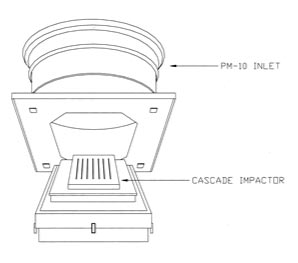

The new high volume Air Flow PM10-HVS sampler line equipment perfectly complies with UNI-EN 12341 norm requirements for the respective sampling of PM-10 particles. It is equipped with an electronic flow control with a Venturi tube system in compliant with ISO 5167 requirements with differential pressure devices and for the detection of pressure itself on 4 points per sector, offering the user maximised accuracy for reliable results. The new PM 10 dust particle impactor splitting were constructed in full compliance with requirements published in reference methods. When used with the aid of simple adapter kits, they can be replaced between one sampler and another for simple, versatile use. All sampling phase settings are electronically programmed. Samplings can be set by time, volume, cyclical sampling, from quadrant sector sampling. All detected data are stored in the memory and transferred to a PC or to an optional local printer with RS and USB ports, with the possibility of remote GSM/GPRS control (optional). Thanks to new electronic support, it is possible to view all reported data at set values, sampling levels exceeding flow control chart patterns to ensure proper sampling development.AirFlow HVS-PM10 High Volume Sampler

Sampler for environmental parameters

.png)

- Set sampling time

- Remaining sampling time

- Atmospheric temperature

- Cabin temperature

- Atmospheric barometric pressure

- Sampling flow rate

- Sampling volume

- Standardized sampling volume

- Sampling irregularities

- Wind speed (with installed sensor)

- Wind direction (with installed sensor)

- Sampling summary data (max. 25 tests)

It is also possible to store in the memory a series of sampling settings related to standard or further monitored sites. High resolution Atmospheric Pressure, Atmospheric Temperature, Sampling Flow Rate and Standard Deviation on sampling flow graphics can also be viewed on the display.

This option offers a further guarantee if compared to other samplers which have not been mentioned in reference.

This distribution by differentiation of the aerodynamic diameter, different from the aerodynamic geometry, able to identify the type of trajectory which particles take inside the suction flow related to the three main aerodynamic factors of the particles themselves: dimension, shape and density. Three available models for use with 1.27m3 per minute suction flow are: 4 stages, 5 stages and single stage for PM-2.5 particles. The impactors are constructed in anodised aluminium able to stand up to the most severe atmospheric conditions. A Teflon coated version is also available upon request. Impactors from 2 to 5 are arranged with 10 parallel slits. Impactor 1 has 9 slits. The impactor is mounted directly on the upper part of the 20x25 filter holder and the membranes are made in fibreglass to facilitate particle retention. Different particle size fractions can be sampled modifying the sampling flow, reducing by 50% and using the same inertial impact supports.

The following chart illustrates the various divisible particle size fractions.

.png)

Technical Specifications

.png)

Order Information:.png)

Malaysia

Malaysia