ATW200 is a differential fiber-optic displacement sensor! With our unique arrangement of optic fibers (patent granted), nanometer-order resolution and responsiveness of 3 MHz are achieved, and influence by reflectance of the measured target is suppressed.

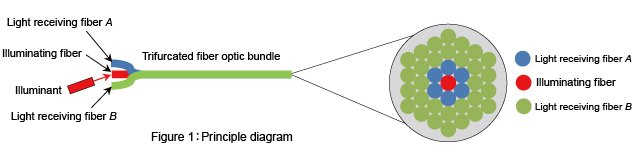

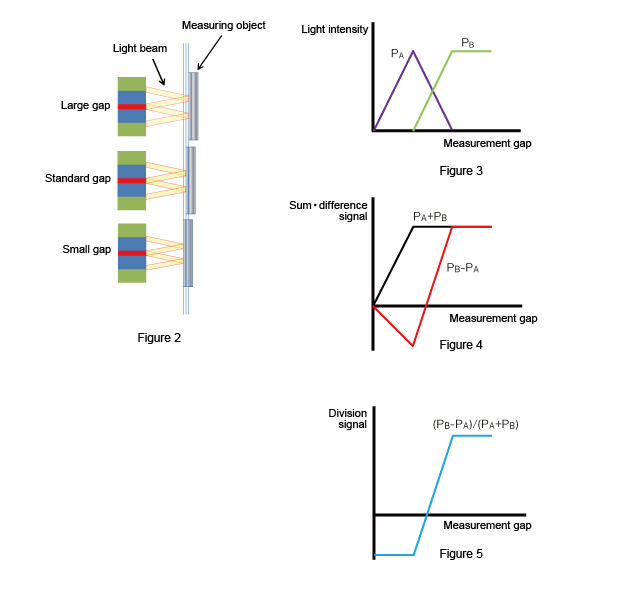

As shown in Figure 1, fiber optic bundle is splitted into 3 branches, each connecting to the opposite side of the illuminating fiber, light receiving fiber A and light receiving fiber B placed at the measurement terminal. When the light from light source is projected diagonally onto the illuminating fiber, the light will be reflected from the suface of measuring object as shown in Figure 2 onto the light receiving fiber. At that moment, the reflected light will form a ring shape, and its diameter varies according to the measurement gap. The amount of light projected onto the light receiving fiber is labeled as PA and PB, and the changes are shown in Figure 3. In Figure 4, the sum of signal PA+PB is the total light reflected, whereas the difference between signal PB-PA changes according to the gap. The signal obtained through division of the difference and sum signals is irrelevant to the reflectance of the measuring object. (Figure 5)

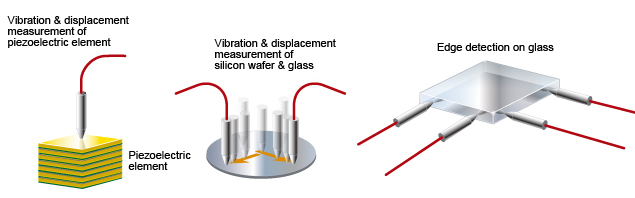

Ideal for the high-speed micro-displacement measurement (e.g. scanning probe microscope cantilever, piezoelectric elements, LCD glass, vibration analysis of glass disk, etc…).

