Features :

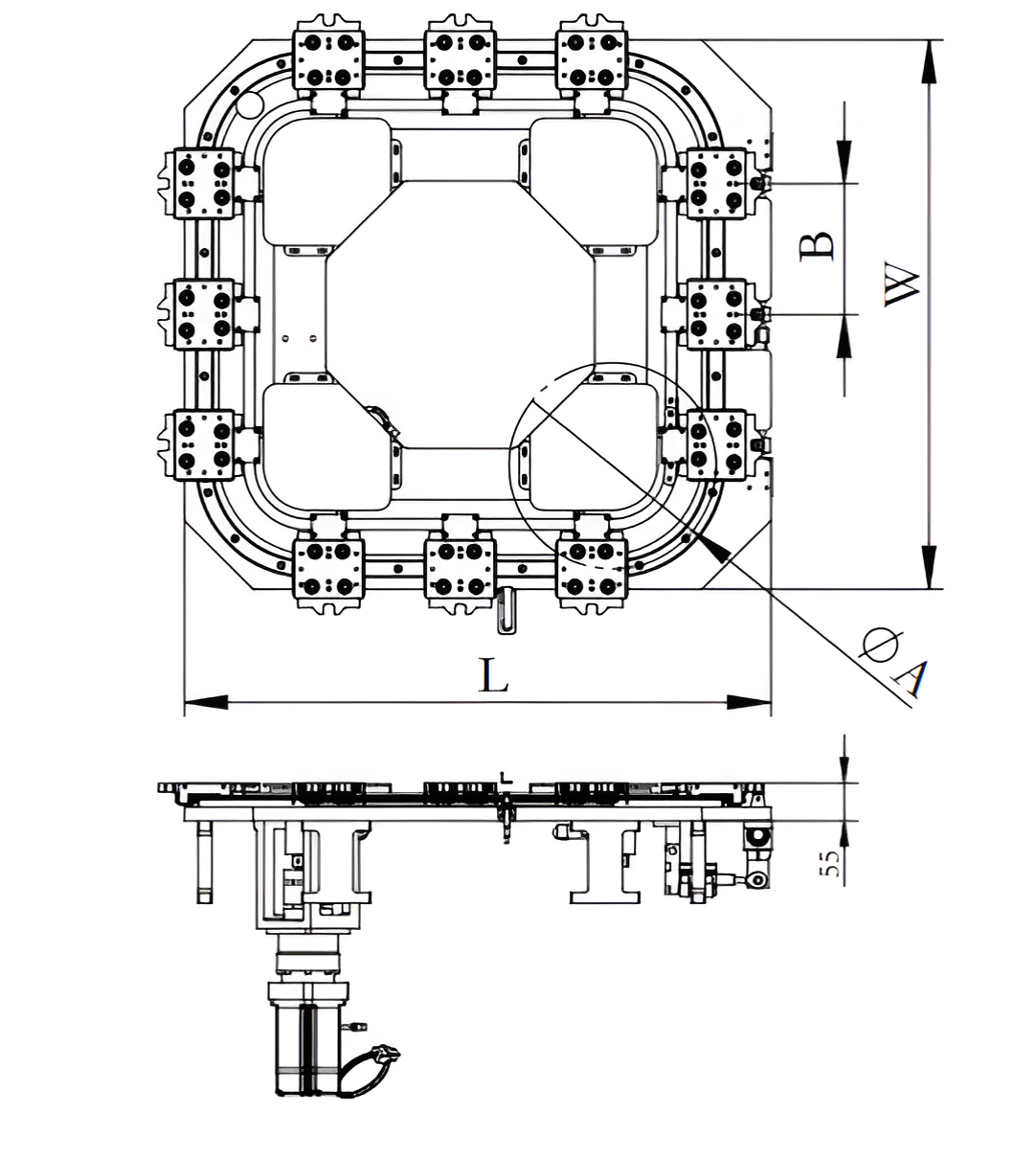

Installation Reference and Modular Design: The bottom plate serves as the installation reference point. For line bodies under 2.5 meters, a single plate is used, whereas line bodies over 2.5 meters utilize a split plate design for easy assembly and installation.

