The fast way to high-performance 3D

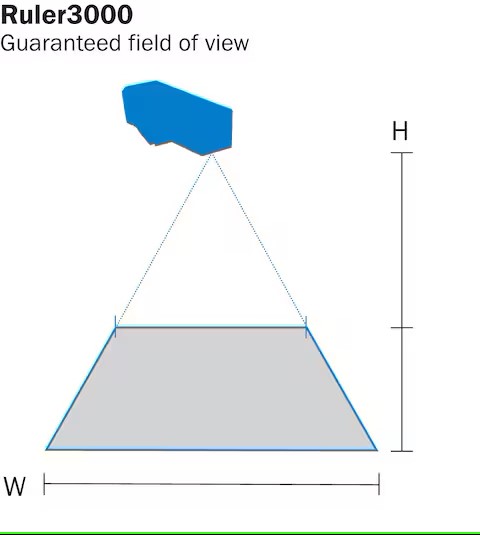

Highly accurate with an unmatched measurement speed, the new generation Ruler3000 3D cameras will be the number one choice for machine vision system integrators and industrial applications. Being powered by the unique 3D CMOS sensor from SICK tailored for superior image processing, their measurement results are very reliable. The factory-calibrated sensor extracts the true 3D shape of an object, regardless of its contrast or color. The numerous versions of Ruler3000 offer a solution for a wide range of challenges and can deliver accurate measurement values down to 0.8 µm in height with a resolution of 3200 data points per profile. Thanks to the guaranteed field-of-view concept, commissioning is easy. GigE Vision and GenICam compliance ensures cost-effective integration.

Ruler3000 AT A GLANCE

Benefits

-Factory calibration shortens integration time

-The unique CMOS sensor enables fast 3D measurement speed for increased throughput

-Guaranteed field of view simplifies commissioning

-Suitable for batch size one and flexible production thanks to reliable and accurate measurements on dark and shiny surfaces

-High light sensitivity for 3D inspection with laser class 2 and 3R

-Standardized and cost-effective software integration with GigE Vision and GenICam

-Scalability by sharing software and feature set with Ranger3 3D vision cameras

Features

-SICK’s CMOS sensor with ROCC technology for superior 3D performance

-3D profiles at up to 46 kHz in reduced ROI

-Easy commissioning with guaranteed FOV concept

-GigE Vision and GenICam compliant

-Accurate 3D, reflectance, and scattered light measurements in one device

-Modular industrial design, IP65/67

ADVANTAGES

.jpg) High-tech 3D machine vision made easy

High-tech 3D machine vision made easy

The new 3D vision solution from SICK, Ruler3000, fits a wide variety of industrial needs. It is fast and offers high image quality. The 3D camera, built around the same CMOS sensor from SICK as the Ranger3 product family, offers superior image processing and reliable measurement results. Ruler3000 is easy to integrate and use. Its design is compact and the factory-calibrated camera has all the convenience features needed, including specific geometries for predefined fields of view.

https://youtu.be/FeTZYjOvhRM

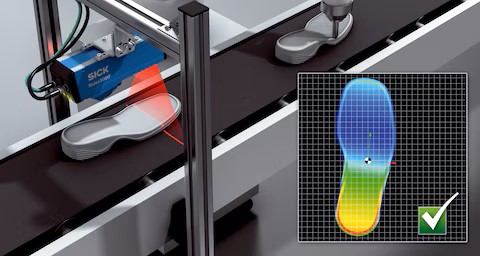

Highly accurate and reliable 3D measurements in FoV, width from 27 mm up to 1.7 m.

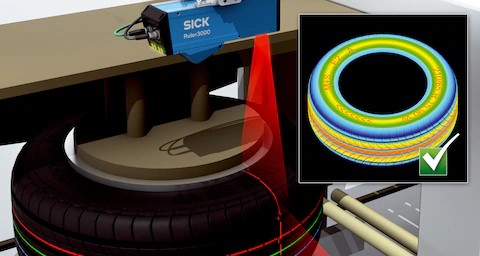

The high light sensitivity of Ruler3000 ensures accurate inspection even of very dark materials. Ruler3020 in particular has a field of view that is ideal for tire side wall applications.

