Efficient all-rounder for precise distance measurements

The compact OD2000 displacement measurement sensor is a very economical stand-alone solution for accurate distance measurement. The universally applicable sensor is suitable for a wide variety of applications with distances of up to 1,200 mm. Using high-precision triangulation, it detects even the smallest differences in height in the micrometer range. Due to top values in terms of linearity and repeatability as well as a measuring frequency of up to 7.5 kHz, the OD2000 delivers reliable distance data on virtually any surface. Thanks to the plug and play concept, the sensor can be integrated very quickly. In addition, configuration via the OLED display on the sensor or via IO-Link interface and software is extremely convenient.

OD2000 AT A GLANCE

Benefits

-Optimizes the process quality due to high repeatability and linearity throughout the entire measuring range

-Universally applicable thanks to precise measurement results on virtually any surface, regardless of its texture or color

-Reliable distance values in every application thanks to intelligent measured value filters and evaluation algorithms

-Very economic solution, even for demanding applications

-Simple and convenient configuration via OLED display or software

-Quick commissioning thanks to intuitive operating concept

-Enables high production throughput thanks to a high measuring frequency

Features

-Large measuring range of up to 1,200 mm

-High measuring frequency of up to 7.5 kHz

-OLED display for easy parameterization on the sensor

-IO-Link interface for configuration, e.g. with SOPAS

-Adjustable analog output (mA/V) and digital output

-Laser classes 1 and 2

-Stand-alone device – no external amplifier required

ADVANTAGES

Precision meets quality

Precision meets quality

With expert-developed intelligent measurement technology which proves its worth in industrial applications time and time again, SICK offers the solution to any challenge which demands maximum measurement accuracy and quality. A pioneering spirit founded on our years of experience and our own innovations in optical sensor technology. We ensure efficient processes while fulfilling the demands of even complex measuring tasks – regardless of surface, diameter, thickness, or width, and regardless of whether an object is to be positioned or measured. This is how we ensure that your products are every bit as perfect as you want them to be. Moreover, SICK’s measurement technology supports quality assurance processes and delivers cost-saving benefits.

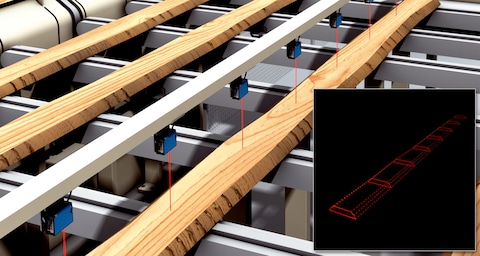

A point of light is projected onto the measuring object. The light reflected is captured by a light-sensitive receiver at a specific angle. Based on the angle between the send and receive direction, the position of the object is then triangulated (from the Latin “triangulum” = triangle).

.jpg)

Seamless system integration via IO-Link

Seamless system integration via IO-Link

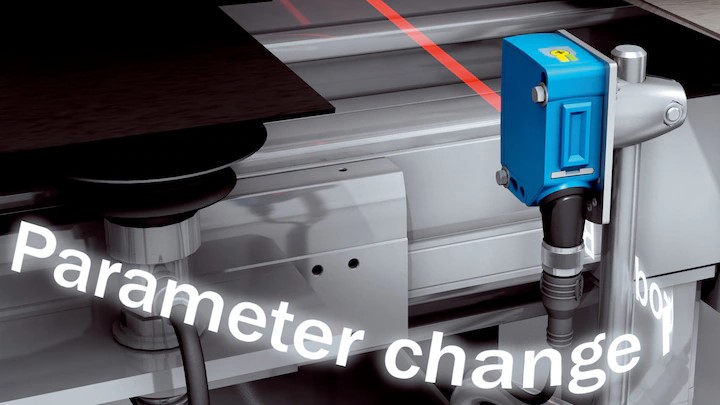

The OD2000 offers both an analog and a digital output signal. Point-to-point communication via the IO-Link interface is what makes the displacement measurement sensor intelligent. In addition to increased reliability due to interference-free signal transmission, the technology primarily scores points for its potential in process automation. A wide range of diagnostic options simplify sensor monitoring and at the same time increase availability for production.

Easy device replacement:

Parameterization via IO-Link accesses existing data, preventing incorrect settings.

More options for condition monitoring:

With process and extended diagnostic data, IO-Link offers extensive information in real time that in turn provides information about the sensor status.

Precise real-time data for automation: Thanks to IO-Link, the OD2000 communicates with the system and creates the foundation for predictive maintenance with its process and status data.

Connect and get started thanks to plug and play sensor exchange

Direct parameterization via IO-Link and the configuration software simplify integration, especially when mounting in poorly accessible places. If a sensor has to be replaced, the plug and play principle of the OD2000 minimizes plant downtime and personnel costs by automatically importing parameterization data. Replacing the sensor itself is child’s play.

One displacement measurement sensor, countless possibilities

One displacement measurement sensor, countless possibilities