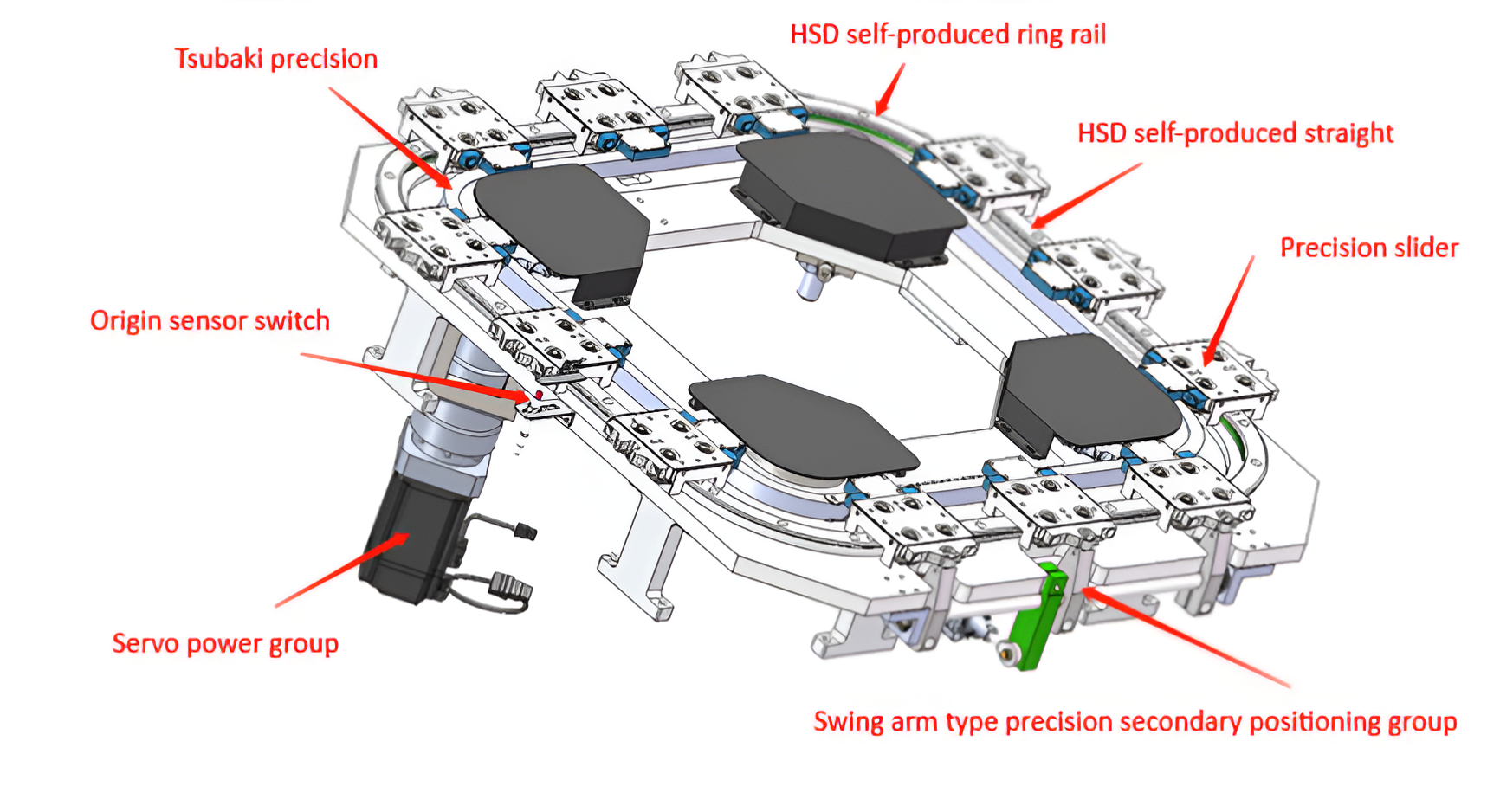

Durable AT10 Steel Curtain Belt: Huiside’s AT10 steel curtain belt, with a width of 25mm, is highly durable, resistant to breakage, and offers excellent synchronization and precision. Available in contoured tooth and belt buckle connection types to fit different application needs.

High-Accuracy Positioning Mechanism: A secondary cylinder swing arm positioning mechanism allows installation at any workstation, ensuring repeat positioning accuracy of ±0.05mm. This mechanism can be placed on either side of the line body for added versatility.

Robust Drive System: Equipped with a 750W servo motor and helical planetary reducer, the line body provides stable, reliable torque output and is easy to control.

Optimized for Light Loads and High Speeds: Suited for projects requiring rapid operation with smaller load capacities, making it ideal for efficient and streamlined production setups.

| Product Name | Rectangular Base Chain - Swing Arm Positioning |

| Product Model: | LOP-RE2-L300-12/3T-S190.5-SA-HPH |

| Overall dimensions | 890*875*212mm |

| Overall structure | Base plate |

| Transmission mode | Base plate |

| Installation method | Horizontal |

| Positioning method: | Swing arm positioning |

| Ring rail size | 4300 |

| Slide distance | 190.5mm |

| Slide number/precision station | 12/3T |

| Cutting speed | 1.0-1.55 |

| Single slide bearing | 1.0-15kg |

Malaysia

Malaysia