Ruler3000 can deliver millimeter-precise data as input to the robot, quickly and accurately guiding it through any dispensing application.

The new Ruler3000 3D camera from SICK is the perfect fit for a wide variety of applications in factory automation.

Keep it simple

The Ruler3000 3D camera offers ease of use and simplified integration into systems and machines using industry standards such as GigEVision and GenICam as well as SICK’s own API GenIStream. In every aspect, simplicity is a given: A suitable lens and laser are already designed into the sensor and software is provided for easy setup.

Ruler3000 comes factory-calibrated with a suitable laser and optics in a rugged housing. You can start the measuring directly.

Thanks to the guaranteed field-of-view concept, commissioning is easy. You can quickly move from the lab to the factory floor.

The included software components, Stream Setup and the API GenIStream, are especially designed with simplicity in mind.

Ruler3000 enables you to easily solve complex inspection and measurement tasks.

Captures even very small object details with measurements in the micrometer range

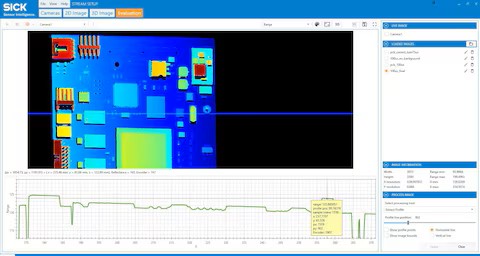

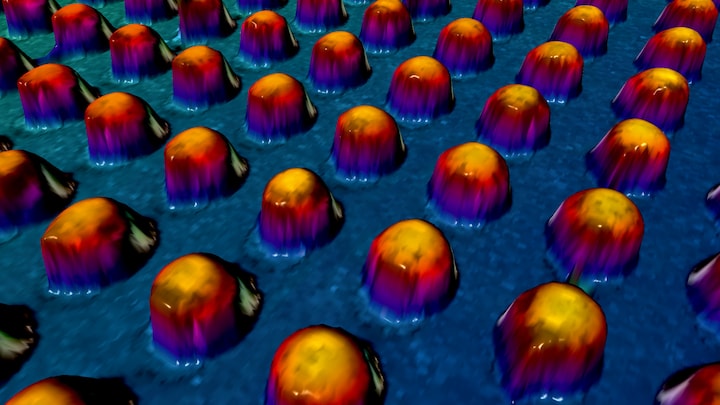

Part of the Ruler3000 family is tailored to the electronics and semiconductor industries and is focused on capturing the really small details with micrometer measurements. Thanks to options for different fields of view, and blue or red lasers in laser class 2 or 3R, there are solutions for reliable results with challenging materials.

With accurate measurements down to 0.8 μm in height, even minuscule details are captured with accuracy.

Ruler3000 has options for a blue 3R laser, which enables high-speed applications as well as better image quality on shiny surfaces.

Get high-quality data even for complex applications

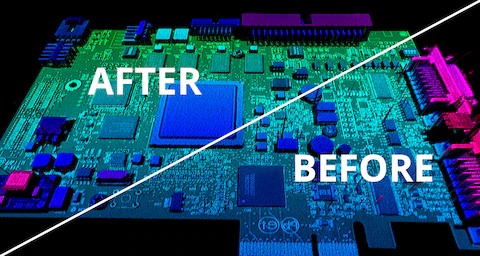

The dual-exposure feature increases the image quality in high-contrast scenes with large variations in surface reflectivity, such as very dark and very shiny surfaces in the same scene. This means good image quality both on highly reflective, shiny surfaces as well as on surfaces with high contrast variation.

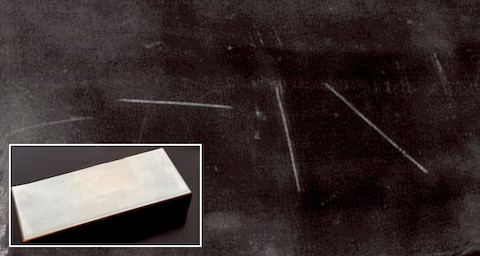

Surface+ is a new, patent pending technology that provides an additional image dimension revealing even the tiniest scratch on a smooth surface. It can also be used for measuring the glossiness of surfaces to detect paint or coating defects, for example.

