5 m, 282 mm, 300 mm, 270 mm, 280 mm, 160 mm, 120 mm, 450 mm, 2 m, 3 m, 10 m, 1.5 m, 77 mm, 1371 mm, 2.5 m, 200 mm, 150 mm, 1000 mm, 100 mm, 0.3 m, 140 mm, 182 mm, 162 mm, 220 mm, 427 mm, 276 mm, 1750 mm, 210 mm

- Light sender detail: PinPoint LED, LED, laser

- Light source: LED, laser

- Light spot size: 6.5 mm (150 mm), 2.5 mm (50 mm), 1.8 mm (70 mm), 7 mm (50 mm), 1 mm, 20 mm (300 mm, 4000 mm), 2 mm (100 mm), 3 mm x 22 mm (40 mm), 1 mm (500 mm), 20 mm (40 mm), 6.2 mm x 4.4 mm (30 mm), 75 mm (2 m), 35 mm (1.5 m), 4 mm (120 mm), 7 mm x 5 mm (20 mm), 7 mm x 5 mm (50 mm), 100 mm (2.5 m), 75 mm (1.5 m), 55 mm (1.5 m), 1.4 mm x 19 mm (50 mm), 4.2 mm (130 mm), 0.5 mm x 1.9 mm (30 mm), 2.5 mm (150 mm), 1 mm (170 mm), 0.4 mm (60 mm), 4 mm (100 mm), 3 mm x 20 mm (40 mm), 25 mm (200 mm), 2 mm (50 mm), 5 mm x 28 mm (50 mm), 50 mm (2 m), 1.2 mm x 17 mm (50 mm), 4.4 mm (130 mm), 2 mm x 2 mm (50 mm), 38 mm (1000 mm), 60 mm (2 m), 4 mm (150 mm), 22 mm x 300 mm (1000 mm), 150 mm (5 m), 6.5 mm (70 mm), 2.5 mm x 16 mm (50 mm), 2.5 mm (100 mm), 40 mm (1000 mm), 7 mm (40 mm), 45 mm (1.5 m), 3.5 mm (40 mm), 10 mm (40 mm)

- Mounting hole: M3

- MTTFD: 1103 a, 1222 a, 1601 a, 1221 a, 1166 a, 1232 a, 1211 a, 1180 a, 1668 a, 1353 a, 1231 a, 647 a, 1423 a, 1071 a, 643 a, 441 a, 420 a, 444 a, 423 a, 1365 a, 1530 a, 753 a, 1138 a, 1215 a, 1219 a, 1347 a, 708 a, 938 a, 1212 a, 868 a, 642 a, 1390 a, 1119 a, 1044 a, 968 a, 2700 a, 1318 a, 326 a, 1407 a, 589 a, 350 a, 440 a, 1186 a, 1160 a, 1403 a, 1187 a, 574 a, 1124 a, 1143 a, 2983 a, 661 a, 747 a, 1053 a, 663 a, 445 a, 1063 a, 715 a, 1179 a, 575 a, 683 a, 1064 a, 1404 a, 1375 a, 616 a, 655 a, 873 a, 1023 a, 3291 a, 1008 a, 3027 a, 355 a, 1956 a, 1590 a, 562 a, 417 a, 1078 a, 1399 a, 893 a, 1770 a, 1263 a, 582 a, 424 a, 1194 a, 1351 a, 693 a, 405 a, 1368 a, 1346 a

- Number of digital outputs: 2, 1

- Object distance (max.): 47, 165, 3500, 56, 100, 280, 300, 1600, 4500, 2000, 150, 9000, 22, 95, 4800, 4000, 120, 130, 55, 50, 60, 900, 250, 80, 1500, 12000, 200, 48, 180, 500, 60000, 10000, 140, 3000, 220, 5000, 70, 25, 7100 mm

- Object distance (min.): 3, 2, 15, 28, 20, 400, 100, 6, 8, 22, 7, 4, 9, 0, 35, 25, 10, 40, 30 mm

- Output function: Complementary

- Output: Health output, Alarm output, Simple switching output, Contamination alarm VMA

