Specifications

- Ambient conditions: Sunlight, contamination, standard, Moisture, water

- Beam separation: 10 mm, 5 mm, 2.5 mm, 30 mm, 25 mm, 20 mm, 50 mm

- Certificate: MAR declaration of conformity, Photobiological safety (IEC EN 62471), cULus certificate, UK declaration of conformity, China-RoHS, IO-Link, EU declaration of conformity, ACMA declaration of conformity

- Communication Interface detail: Serial (RS-485), Analog (current), EtherNet/IP, PROFINET, IO-Link (V1.1), EtherCAT, PROFIBUS DP (DPV0), CANopen, PROFIBUS DP (DPV1)

- Communication interface: Analog, IO-Link, CANopen, Serial, EtherCAT, PROFINET, EtherNet/IP, PROFIBUS DP

- Connection type: male connector M12, 5-pin, Connector M12, 12-pin, male connector M12, 8-pin, M12 female connector, 4-pin, D-coded

- Detection height: 745 mm, 2970 mm, 725 mm, 1320 mm, 575 mm, 1790 mm, 2075 mm, 1925 mm, 1000 mm, 2050 mm, 1900 mm, 2390 mm, 1625 mm, 1480 mm, 1170 mm, 2680 mm, 1300 mm, 2220 mm, 1795 mm, 1750 mm, 1600 mm, 1150 mm, 570 mm, 2975 mm, 2545 mm, 2820 mm, 870 mm, 2990 mm, 1920 mm, 440 mm, 145 mm, 590 mm, 275 mm, 890 mm, 3100 mm, 400 mm, 420 mm, 740 mm, 1025 mm, 2095 mm, 425 mm, 875 mm, 2225 mm, 2070 mm, 1645 mm, 270 mm, 2980 mm, 1495 mm, 2245 mm, 580 mm, 2380 mm, 1470 mm, 700 mm, 2525 mm, 1325 mm, 1940 mm, 2650 mm, 2080 mm, 250 mm, 1045 mm, 1640 mm, 1190 mm, 595 mm, 2690 mm, 2375 mm, 1945 mm, 2395 mm, 290 mm, 2540 mm, 880 mm, 1040 mm, 850 mm, 2950 mm, 1195 mm, 2840 mm, 1620 mm, 1775 mm, 1180 mm, 895 mm, 2200 mm, 2500 mm, 3120 mm, 1175 mm, 295 mm, 2675 mm, 1490 mm, 2370 mm, 280 mm, 1340 mm, 1345 mm, 720 mm, 1020 mm, 3125 mm, 2224 mm, 445 mm, 2800 mm, 2670 mm, 2350 mm, 550 mm, 1770 mm, 3140 mm, 1475 mm, 2520 mm, 1780 mm, 2090 mm, 140 mm, 2825 mm, 1450 mm, 2240 mm

- Device version: Pro - Advanced functionality, Prime - Standard functionality, ProNet - Replacement product (for MLG-1 with terminals), ProNet - Advanced functionality incl. fieldbus

- Housing: robust

- Length of cable: 0.27 m, 0.21 m, 0.22 m, 0.39 m, 1.4 m, 0.19 m

- Light source: LED, Infrared light

- Minimum detectable object (MDO): 29 mm, 54 mm, 9 mm, 14 mm, 2.5 mm, 10 mm, 50 mm, 4.5 mm, 30 mm, 24 mm, 25 mm, 5 mm, 20 mm, 34 mm

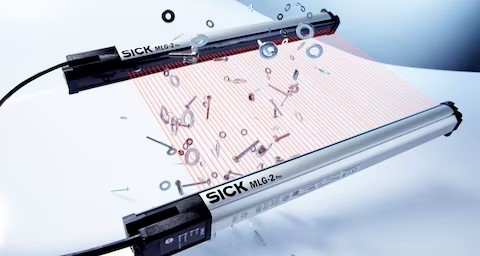

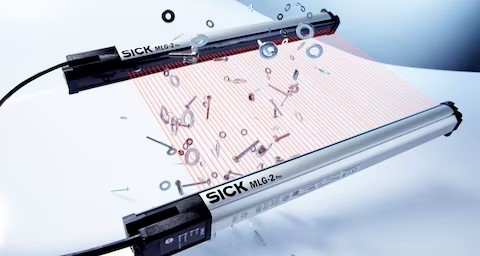

- Object properties: Detecting transparent objects, Detection of objects moving at high speeds, Detecting small objects

