Features :

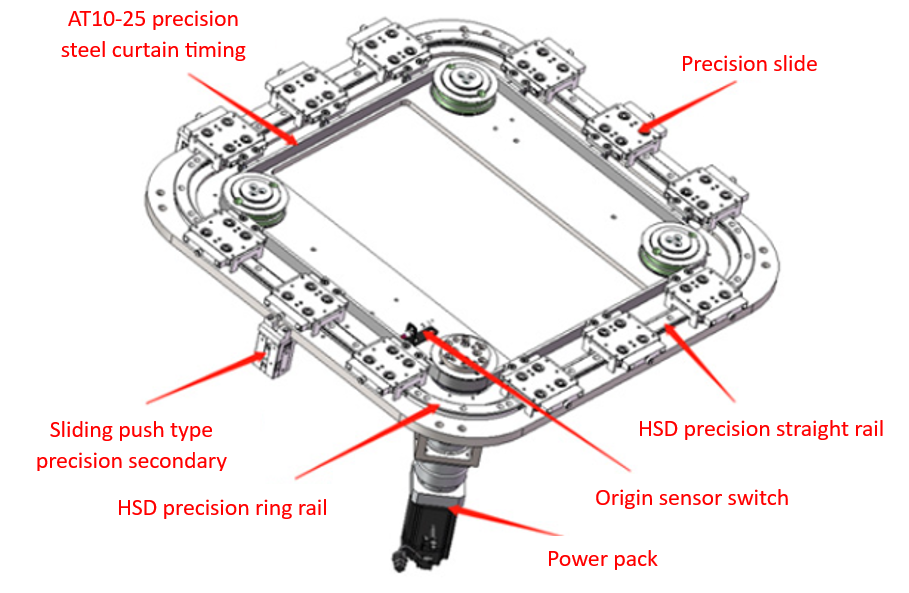

High Precision and Speed: This line integrates HSD’s proprietary V-type track and GMP series components for high precision, rapid speed, and low noise operation.

Efficient Installation: Using the bottom plate as the installation reference, the line can extend over 10 meters, making installation quick and easy.

Robust and Durable Synchronous Belt System: Equipped with Huiside's AT10 steel-reinforced synchronous belts in 25mm or 50mm widths; for lines exceeding 8 meters or heavier loads, a 50mm width or thicker belt is recommended. The steel-reinforced belt offers strong tensile resistance, durability, excellent synchronization, and precision.

Flexible Positioning: Features a secondary sliding positioning mechanism with repeat positioning accuracy within ±0.05mm. This mechanism can be mounted on the inside or outside of the line body, with this model showcasing outer positioning.

Reliable and Stable Motor Control: The system includes servo motors and helical planetary reducers, delivering stable, reliable torque and easy control.

Ideal for Complex, Multi-Station Projects: Designed to support projects with multiple workstations and intricate processes, meeting the demands of complex workflows.

Easy Installation and Adjustment: Enables precise setup and debugging.

Optimized for Spacious Environments: Rectangular design with multiple precision workstations provides ample internal space, allowing for flexible equipment installation inside and out.

High Performance: Operates quietly with high speed and precision.

Durable Steel Curtain Belts: Overcomes common belt weaknesses with a steel curtain design that prevents breakage and damage.

Precise Sliding Positioning: Sliding push mechanism ensures consistent repeat positioning accuracy.

Efficient and Stable Machine Structure: Sliding push positioning offers easy installation, efficiency, machine integrity, and high stability.