- Product family: W4

- Product segment: Photoelectric sensors

- Response time: ≤ 15 ms, < 2 ms, ≤ 0.33 ms, ≤ 500 s, ≤ 50 ms, ≤ 1000 s, < 0.1 ms, < 2.5 ms, < 1.2 ms, < 330 s, < 0.65 ms, ≤ 0.5 ms, < 0.25 ms, < 0.5 ms, ≤ 0.1 s, ≤ 0.5 s, < 1 ms, ≤ 650 s, ≤ 1 ms, < 2.4 ms

- Sensing range max.: 0 ... 150 mm, 150 ... 500 mm, 7 ... 12 m, More than 45 m, 2 ... 4 m, 1 ... 2 m, 12 ... 20 m, 500 ... 1000 mm, 4 ... 7 m

- Sensing range: 4 m, 165 mm, 500 mm, 22 mm, 0.9 m, 4.5 m, 55 mm, 3.5 m, 2 m, 1.6 m, 3 m, 1.5 m, 50 mm, 280 mm, 60 mm, 100 mm, 60 m, 0.07 m, 120 mm, 140 mm, 9 m, 200 mm, 250 mm, 5 m, 180 mm, 300 mm, 12 m, 150 mm

- Setting Method: for configuring the sensor parameters and Smart Task functions, For setting the sensing range, For deactivation of the sender and execution of test logic, for sensitivity adjustment, , Teach-in plus user mode selector, For adjusting the sensing range with mode selection

- Shape of light spot: Line-shaped, rectangular, DoubleLine, Point-shaped

- Signal voltage NPN HIGH/LOW: approx. UB / < 2.5 V

- Signal voltage PNP HIGH/LOW: Approx. UB-2.5 V / 0 V

- Smallest detectable object (MDO) typ.: 0.2, 1, 0.1, 0.6, 0.7 mm

- Smart Sensor: Enhanced Sensing, diagnosis, Smart Task, efficient communication

- Smart Task name: Object and gap monitoring, Time measurement + debouncing, Counter + debouncing, timestamp + debouncing, Speed and Length Monitoring, base logics

- Special applications: Detecting transparent objects, Detecting small objects, Detecting flat objects, Detecting objects wrapped in film, Detecting perforated objects, Hygienic and washdown zones, Detecting uneven, shiny objects, Detecting objects with position tolerances, Detection of poorly remitting and tilted objects

- Special feature: M12 adapter thread, sensing range preset: 22 mm, V-optics, Line-shaped light spot, visible light blocking filter, D12 adapter shaft

