Measuring distances – reliable, precise and versatile

The Dx50 is a common distance sensor platform, offering multiple performance levels. With measurement ranges of up to 10 m or 20 m on objects or even up to 50 m when measuring on reflector, the Dx50 is suitable for many different applications. Based on a switching, analog or serial interface being available the Dx50 can easily be integrated in any application environment. Also the intuitive operating concept and a visible red laser allow a fast installation of the sensors. Thanks to the innovative HDDM technology the Dx50 provides excellent reliability, immunity to ambient light and precision when being in use. Offering an extremely good price/performance ratio the Dx50 is the right solution in many cases.

Dx50 AT A GLANCE

Benefits

-Wide measurement ranges up to 10, 20 or 50 m in combination with different interfaces allow an easy and fast integration in any production environment

-Highly reliable and precise measurement helps to increase process quality and stability

-High measurement or switching frequencies enable a fast material flow

-Dx50 product family is based on a common platform, offering multiple performance levels, making it easy to accommodate future changes

-Intuitive setup via display or remote teach reduces installation time and costs

-Temperature range from –30 °C to +65 °C allows for outdoor use without additional cooling or heating

-Up to 40 klx ambient light immunity – allows for use in optically challenging environments

Features

-Highest reliability, ambient light immunity and price/performance ratio thanks to HDDM technology

-Measuring ranges of 10 m or 20 m directly on the object or 50 m on the reflector

-Different performance levels depending on the product and laser class

-Various interfaces: Digital, analog or serial

-Display with intuitive and consistent operating concept

-Rugged zinc die cast housing

-Wide operating temperature range from –30 °C to +65 °C

ADVANTAGES

The Dx50 product family sets standards thanks to the HDDM technology

The Dx50 product family sets standards thanks to the HDDM technology

With the Dx50 product family, SICK has for the first time designed distance sensors which differ significantly from comparable products thanks to their slim design and impressive measurement performance. The generously dimensioned optical unit of the Dx50 allows for distance measurements with a scanning range of up to 50 m, both indoors and outdoors. The extensive product range of the sensor interfaces enables seamless implementation into the customer application. Commissioning is simple thanks to the self-explanatory user interface. The Dx50 is also characterized by an attractive price-performance ratio.

Outstanding ambient light immunity

Dx50 distance sensors are resistant to ambient light and ensure interference-free operation and reliable definition of distances both in- and outdoors.

HDDM technology

The unique HDDM technology from SICK is a milestone in the development of distance sensor technology. In doing so, the sensor uses the runtime of several laser pulses from the sensor in the direction of the measuring object and back to calculate the distance between the two. This enables stable and gap-free scanning as well as reliable measurement results. And all of this even in dirty, dusty and moist environments.

Wide range of variants

Dx50 distance sensors from SICK can be easily integrated into new and existing machines and systems. Whether as a scanning or reflector-based variant, with laser class 1 or 2, with analog, digital or serial interface, the combinations are nearly endless. Should you want a sensor with customized configuration in addition to all this, SICK is happy to do it.

Discover here what sets the Dx50 distance sensor apart.

Impressive measuring range

With scanning ranges of up to 50 m, the Dx50 offers a wide range of applications.

Remarkable ambient temperature range

The ambient temperature range from –30 °C to 140 °C makes it possible to use the sensor worldwide without restriction – both in- and outdoors and even in deep-freeze applications.

The compact sensor has a very large ambient temperature range. The Dx50 is resistant to ambient light and the right sensor is available for nearly any application due to its large range of variants.

Thanks to its flexibility, reliability and balanced price-performance ratio, the Dx50 product family is suitable for countless applications across all sectors.

Thanks to its flexibility, reliability and balanced price-performance ratio, the Dx50 product family is suitable for countless applications across all sectors.

Vertical positioning of cranes in warehouses

For smaller components, vertical cranes are used in the subsequent production areas of rolling mills. These are used to move small parts into automated high-bay racking. To ensure that the correct rack positions are approached, a mid range distance sensor supports crane positioning. The compact DL50 Hi offers excellent performance values up to 50 m. The HDDM technology used impresses due to the reliability and impressive repeatability. The red laser light enables precise alignment. The stable metal housing is well-suited for the harsh ambient conditions in the storage areas of rolling mills.

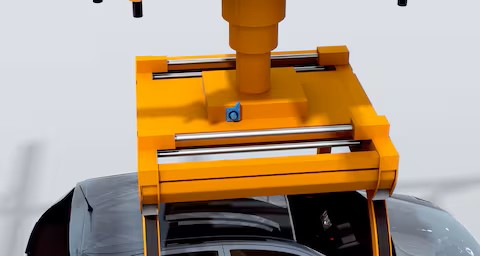

Vertical positioning in electrical overhead conveyors

The electrical overhead conveyor brings car bodies, engines and other components which are difficult to transport into defined workstations. With its excellent repeatability, the DL50 Hi is well-suited for this important task and ensures that the height position is approached exactly.

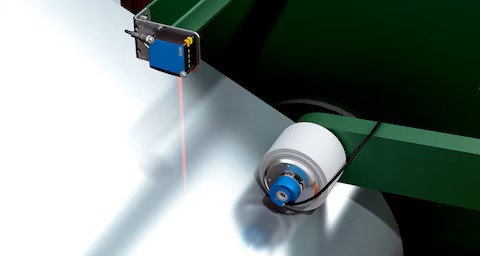

Diameter monitoring during coil winding processes

When the steel strip manufacturing process is complete, the high-quality strips are wound into coils. Precise diameter monitoring is required here so the right length can be detected at all times. The DT50 distance sensor supports this important process step with precision down to the last millimeter.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.