Application

Accurate level control of the depropanizer ensures product quality of the obtained hydrocarbons, but this is made difficult due to hot liquids flashing, buildup and high temperature. Even through quick process changes reliable level measurement and point level detection are required to ensure a smooth operation of the plant.

Your benefit

Reliable

Overfill protection increases plant safety

Cost effective

Low maintenance costs, because non-moving parts

User friendly

Unaffected by process conditions

Recommended products

VEGAFLEX 86

Level measurement with guided wave radar in the depropanizer

-

Non-moving parts are immune to mechanical failure

-

Low maintenance requirements reduce downtime and costs

-

Certain measurement even by changing process conditions

Measuring range - Distance

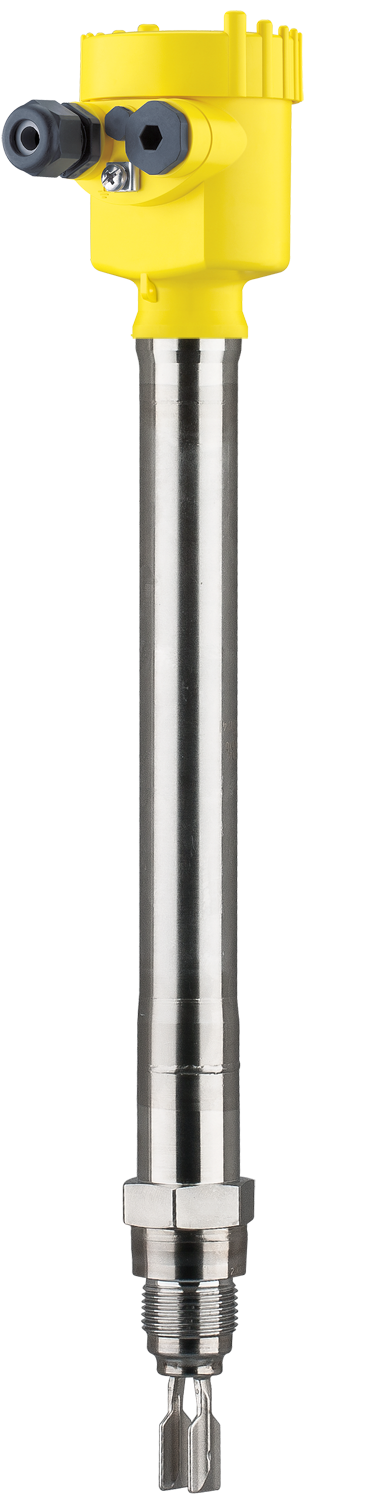

VEGASWING 66

Vibrating level switch for monitoring high and low alarm in the depropanizer

-

Reliable measurement unaffected by high temperature and pressure

-

Test function during operation provides higher plant availability

-

Redundancy increases plant safety and availability

Version

Compact version

with gas-tight leadthrough

with tube extension

Malaysia

Malaysia