- Special features: Health output, special hysteresis, ON delay pre-set: 50 ms, sensing range preset: 94 mm, Small light spot diameter of 2 mm at distance of 100 mm, aperture on front screen for the detection of plastic bottles, AMP-connector, Valid for all sensors from date code 1245, Pinhole 2 mm on front screen, Reduced sensitivity, Off delay 16 ms, ON delay pre-set: 16 ms, without sensing range lock, teach-in button lockable, no adjustment possibility, foreground suppression up to 15 mm, 1.2 ms one-shot output, visible light blocking filter, detection of deep blue solar cells, PIN 4: dark switching, PIN 2: light switching, fixed sensing range 120 mm, Continuous threshold adaption on - time based, ON delay pre-set: 30 ms, sender, line-shaped light spot, IO-Link (optional), Sensing range pre-set: 100 mm, Special front-side sealing, light spot diameter of 2.5 mm in 150 mm distance, fixed sensing range 80 mm, fixed sensing range 95 mm, on delay 200 ms on pin 2, fixed sensing range 3 ... 25 mm, Pin 2 , higher sensitivity, 50% hysteresis, MultiPulse: sensor with self-monitoring, larger close-up range, fixed sensing range 48 mm, Teach-Turn adjustment deactivated, fixed sensing range 28 … 165 mm, Tyco-connector, vertical slotted diaphragm, reduced sensing range of 280 mm, fixed sensing range 100 mm, Printed lens, fixed sensing range 30 ... 100 mm, Dark switching, fixed sensing range 28 ... 80 mm, receiver, light/dark switching via single Teach-in button, indicator LED follows output, Sensing range: preset 117 mm, Cable with connector M8, 4-pin, with knurled nuts, reduced sender current of 2 mA, fixed sensing range 28 … 50 mm, Auxiliary sensor (e.g. WL4S-3P2232, 1042078), Smart-Sensor Y-junction SYL-8204-G0M11-X2 (6055012), 2 x connecting cable (e.g. YF8U14-C60VA3M8U14, 2096612), 2 x reflector (e.g. P250F, 5308843), Printed front screen for increased blind zone, sensing range preset: 22 mm, with external teach (ET) on PIN 2, Light/dark switching via teach-in and ET (when switched off), sensing range preset: 56 mm, Deactivation delay, 15 ms (± 5 %), Pin2 pre-setting (MF): alarm output, The difference to the standard device is that WTB4S-3K2261 , 1047804 has a swapped complementary output: Q/ and Q instead of the usual Q and Q/, swichting frequency 2.000 Hz, Pin 2 not connected, On delay pre-set: 200 ms, Printed mask on front lens, Adjustable OFF delay, Light switching, without polarisation filter, Sensor for Safeguard Detector safety system, fixed sensing range 4 ... 60 mm, Pin2 pre-setting (MF): external input, MultiMode, fixed sensing range 30 ... 150 mm, Sensing range: preset 60 mm, Slotted diaphragm 2 mm in front of sender, off delay 100 ms, switching output pin 2 inverted, Deactivation delay, 30 ms, Sensing range pre-set: 140 mm, Functions compatible with WLG4SC-3P2232A91, Sensing range: preset 104 mm, With DEK mounting bracket, Parameter presettings: 200 ms on delay on QL1, Connection cable 2 m, Sensing range: preset 120 mm, maximum sensing range of 1.5 m, Sensing range: preset 105 mm, small light spot, Sensor with Smart Task function “time stamp”, pre-setting Smart Task: OR operation, Complementary switching outputs, Stainless steel surface can be used as reflector, fixed sensing range, parameter (pre-setting), Foam protection frame on front screen, Front screen printing, reduced sensing range, Inverter 1 , 2 ms one-shot output, External teach, Cable with special connector, Pin2 pre-setting (MF): teach-in via cable, Point-focused light spot at 150 mm, switch-off delay, 32 ms, incl. Mounting bracket, Parameter presettings: interter 1 , Pin2 pre-setting (MF): not active

- Sub product family: W4SL-3H, W4S, W4F, W4-3, W4-3 Glass, W4-3 PTFE, W4S-3 Inox, W4S-3 Inox Glass, W4S-3 Inox Hygiene, W4SLG-3H, W4S-3 Inox Hygiene Glass, W4SL-3, W4SLG-3V, W4SLG-3, W4SL-3V

- Switching frequency: 2000 Hz, 30 Hz, 750 Hz, 5000 Hz, 500 Hz, 600 Hz, 200 Hz, 1000 Hz, 2 Hz, 1500 Hz, 10 Hz, 20 Hz

- Switching mode selector: programmable

- Switching mode: Light switching, Dark switching, Light/dark switching

- Switching output detail: PNP, push-pull: PNP/NPN, NPN

- Switching output: Push-pull, PNP, NPN

- Task: Detecting - Transparent objects, Detecting - Standard objects, Detecting - Perforated objects

- Type of digital output: individually adjustable, Complementary

- Type of light: visible red light, Infrared light

- Voltage type: DC

- Weight: 40 g, 140 g, ca. 30 g, 100 g, 30 g, 20 g, 80 g, 57 g, 45 g, 180 g, 50 g, 60 g, 125 g

Description

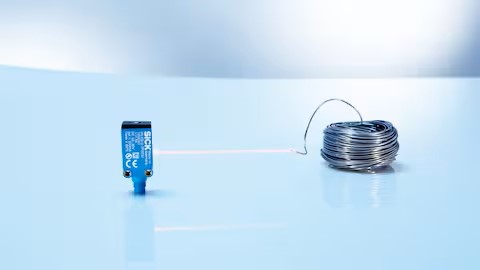

Powerful miniature photoelectric sensors and photoelectric proximity sensors for automation

W4 miniature photoelectric sensors and photoelectric proximity sensors are the ideal solution for the intelligent automation of industrial processes. The powerful sensors in the miniature housing reliably detect glossy, flat, uneven, perforated and transparent objects and detect a wide range of parameters such as remission and distance values. Due to the selection of different designs, housing materials and light sources, the sensors are well-suited to countless applications and nearly any assembly situation. The profile is rounded out with an intuitive operating concept and intelligent diagnostic functions.

