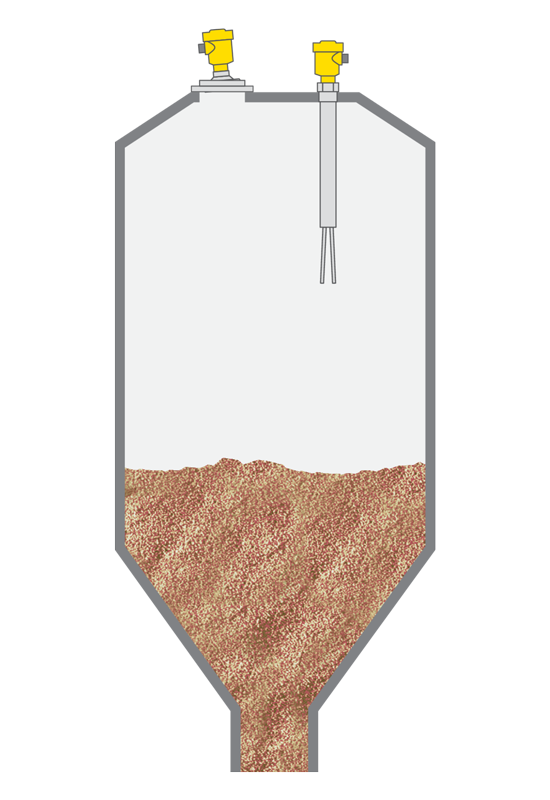

Application

Before being burned in the rotary kiln, the material from the blending bed and the aggregates are ground to a fine raw meal in large mills. The powdery material is then transported to the silo by a pneumatic conveyor system. Reliable monitoring of the level is essential for optimal raw material storage.

Your benefit

Reliable

Reliable measurement ensures a continuous supply of raw material

Cost effective

Optimal stocks ensure continuous production

User friendly

Maintenance-free operation

Recommended products

VEGAPULS 69

Level measurement with radar in raw meal silos

-

Reliable measurement, unaffected by dust and buildup

-

Maintenance-free operation thanks to encapsulated antenna system

-

High plant availability, because wear and maintenance-free

Measuring range - Distance

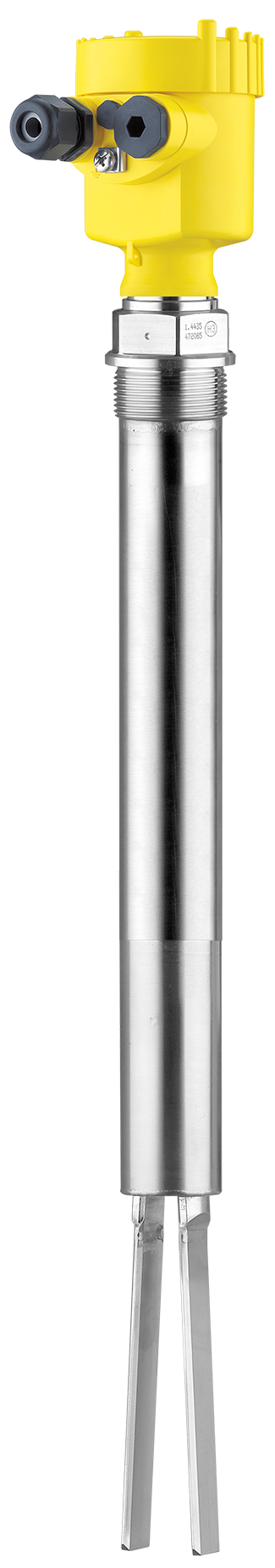

VEGAWAVE 63

Vibrating level switch as overfill protection in raw meal silos

-

Reliable product-independent switching point

-

Long service life thanks to robust sensor construction

-

Simple setup without adjustment

Version

Detection of solids in water

with tube extension

with temperature adapter

Malaysia

Malaysia