MSP METROLOGY was one of the Standard Malaysia Accreditation laboratories ( under no: SAMM 1066) to provide on-site calibration services. Reading correction during calibration consider one of our strengths in this market. We are also the one of laboratories in Malaysia to be accredited with JIS and ASTM standards for Hardness Tester. Our expertise will ensure you get more professional services, perform equivalent to manufacturer standards, and provide consultation if necessary.

Why calibration is important?

The accuracy of all measuring device degrades over time. This is typically caused by normal wear and tear. However, changes in accuracy can also be caused by electrical or mechanical shock or even hazardous manufacturing environment (e.g., oils, metal chips etc.).

Depending on the type of the instrument and the environment in which it is being used, it may degrade quickly or over a long period of time. The bottom line is that, calibration improves the accuracy of the measuring device.

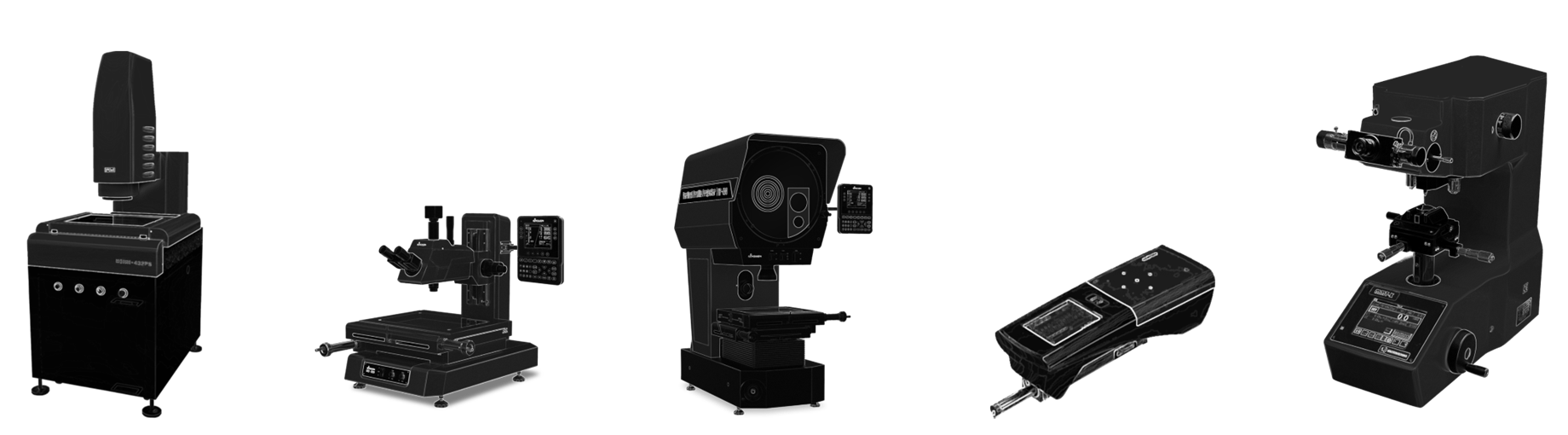

Accurate measuring device improves product quality. We utilized laser measurement system and computer aided technology, provide high accuracy, professional and competency refer to ISO/ IEC 17025 and error compensation services (for specific model).

Support for calibration of master equipment is our main service scope. Affordable price, low expanded uncertainty, fast delivery is our aiming to serve you better.

Malaysia

Malaysia