- Operating range: 2 m, 10.5 m, 8.5 m, 5 m, 1.5 m, 14.5 m, 3 m, 3.75 m, 6.3 m

- Option: Protective housing IP69K, none

- Preconfiguration No.: 08, 96, 97, 06, 02, 19, 14, 07, 99, 01, 33, 23, 32, 50, 04, 34, 95, 13, 03, 98, 17

- Preconfiguration: Teach (Teach input with muting), inverted (Q3), Q2 / IN (presence detection inverted), Q1 (Automatic object recognition), QA2 (height measurement (first beam)/FBB), Baud rate RS-485 (), Interface RS-485 (beam status), Q5 (off), Q2 / IN (Teach input), Teach (Automatic teach), Q3 (Auto-define height classification), inverted (Q1), In2 (off), QA1 (height measurement (first beam)/FBB), Q1 (presence detection), Q1 (Quality of run/QoR), key lock (off), Q1 (presence detection inverted), Teach (), Q2 (presence detection inverted), QA2 (Number of broken beams/NBB), Q4 / IN2 (presence detection), Address (), Teach (Standard mode), Baud rate RS-485 (125 kbit/s), Interface RS-485 (System status, virtual outputs, number of broken beams, height control (last beam)/LBB, height control (first beam)/FBB, oudside dimension, inside dimension), QA2 (height measurement (last beam)/LBB), Q3 (presence detection inverted), Q2 / IN (Auto-define height classification), QA1 (Number of broken beams/NBB), PROFIBUS DP (DPV0), PROFIBUS DP (DPV1), Baud rate RS-485 (9.6 kbit/s), Q2 / IN (presence detection), Q2 / IN (Automatic object recognition), Teach (Cross beam), In1 (Teach input), Q3 (presence detection), Q4 / IN2 (presence detection inverted), QA1 (Number of broken beams/NBB falling), Baud rate RS-485 (500 kbit/s), Q1 (Number of broken beams/NBB), Q4 / IN2 (contamination warning), Q1 (Auto-define height classification), Address (126 (SSA)), Q3 (contamination warning), Q6 (off), Interface RS-485 (System status, flow counter, RLC1 ... RLC16), Teach (Blanking, high speed mode), Q2 / IN (contamination warning), Q4 (presence detection), Interface RS-485, Address (6 (LSS)), Q1 (contamination warning), Teach (automatic teach and cross beam), Teach (Standard mode & cross beam), Q3 (Automatic object recognition), inverted ()