W4 AT A GLANCE

Benefits

-Fault-free system operation thanks to rugged and reliable object detection

-Space-saving assembly options and high flexibility in machine design thanks to different sizes

-Wide range of application possibilities due to various housing materials

-Solution for challenging detection tasks thanks to different light sources

-Powerful process control and increased machine productivity

-High user-friendliness thanks to quick and convenient commissioning and operation

Features

-Intelligent sensor performance for nearly any application

-Housing available in either a “slim” or “flat” design

-Optionally with VISTAL or stainless-steel housing

-Light source: Laser red light, infrared or PinPoint LED

-Smart Sensors with innovative monitoring and diagnostic functions

-Intuitive operating concept

ADVANTAGES

.jpg)

Diverse application possibilities thanks to different product variants

W4 photoelectric sensors are characterized by the range of individual variants available. With the ability to select from a variety of designs, you can obtain the most suitable sensor for your specific installation situation. Thanks to the compact sensor housing, the different designs can be integrated easily and in a space-saving manner even in very tight installation spaces. The availability of a variety of housing materials also opens up numerous applications. You also have freedom of choice when it comes to the light source. No matter what your particular application, SICK offers a reliable solution to precisely suit your specific requirements.

W4 sensors are available in either a Slim or Flat design. The standardized mounting ensures uncomplicated installation regardless of the design selected.

The sensors come with a housing made from either VISTAL or stainless steel. A hygienic stainless steel version is available for applications in sterile environments.

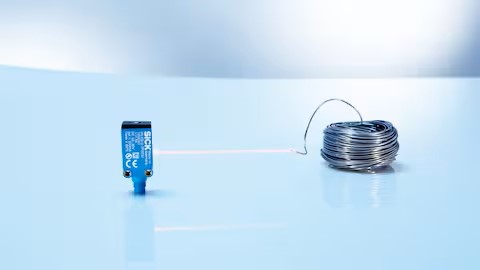

Red laser light provides the ideal basis for detecting even very small objects. The other light sources available are the highly-visible PinPoint LED, or an infrared LED.

Various designs, housing materials and light sources provide a great deal of flexibility when selecting the most suitable sensor for your needs

Impressive detection results in countless applications

Impressive detection results in countless applications

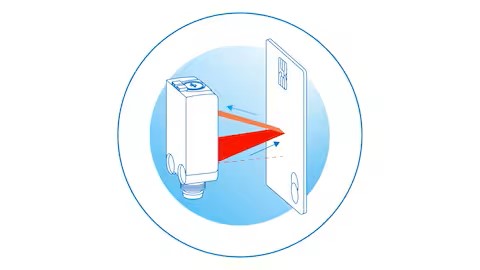

Thanks to the integrated ApplicationSelect mode, the sensor functions can be adapted to the specific requirements of the application. Even objects in an oblique orientation or with a low remission factor can thereby be reliably detected.

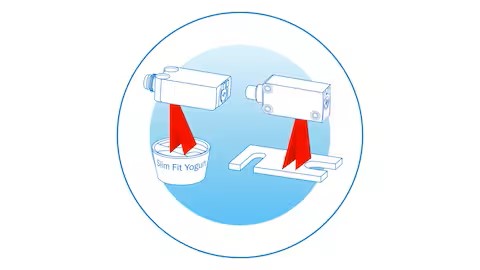

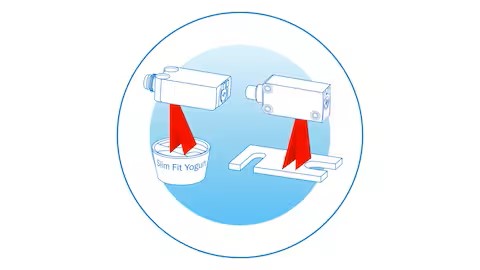

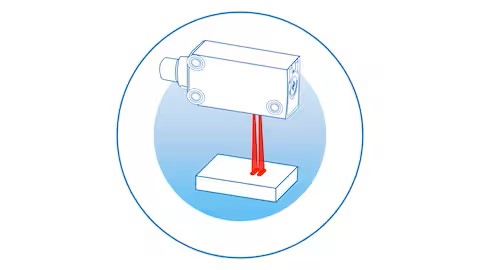

The LineSpot technology ensures perforated, textured, and uneven objects can be reliably detected.