The Stream Setup configuration software provides user-friendly tools for noise reduction and false data removal.

The Ruler3000 offers solutions for reliable results with demanding materials

Setting a new standard for high-speed 3D

With ever-increasing needs for faster manufacturing processes, more accurate quality control, and shorter delivery times, each part must keep up to the speed with the others. The new 3D streaming cameras from SICK not only keep up, they exceed the pace – creating new opportunities in the area of machine vision for machine builders and system integrators in a wide range of industrial applications.

.jpg)

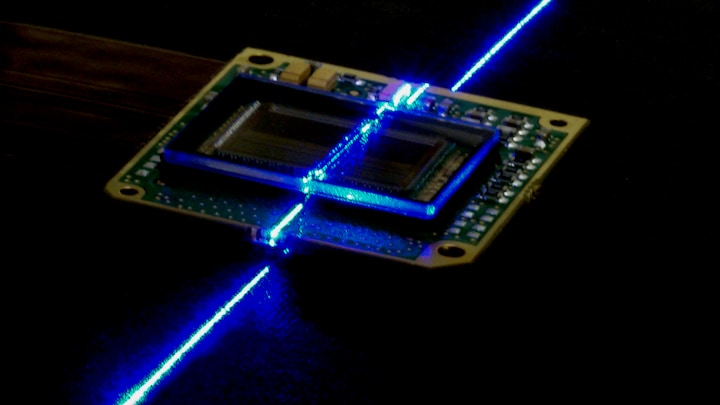

SICK CMOS 3D sensor.

Faster and more precise shape, volume, and position measurements with 3D cameras from SICK.

.jpg)

Superior 3D performance with Rapid On-Chip Calculation technology (ROCC).

Highly accurate with an unmatched measurement speed, the new generation of 3D cameras support machine vision system integrators worldwide.

SIM2x00 Nova 3D – The fast and easy way to high-performance 3D

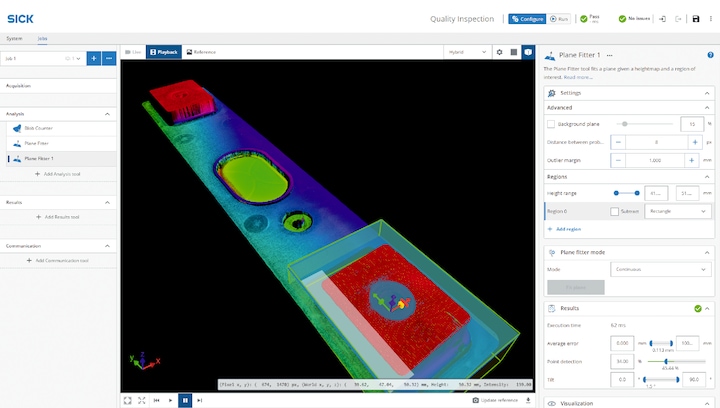

The combination of Ruler3000 3D camera connected to SIM2x00 Sensor Integration Machine running SICK Nova enables an easy-to-use solution. The Ruler3000 provides superior 3D data at high speed for detailed quality assurance

The user-friendly web interface with point-and-click configuration provides an intuitive 2D and 3D viewer, making the configuration quick and easy to use – even by non-experts.

Go one step further with SICK Nova

Machine vision applications are easily handled in a web browser using point-and-click configuration, giving users the freedom to combine tools for image processing and integration as they need. But the functionality does not end there: With SICK Nova, users can download additional Nova tools or develop their own, allowing them to quickly and conveniently extend functionality to fit the application — without limitations.

https://youtu.be/9dk3b6dBXlw

Quickly solve tasks with just the right tools at your fingertips

Choose the right sensor for the application and use the same familiar software.

.jpg)

Rapidly create customized solutions with AppPool downloads or custom development.

Rapidly handle your applications like never before. Add, combine, and customize tools with ease.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.