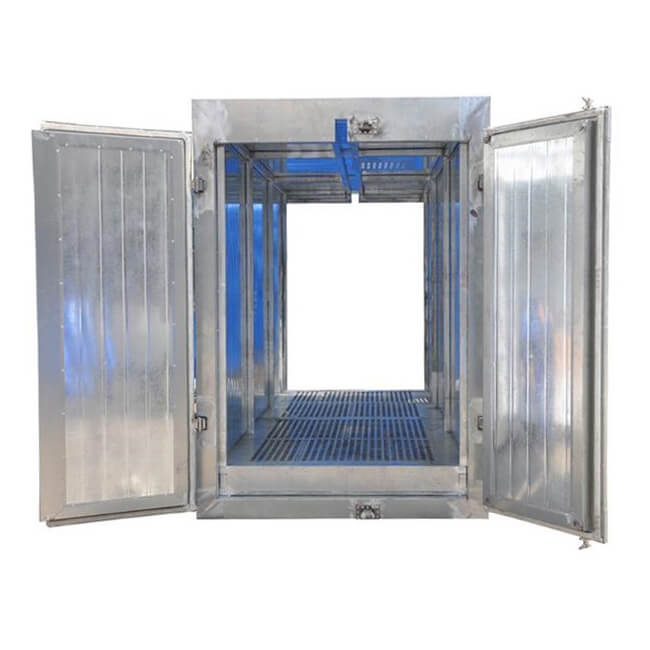

For this kind of powder coating ovens, top track is installed with conveyor in order to carry material into the oven, especially it is suitable for the heavy materials. With double-opened doors, this oven allows to cure parts continuously by loading them from one side and removing coated ones from another.

Rock Wool Insulation Board 100mm

Rock Wool Insulation Board 100mm

The powder coating oven insulation material is 100mm thickness rock wool board, which always maintain the warmness in the oven chamber. The inner wall is 1mm galvanized steel which is heat-resistant, while the outerwall is durable color steel sheet.

PLC Control System

PLC Control System

PLC Control provides high precision heating process, it offers all the features you need. The panel allows you to set the accurate temperature and duration you require, as well as control the working of fan.

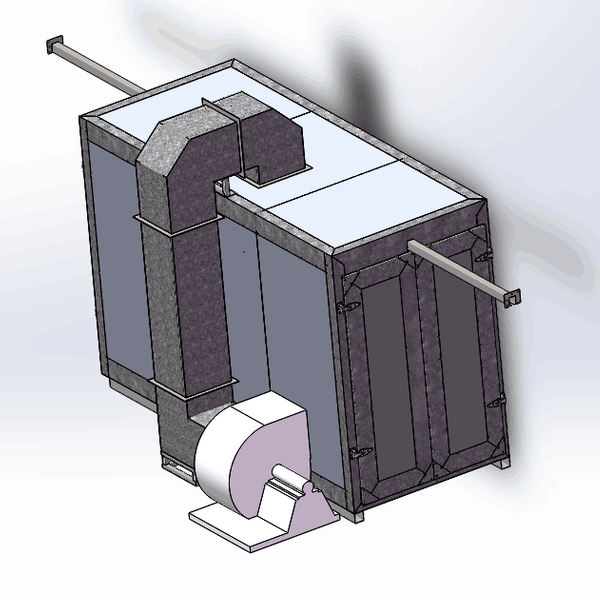

Circulation Fan

Circulation Fan

We can boast a very good temperature uniformity result due to the circulation fan. Our research has shown the temperature stability does not exceed ±5°C. The optimal airflow throughout the powder coating oven enclosure creates an even, constant cure for your parts..

| Model | Colo-2447 |

|---|---|

| Worksize dimensions | 1200width x 1700 height x 3200 depth |

| Overall dimensions | 1400 width x 2200 height x 3400 depth |

| Power supply | Electric/ 40kw |

| Voltage/Frequency | 380V/220v(50-60hz) |

| Warm-up time | 15-30 min. (180° C) |

| Temperature stability | < ± 3-5°C |

| Temperature max. | 250° C |

| Ventilation performance | 805-1677m3/h |

| Motor power | 2.2kw |

| Circulation/ Air flow | Vertical ,Variable through holes on the walls |

| Transportation | Top conveyor |

| Warranty | 12 months |

We can customize different sizes of track powder coating ovens for you, and can be made by electric, gas or diesel heating, the quantity of to track can be also designed.

1. Our powder coating ovens are designed specially for powder coating, no pollution for parts and environment.

2. We use advanced heating technology that gets the air to temperature faster – which saves you times every day. It uses less fuel, which saves on your operating costs.

3. It uses bolt-together construction that makes for a more solid, more stable device. Our walls are built panels filled with 100mm mineral wool insulation, which helps keep the heat in the powder coating oven and out of your work area.

4. The entire design is built to create optimal airflow throughout the powder coating oven enclosure, preventing hot spots and providing an even, constant cure for your parts.

More detail about LUX & BRILLIANCE TECHNOLOGIES SDN. BHD.