Application

Reliable level measurement of crude and bulk liquids storage tanks in a refinery is necessary for inventory management and overspill protection. Multiple measurement devices can fit into a single process fitting.

Your benefit

Reliable

Redundant measurement ensures a high degree of safety

Cost effective

Self-monitoring reduces maintenance costs

User friendly

Easy installation and setup

Recommended products

VEGASWING 63

Vibrating level switch for overfill protection in finished product tanks

- High level switch provides redundancy

- Maximum flexibility through switching point adaptable to the application

- By simply pushing a button, you can meet the requirements of WHG and SIL of the periodic test

- Unaffected by media properties ensures reliable measurement

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

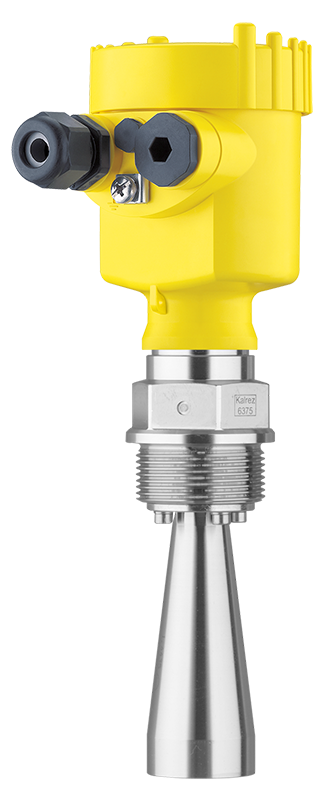

VEGAPULS 62

Level measurement with radar in finished product tanks

- Simple retrofit capability utilizes existing process fittings

- Exact measuring results independent of temperature, gas or steam

- Use of optional PLV (Positive Level Verification) system fulfils API 2350 requirements

Measuring range - Distance

Malaysia

Malaysia