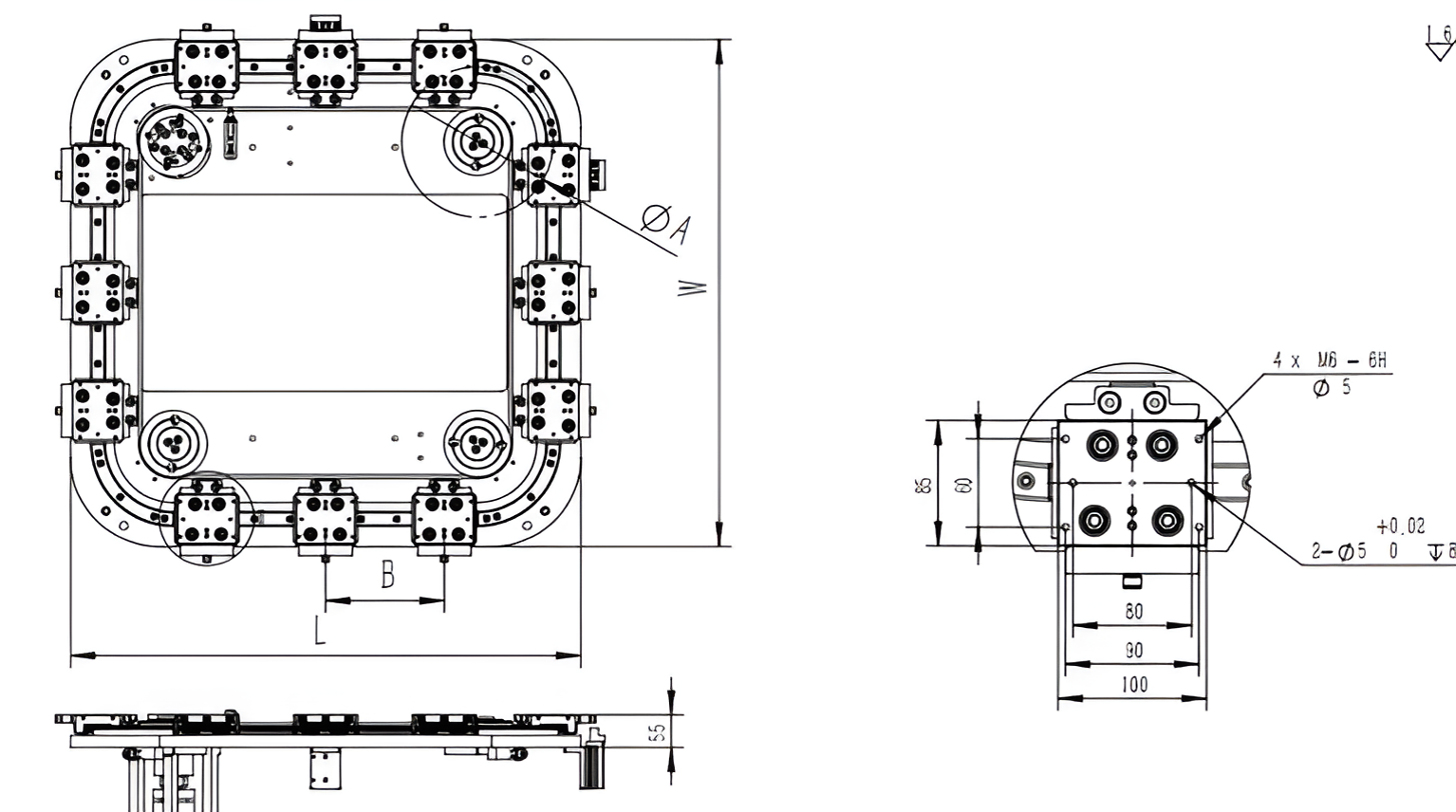

Applicable Ring Rail Sizes: Compatible with ring rails φ255, φ300, φ351, φ400, φ468, φ500, φ600.

| Product Name | Rectangular bottom belt - push and slide positioning |

| Product Model | LOP-RE1-L255-12/2T-S200-SPP-HPH |

| Overall dimensions | 860*860*212MM |

| Overall structure | Base plate |

| Transmission mode | Steel curtain synchronous belt |

| Installation method | Horizontal |

| Positioning method | Outside sliding push |

| Ring rail size | 4255 |

| Slide distance | 200mm |

| Slide number/precision station | 12/2T |

| Cutting speed | 1.0S |

| Single slide bearing | 5-15kg |

Malaysia

Malaysia