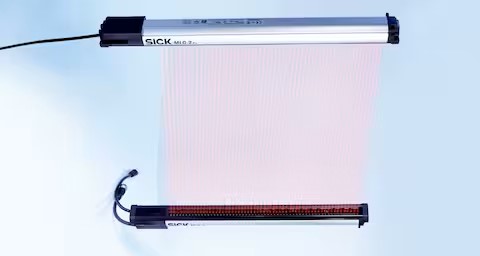

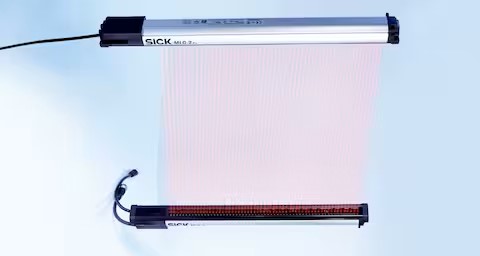

- Product family: MLG-2

- Product segment: Automation light grids

- Products by tasks: measuring, Detecting, Position determination, Protecting

- Response time: 16.3 ms, 36 ms, 6.1 ms, 44.5 ms, 12.9 ms, 7.6 ms, 10 ms, 38.5 ms, 37 ms, 7.1 ms, 24.4 ms, 6.3 ms, 7.9 ms, 19.8 ms, 33.6 ms, 4.8 ms, 40.6 ms, 7.3 ms, 21 ms, 3.5 ms, 4.4 ms, 5.9 ms, 35.5 ms, 5.7 ms, 23.3 ms, 4.3 ms, 8.5 ms, 5.5 ms, 13.8 ms, 9.6 ms, 6 ms, 10.7 ms, 5.4 ms, 8.8 ms, 38.3 ms, 15.1 ms, 41.5 ms, 19.7 ms, 12.2 ms, 15.8 ms, 14.2 ms, 47.6 ms, 4.2 ms, 22.1 ms, 9.7 ms, 8.6 ms, 9.4 ms, 12.3 ms, 3.6 ms, 29.4 ms, 6.2 ms, 27.9 ms, 4.1 ms, 6.4 ms, 8.9 ms, 18.6 ms, 24.3 ms, 10.2 ms, 9.9 ms, 7.8 ms, 25.6 ms, 53.6 ms, 7 ms, 13 ms, 11.7 ms, 18.8 ms, 21.8 ms, 11 ms, 7.2 ms, 38.2 ms, 8.2 ms, 4.6 ms, 5.2 ms, 18.5 ms, 5.6 ms, 10.9 ms, 15.2 ms, 29 ms, 12.4 ms, 11.2 ms, 17.5 ms, 11.8 ms, 26.7 ms, 17.3 ms, 7.7 ms, 6.6 ms, 24.8 ms, 26.4 ms, 9.2 ms, 6.7 ms, 50.6 ms, 5 ms, 20.3 ms, 3.8 ms, 7.5 ms, 3.7 ms, 14 ms, 9 ms, 12.7 ms, 33.7 ms, 14.8 ms, 10.5 ms, 10.6 ms, 10.1 ms, 6.9 ms, 4 ms, 3.9 ms, 6.5 ms, 13.5 ms, 8.7 ms, 32.4 ms, 31.3 ms, 33.9 ms

- Sensor principle: Sender/receiver

- Smart Sensor: Smart Task, efficient communication, Enhanced Sensing, diagnosis

- Smart Task name: base logics

- Special applications: volume measurement, Leading edge detection, Position determination, Quality check, Food & Beverage, Measures length, width and height of an object, Height monitoring, Traffic, Ejection control

- Switching outputs: push-pull: PNP/NPN

- Task: Detecting - Transparent objects, Determining position - 2D position determination, Monitoring and controlling - Quality, Detecting - Double layer, Measuring - Dimension, contour and volume, Measuring - Length and distance, Protecting objects - Infrastructure, Monitoring and controlling - Processes

- Type: MLGxxN-xxxxCx, MLGxxA-xxxxIx, MLGxxN-xxxxNx, MLGxxA-xxxxRx

Description

Flexible in use for length, width and height measurements

With the MLG-2 measuring automation light grid, SICK is offering the right solution for a wide range of applications in logistics and factory automation. The MLG-2 Prime, MLG-2 Pro and MLG-2 ProNet device variants are used in challenging applications with transparent objects and high object speeds, to name a couple of examples. With a resolution of up to 1.25 mm, the new “cross beam measurement” function and the “transparent” mode, the MLG-2 masters measuring task with high precision. The pre-installed solutions in the SOPAS ET configuration software allow even complex applications, such as object width measurement, to be parameterized with ease. The MLG-2 Pro and MLG-2 ProNet feature common industrial interfaces such as the RS845 or Ethernet interfaces.

