The newly-developed powder management center is an efficient and space-saving solution for automatic powder coating line,

has the following highlights:

- Allows directly placing the original powder package into the bottom funnel, much more flexible for color change.

- Automatic cleaning of hopper, suction tube, injectors, pump, hoses and spray guns, maximize efficiency during color change.

- Closed powder circuit prevents overflow to ensures a clean working environment as well as save powders.

- Has a very compact design and can be flexibly adapted to any system layout.

COLO-PP05 Powder Pump

- The feeding from original powder box to system is based on the proven COLO-PP05 powder pumps.

- The pump convey the powder gently to the powder hopper

- Without any moving parts and therefore require minimum maintenance.

Ultrasonic sieve insert:

– Sieving of recycled powder and fresh feeding powder

– Free-swinging sieve surface requires less energy and maximize sieving performance

– Different mesh sizes available

– Extremely gentle sieving

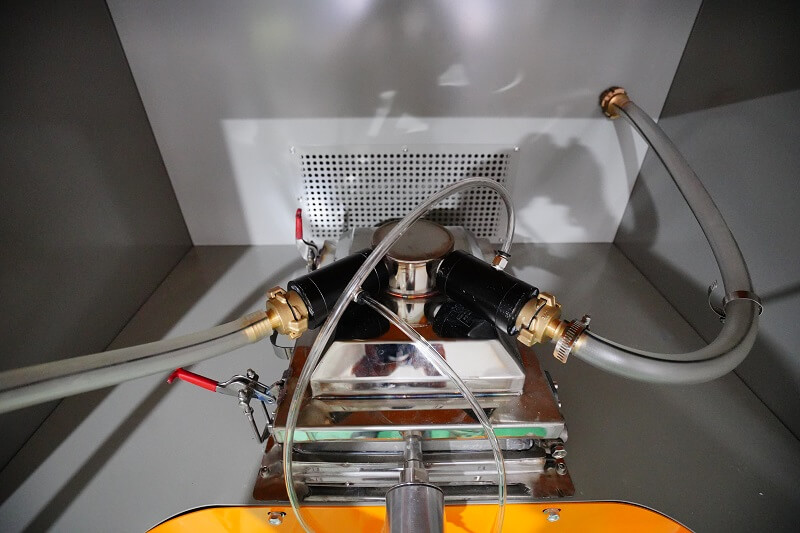

Powder Hopper

- Fresh powders and recovery powders are sieved to the powder hopper with optimal fluidization condition.

- With detection of the powder level that shows at display, guarantee a constantly available powder quantity.

- Closed powder hopper avoids powder escaping and ensure clean working environment,

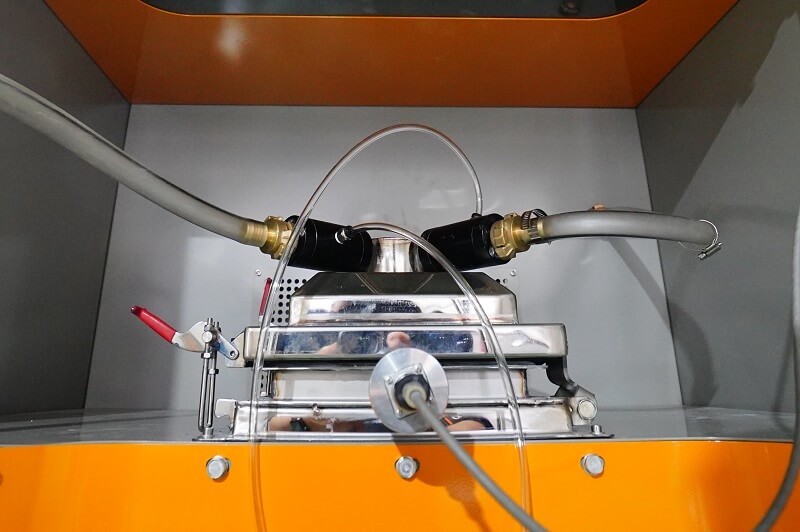

Powder Injector Arrangement

- The integrated injector technology is characterized by longevity and stable application results.

- All the powder injectors are horizontally integrated with extremely compact arrangement.

Integrated Control PLC System

- PLC system with touch screen is particularly intuitive that integrates all functions you need.

- Control every component of powder coating line, such as powder feeding, powder recovery, powder booth cleaning, reciprocating, fan working and curing time, etc

- Extremely easier operation of the coating and color change process

| Power supply : | AC 220V/110V 50Hz-60Hz (as required) |

| Nominal frequency: | 38kHz |

| Powder hopper size: | 310*240*270mm |

| Sieve frame size: | 345*275*30mm |

| Standard mesh size: | 80 mesh (on request) |

| Mesh size: | 3-4kgs/min (depending on type of powder) |

| Power consumption: | max 100W |

| Ambient: | 5-40 ℃ |