Strong performance in rugged metal housing for demanding detection tasks

The W12 photoelectric sensors can be used nearly anywhere for exact object detection in demanding environments. Whether you are working with lasers, infrared light or LEDs – the photoelectric proximity sensors, photoelectric retro-reflective sensors and through-beam photoelectric sensors are suitable for a wide range of applications. The sensors are insensitive to shocks and vibrations thanks to their zinc die cast housing. IO-Link and BluePilot allow for fast and simple parameterization. Numerous functions such as background or foreground suppression ensure extremely reliable detection of transparent or very dark objects and make the W12 resistant to interference. Condition-based maintenance based on sensor and diagnostic data reduces costs and increases efficiency.

W12 AT A GLANCE

Benefits

-Universal application possibilities thanks to MultiMode function

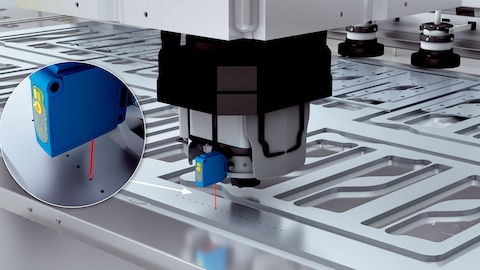

-Precise detection of small objects due to exact light spot of the laser variants

-Reliable detection of challenging objects such as very dark or sloping objects thanks to ApplicationSelect mode

-High reliability even under harsh ambient conditions thanks to tough metal housing

-Simple parameterization with BluePilot on device or via customer-friendly IO-Link user interface

-High availability levels thanks to predictive maintenance

-Reliable detection of transparent objects – from PET bottles to transparent foil – thanks to superior chip technology

Features

-Precise autocollimation optics

-Light sources: laser, PinPoint LED, infrared light

-MultiMode function

-Line-shaped light spot for detecting perforated objects

-ApplicationSelect mode available

-IO-Link and BluePilot for parameterization

-Diagnostic functions via IO-Link

-Rugged zinc die cast metal housing

ADVANTAGES

Suitable for all applications – photoelectric sensors in a metal housing

Suitable for all applications – photoelectric sensors in a metal housing

The W12 devices are genuine all-rounders. The portfolio comprises photoelectric proximity sensors, photoelectric retro-reflective sensors and through-beam photoelectric sensors with laser technology, PinPoint LED or infrared light. Different sensing ranges, switching frequencies, and connection options ensure almost limitless selection and combination possibilities. W12 sensors, for example, can be perfectly tailored to the equipment system and the requirements of the specific application – regardless of whether it be a packaging technology, automotive, logistics, pharmaceutical or beverage application.

As individual as the requirements on site: Thanks to the numerous product variants available, you can choose the ideal W12 for your needs

From glass bottles to cling film: Transparent objects can be precisely and reliable detected using the WL12G photoelectric retro-reflective sensors

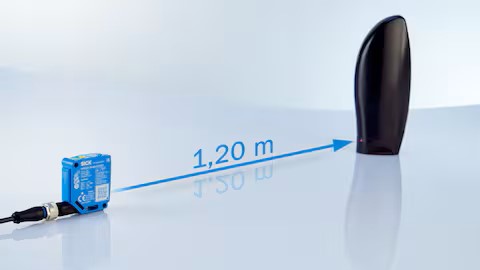

No problem with large distances: The laser variants make it possible to precisely detect very small objects over distances of up to 1,200 mm

Single device for everything: The W12 product family is the universal detection solution for a large number of industrial applications and industries

Incredibly easy – installation and commissioning using BluePilot

Incredibly easy – installation and commissioning using BluePilot

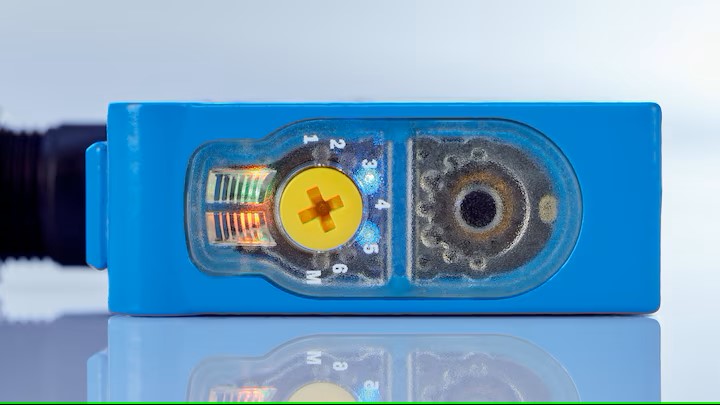

Set up and aligned in seconds: Using the BluePilot operating concept. The blue LED provides immediate feedback on whether the sensor is aligned correctly. The W12L devices with laser technology can be quickly and precisely parameterized using a Teach-Turn adjustment. While doing so, the LED display serves as an orientation aid for the desired sensing ranges or for assistance, thereby ensuring a very high operational safety. The device is especially easy to mount because the mounting holes offer different fastening options.