Amplification unit|Plug-in module|Resolution example

| Amplification unit | |

| Model | ATW200 |

|---|---|

| Principle | Differential fiber-optic type |

|

Responsivity(Hz) Available response frequency |

100, 1K, 10K, 100K, 1M, PASS (3M) |

| Variable magnification |

×1, ×2, ×5, ×10,×20, ×50 |

| Display | 4 and 1/2 digit digital voltage meter |

| Analog output | ±10V |

| Operating voltage | AC 100V 50/60Hz or DC24V 1.2A |

| Operating conditions | 0 to 45℃ 20 to 85%RH (non-condensation) |

| Plug-in module | |||

| Module No. | ATP201 | ATP202 | ATP203 |

|---|---|---|---|

| Illuminant | SLD (super luminescent diode)(λ=830nm) | ||

| Fiber length | 1m (standard) | ||

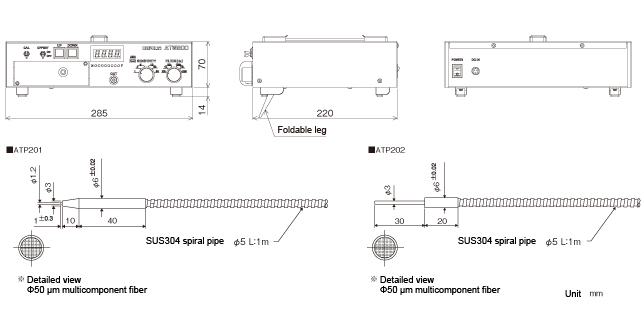

| Outer diameter of probe tip (mmφ) | 1.2 | 3.0 | 1.2 |

| Operating temperature range of probe tip* | 0~150℃ | 0~70℃ | 0~150℃ |

| Measuring spot diameter (mmφ) | Approx. 0.3 | Approx. 1.5 | Approx. 0.3 |

| Measurement range (μm) | Approx. 20 | Approx. 300 | Approx. 12 |

| Operating range (μm) | Approx. 80 | Approx. 700 | Approx. 50 |

| Sensitivity (μm/V) | Approx. 2 | Approx. 30 | Approx. 1.3 |

| * It is the temperature range that the probe can tolerate, but the accuracy is not guaranteed. | |||

| Resolution example (If the measuring object is a block gauge) | |||

| Cutoff frequency | ATP201 Resolution (nmrms) | ATP202 Resolution (nmrms) | ATP203 Resolution (nmrms) |

|---|---|---|---|

| 3MHz | 12nm | 1.2μm | 2.5nm |

| 1MHz | 7nm | 1μm | 2.3nm |

| 100kHz | 1.6nm | 0.3μm | 1.0nm |

| 10kHz | 0.7nm | 0.2μm | 0.5nm |

| 1kHz | 0.6nm | 0.2μm | 0.4nm |

| 100Hz | 0.5nm | 0.2μm | 0.3nm |

| Resolution will change according to the reflectance of measuring object. | |||

● We can also custom-made the fiber probe (e.g. extension in length, bent-tip type, etc…).Please contact us if you need that.

● The above characteristics are typical values.A difference may occur because of the variability in the sensor probe production.

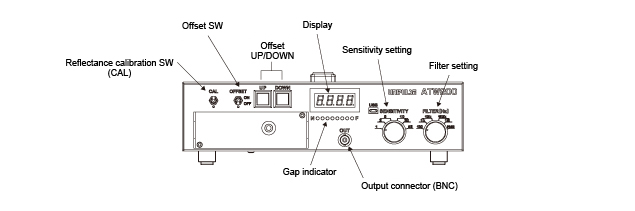

Hold the probe closer to the measuring object and turn ON the reflectance calibration SW. Numerical values will disappear from the display as it enters calibration mode. Follow the instructions from the display and adjust the measurement gap to the specified range. When calibration is completed, the ATW200 will return to measuring mode and the numerical value will be displayed.

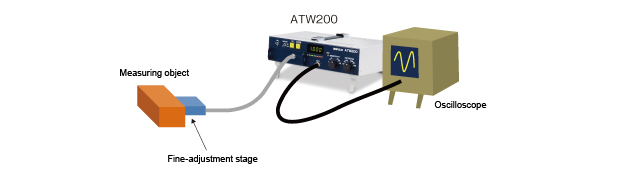

Hold the probe closer to the measuring object. It is recommended to attach fine-adjustment stage to enable slight movement.

Malaysia

Malaysia