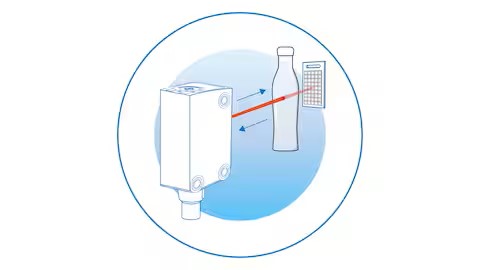

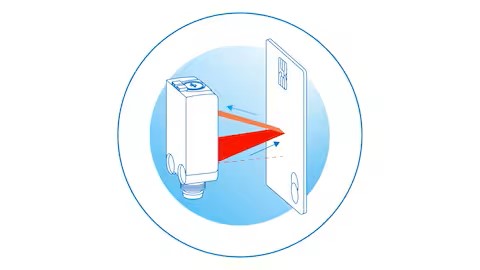

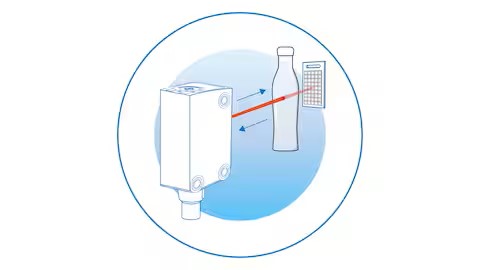

In the case of transparent objects such as glass bottles or cling film, the ClearSens technology guarantees reliable detection results.

The sensors can provide the distance value in millimeters and the remission value of the detected object via IO-Link.

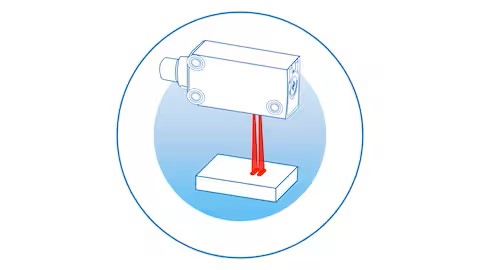

Thanks to foreground suppression, the sensors reliably detect very flat, poorly remitting, reflective, and uneven objects.

The integrated v-optics technology helps the device detect highly reflective and transparent objects such as wafers or displays by means of a very small, laser-like light spot.

Thanks to innovative technologies, the sensors can solve the most demanding detection tasks in almost any application regardless of the object properties

High user-friendliness through easy commissioning and operation

Besides their high detection reliability, the latest generation of W4 photoelectric sensors stand out on account of their particularly easy handling. Thanks to the intuitive BluePilot operating concept, the sensors can be configured in a matter of seconds via a push-turn mechanism and tailored to the specific application. A blue LED indicator gives you immediate feedback on the optimal alignment of the sensor. If the detection quality drops due to contamination or vibrations, you are alerted to this via a well visible LED. This enables malfunctions to be correctly early, and unplanned system downtimes to be avoided.

Using a combination of teach-in button and potentiometer, the required settings can be easily configured directly on the device

The blue LED alignment aid accelerates the process of optimally aligning the sensor, and indicates any changes in the operational safety at a glance

Thanks to the intuitive operating concept, the mode selection can be effortlessly performed and read directly on the device

The BluePilot operating concept allows convenient commissioning of the sensor in just a few seconds. The operating concept also minimizes the risk of unplanned downtimes.

Increased productivity thanks to innovative functions

The latest generation of W4 photoelectric sensors acquire a variety of performance parameters such as temperature, operating hours, remission values and distances values. The acquisition of these parameters provides the foundation for automated condition monitoring, which enables unplanned downtimes to be avoided. You can also flexibly and precisely tailor the sensor settings to your application. Condition monitoring and adjustments help increase your machine productivity. W4 photoelectric sensors therefore offer a future-proof solution for your system.

Innovative monitoring and diagnostic features allow powerful process control and thereby increase the machine productivity

More detail about Truserv Technologies (M) Sdn Bhd

.jpg)

Impressive detection results in countless applications

Impressive detection results in countless applications