The LED display provides an immediate visual quality check when aligning the sensor and during installation

Fast teach-in using BluePilot

Various fastening options with through-holes and blind holes as well as elongated holes and dovetail openings

Uncomplicated mounting, fast parameterization: The W12 devices save you valuable time during commissioning

High flexibility – with just one device

High flexibility – with just one device

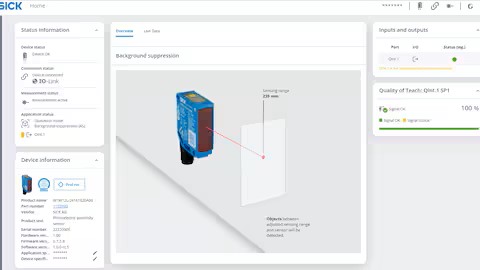

The WTM12L variants come with a MultiMode feature: Various operating modes such as background blanking, foreground blanking, two-point teach-in, two independent switching points or window teach-in can be set directly on the device or via IO-Link. It is also possible to read the distance value from the device. The advantage: The same sensor can meet a wide variety of detection requirements. This means, for example, that the settings can be adjusted with a single action when changing the product. It is no longer necessary to replace the sensor.

All of the available modes can be easily and quickly selected via the Teach-Turn adjustment

Using the “Two independent switching points” mode, standing and lying objects can be detected and distinguished from one another

Window teach-in can be used to define a window within which to perform object detection

Distance values via IO-Link: The output of precise distance values during detection extends the application possibilities of the photoelectric proximity sensors. The values can, for example, be used for positioning tasks in downstream processes

Versatile problem solver thanks to MultiMode: The W12L devices can be flexibly adjusted to changing requirements at the press of a button

Reliable detection – even at a large distance

Reliable detection – even at a large distance

In certain applications it necessary to detect objects over large distances. Using the W12L, especially large sensing ranges can be implemented thanks to the precise and powerful laser light. Furthermore, the optionally selectable ApplicationSelect operating mode provides even greater reliability when detecting dark and obliquely-oriented objects from a long distance.

The W12L laser variants are highly suitable for applications with large sensing ranges up to 1,200 mm

The focused light spot of the laser beam allows the detection of very small objects as well as precise edge recognition

The especially high sensitivity of the sensors improves the correct detection of dark and obliquely-oriented objects

Large sensing range, low error risk: The high performance laser optics of the W12L makes it possible to reliably detect even distant objects

.jpg) Everything under control – with IO-Link

Everything under control – with IO-Link

Thanks to IO-Link and comprehensive diagnostic functions, the status of the W12 photoelectric sensors can be viewed in real time. This enables faults, e.g., due to vibrations or contamination, to be detected early during operation as well as condition-based scheduling of maintenance, thereby avoiding downtimes and reducing costs.

High transparency: Production parameters can be viewed in real time via the sensor data

Reducing machine downtimes: The W12 devices detect disturbances and report these automatically

Creating needs-based service plans: Diagnostic data allow cost-efficient maintenance of sensors

Ready for Industry 4.0: Using the W12 and IO-Link, you can automate your production in diverse ways and make it especially reliable

Rugged metal housing – for very high resilience

Rugged metal housing – for very high resilience

SICK uses only zinc die cast metal housings for its W12 photoelectric sensors. This makes the sensors impervious to aggressive chemicals, high temperatures, dust, and water spray. The W12 effortlessly withstands shocks and vibrations due to machine movements or high-pressure cleaning. A high EMC resistance also protects the electronics of the sensors.

The high quality zinc die cast makes the housing especially break-proof and resilient

The chemical and thermal resistance of the housing enables it to be used under extreme ambient conditions

Thanks to a special printing method, the information on the sensor housing remains permanently readable and durable

Withstands all stresses: Thanks to the rugged metal housing, the W12 is suitable for demanding tasks in harsh environments

Reliable data – even for transparent objects

Reliable data – even for transparent objects

From PET bottles right through to transparent films – the W12G photoelectric retro-reflective sensors reliably detect highly transparent and semi-transparent objects thanks to PinPoint technology. The focused light spot has a higher light intensity and is impervious to sources of interference in the production environment. In case of contamination, the switching threshold of the sensor is automatically adjusted via an AutoAdapt function. This extends the sensor availability and lengthens the maintenance interval, thereby increasing the productivity of the system. After cleaning, the sensor automatically restores the original switching threshold.

The WL12G devices reliably detect transparent objects while keeping the operating costs low thanks to continuous threshold adaptation