Slim, intelligent, intuitive to operate – universal solution for label detection

The innovative, small UFS fork sensor from SICK allows space-saving installation, for example directly on the dispensing edge of a labeling machine. Thanks to ultrasonic technology, the UFS reliably detects a variety of labels on carrier material – regardless of their color, pattern, marking, transparency level and gloss level. It flawlessly detects even very small label gaps of just 1 mm in size. And the display shows its actual operating reserve at a glance. The IO-Link communication interface also opens up numerous possibilities such as fine adjustment, analyses and monitoring, e.g., for automatic reporting of a web tear, as well as teach-in and sensor configuration during the running process.

UFS AT A GLANCE

Benefits

-Space-saving installation thanks to the slim housing

-High process accuracy because belt flutter is minimized when installed on the dispensing edge

-High process reliability through ultrasonic technology that prevents false detections due to gloss or ambient light

-Reduction in waste because the detection of very small separations (1 mm or higher) allows more labels to fit on the carrier material

-Fast and easy commissioning through direct feedback on the quality of the teach-in or run via a bar graph

-Reduces downtimes because teach-in and adjustments can be performed during the running process via IO-Link

Features

-Small housing with especially slim lower flange (5.5 mm high)

-Detects numerous labels and films – even transparent materials

-Detects label separations of 1 mm and greater

-Display shows teach-in quality and operating reserve

-Intelligent sensor with integrated IO-Link interface

ADVANTAGES

Simple integration into compact machine designs

Simple integration into compact machine designs

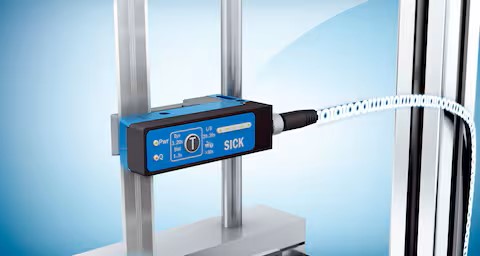

The particularly slim housing of the UFS allows for space-saving installation directly at the dispensing edge. The advantage: higher process accuracy due to minimization of web flutter. The UFS is the first ultrasonic fork sensor with a lower flank height of only 5.5 mm. In spite of its compact design, the sensor is compatible with the mounting systems of the UFN and WFS variants.

Compact size: with a lower flank height of only 5.5 mm, the UFS is significantly slimmer than comparable ultrasonic fork sensors.

Efficient processes: minimal web flutter by installing directly at the dispensing edge.

Easy changeover: the compact housing make it possible to change from an optical detection solution to ultrasonic technology without adapting the fixture.

Integrate the UFS into countless applications in which ultrasonic fork sensors could not previously be used due to space limitations.

Detects a wide range of labels

Detects a wide range of labels

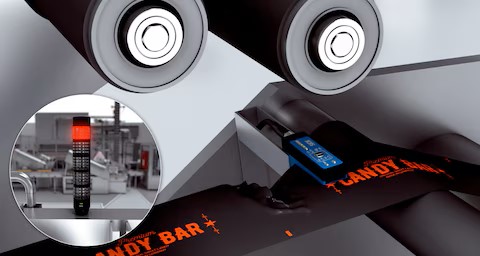

Due to its powerful ultrasonic technology, reflective and transparent materials are no problem for the UFS. The fork sensor distinguishes labels from the carrier material based on their signal attenuation: labels on carrier material dampen the signal more than the carrier material alone. This means that even labels that cannot be detected by optical solutions are identified.

Stable processes: gloss and ambient light pose no problems whatsoever for ultrasonic technology. Even transparent, reflective or deep black labels can be detected easily.

Diverse optical properties: regardless of patterns, colors and labeling, the UFS reliably distinguishes labels from the carrier material.

High material efficiency: even very small label gaps from 1 mm can be detected by the UFS without error at up to 2.2 m/s.

The UFS fork sensor with ultrasonic technology detects optically challenging labels as well as very small distances between the labels (1 mm or higher).

.jpg) Smart detection thanks to IO-Link

Smart detection thanks to IO-Link

The UFS is a smart sensor with IO-Link. The integrated communication interface enables quick configuration during operation, eliminating the need for local access to the sensor. Format changes, fine adjustments, analyses and monitoring are also convenient via IO-Link.

Smart integration: IO-Link allows for easy parameterization of the sensor and convenient adjustment of the settings during operation.

Continuous monitoring: the UFS constantly sends current process data via IO-Link, which can be used for automatic reporting of upset conditions and predictive maintenance planning.

Individual adaptation: the SOPAS configuration software can be used to make a large number of additional settings.

Thanks to IO-Link and diagnostic functions, the UFS reduces the risk of downtime with the high detection quality at the same time thanks to individual sensor settings.

Sensor performance always in view

Sensor performance always in view

The quality of the teach-in can be checked via the bar graph on the sensor display. During operation, the display indicates the stability of the detection performance (Quality of Run) at a glance. This makes it possible to see at any time whether the sensor is set properly or needs to be readjusted.

Quick commissioning: the bar graph allows the UFS to be parameterized to suit the respective application.

Simple on-site monitoring: you can see at a glance if maintenance is required or if settings need to be adjusted.

Malaysia

Malaysia