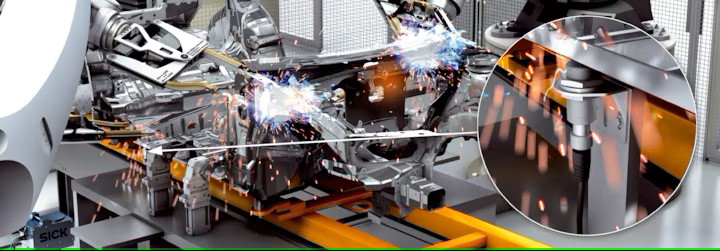

Reduction factor 1 sensors for welding applications

The IMR inductive proximity sensors are not the least bothered by magnetic interference fields or weld spatter, such as arise in resistance welding applications. IMR sensors are made without a ferrite core, which makes them magnetic field resistant, and also have a very high electromagnetic compatibility. Thanks to the rugged non-stick coating made from PTFE, these sensors provide very good protection against flying sparks and slag deposits, thereby guaranteeing a high operational safety. Since IMR sensors operate on the reduction factor 1 principle, they can detect all metals within the same sensing range. The very high sensing ranges of up to 75 mm help reduce mechanical damage to the sensors and therefore sensor failures, and increase plant availability.

IMR AT A GLANCE

Benefits

-Switching errors due to electromagnetic fields are precluded

-Long service life, even for welding applications with stringent requirements, thanks to the special PTFE coating

-Extra large sensing range for all metals, e.g. Aluminum or stainless steel, reduces mechanical damage to the sensors and therefore sensor failures, and increases machine availability

-Simple and reliable detection of objects made from different metals

-Reliable even under harsh ambient conditions thanks to the extended temperature range and an IP68 enclosure rating

-Cylindrical design with high switching frequencies for fast automation processes

Features

-Types: M8 to M30, 40 x 40 mm and 80 x 80 mm

-Increased sensing range: up to 75 mm

-Electrical configuration: DC 3- and 4-conductor

-Enclosure rating: IP68

-Temperature range: –30° C to +85° C

-PTFE coating for cylindrical thread designs

-Reduction factor 1 for all metals

ADVANTAGES

Reduction factor 1 for all metals

Reduction factor 1 for all metals

The IMR inductive proximity sensors with reduction factor 1 offer uniform sensing ranges on all non-ferrous metals such as aluminum or stainless steel. Due to the combination of reduction factor 1 with the increased sensing ranges of the IMR, the sensors detect objects at a distance up to 3 times what the standard prescribes.

Safe detection of all metals at the largest possible distance

The same sensing range on all metals thanks to reduction factor 1

Thanks to the threefold sensing ranges of up to 75 mm, the IMR sensors detect every object from a safe distance

IMR proximity sensors with reduction factor 1 detect non-ferrous metals at the largest possible distance, thereby increasing plant availability

Very high magnet field and welding field strength

Very high magnet field and welding field strength

Since they do not contain ferrite cores, IMR proximity sensors are resistant to strong magnetic fields such as those they occur with resistance welding. The use of the most up-to-date ASIC technology also results in excellent EMC sensor properties. That is why they are the first choice not only for use in the automotive industry. The rugged PTFE non-stick coating of the metal sleeves and the use of resistance Duroplast plastic reliably prevents weld spatter from sticking. IMR proximity sensors are therefore optimally designed for long-term use in welding areas with strict requirements.

Best selection for welding applications

Electrical and mechanical welding field strength for long service life

Thanks to a temperature range of –30 °C to 85 °C and enclosure rating IP68, they are optimally suited for any use

IMR proximity sensors are perfectly designed for challenging welding applications