MLG-2 AT A GLANCE

Benefits

-High measurement accuracy for detecting even very small objects reliably

-Transparent mode function for reliably detecting and measuring transparent objects

-The high-speed scan offers short response times for safely detecting objects traveling at high speeds

-The SOPAS ET configuration software with menu-driven wizard for quick configuration

-Ambient light immunity enables greater reliability

-Integrated interfaces and matching function blocks reduce the time and effort involved in the commissioning process

-Simple maintenance without the need for specialist staff thanks to the cloning function with IO-Link

Features

-Beam separation: 2.5 mm, 5 mm, 10 mm, 20 mm, 25 mm, 30 mm, 50 mm

-Maximum range: 12 m

-Functions: Cross beam measurement, 4 x zone measurement, high-speed scan, transparent mode

-Interfaces: PNP, analog, RS485, IO-Link, PROFINET, PROFIBUS, EtherCAT®, EtherNet/IPTM, CANopen

-Sun resistance mode with reliable switching threshold

MLG-2

Flexible in use for length, width and height measurements

MLG-2 measuring automation light grids from SICK offer the right solution for a wide variety of applications in logistics and factory automation. The MLG-2 units are used to monitor the material flow in conveyor belts, in automated storage and retrieval systems, in order processing and many other areas. For example, the light grid simultaneously determines the maximum height and overhang when measuring pallets. The sensors are modular and enable customers to select between different detection heights and beam separations. A clear display ensures easy configuration and diagnostics. Optical synchronization eliminates the need for wiring between the sender and receiver. SICK also offers a wide range of different types and interfaces.

Display

FlexFix bracket

Optical synchronization

The MLG-2 reliably determines the length, width and height of objects. A wide range of applications can be reliably solved thanks to the modular sensor design and the broad product portfolio.

MLG-2 PRIME

MLG-2 Prime for standard applications

The MLG-2 Prime is suitable for all standard applications, including protrusion monitoring or object height and width measurement. Connection to the control is established via push-pull switching outputs or analog outputs. Data can be output directly via the IO-Link interface and the associated function blocks. The new "object re-detection" function saves time and resources. The MLG-2 Prime can be ordered in a pre-configured version.

Determining the position of the baggage cart in the robot cell

Switching from lengthwise to transverse transport

Protrusion monitoring of pallets

The MLG-2 Prime solves your standard applications with high measurement accuracy and is quick and easy to configure.

MLG-2 PRO

MLG-2 Pro for demanding applications

The light grids of the MLG-2 Pro variant are used in demanding applications to detect transparent objects and at high object speeds. With functions such as “Transparent mode,” “High-speed scan,” or “High measurement accuracy,” the MLG-2 Pro performs challenging measuring tasks with the utmost precision. The pre-installed solutions in the SOPAS configuration software allow even complex applications to be configured with ease. The MLG-2 Pro uses conventional industrial interfaces so that even individualized solutions can be programmed via the control.

“High-speed scan” function offers short response times for safe detection at high object speeds.

The “Sun and dust” mode allows the MLG-2 to operate trouble-free, even in harsh environments.

“Transparent mode” function for reliably detecting and measuring transparent materials.

The MLG-2 Pro masters even complex tasks in demanding environments. Resistant to ambient light as well as dust and thanks to various operating modes, the light grid is ideally equipped for your tasks.

MLG-2 PRONET

MLG-2 ProNet: Easy integration

As the degree of automation of a plant or machine grows, so too does the amount of cabling required – and therefore also the work involved in planning, installation, commissioning, and maintenance. But not with the MLG-2 ProNet from SICK. It offers all the advantages of a measuring automation light grid and now features integrated interfaces such as PROFINET, EtherCAT®, EtherNet/IPTM, CANopen and PROFIBUS. Thanks to corresponding function blocks, commissioning is quick and simple. Solutions are preinstalled in the SOPAS configuration software. This allows for even complex applications, such as object width measurement, to be configured with ease. It is also possible to change the format automatically via fieldbus.

Easy parameterization via SOPAS.

PROFINET, EtherCAT®, EtherNet/IPTM, CANopen and PROFIBUS

The MLG-2 ProNet is optimally equipped for your interface: Matching function blocks reduce the time and effort involved in the commissioning process.

More detail about Truserv Technologies (M) Sdn Bhd