When maximum flexibility and perfect coating quality are required, robots are the initial choice COLO developed multi-axis robots specially for the coating industry equipped with modern powder application technology. Once programmed, the coating robots efficiently coat parts to the highest quality with magic.

1. Achieve uniform and reproducible coating results,

2. Get more profits through increased efficiency,

3. Optimize the labor cost and material cost.

4. Get easy adjustment and storage of various programs and parameters

5. Improve working conditions

Automatic Powder Spray Gun for Robot Coating

Automatic Powder Spray Gun for Robot Coating Automatic Liquid Paint Gun for Robot Coating

Automatic Liquid Paint Gun for Robot Coating

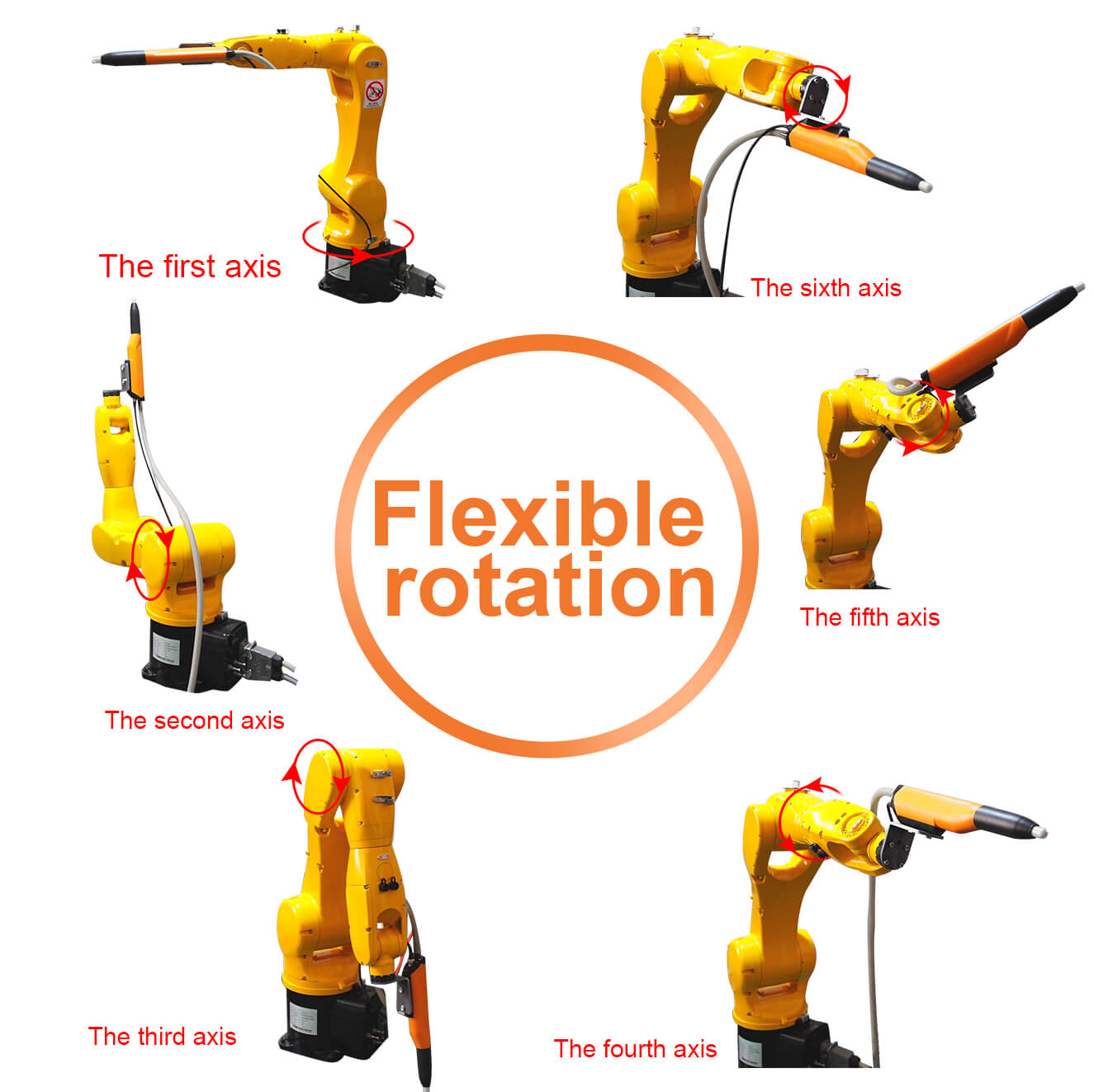

COLO coating robot is a six-axis joint structure, with six servo motors driving the rotation of the six joint axises through the reducers and synchronous pulleys. It has six degrees of freedom, namely rotation (X), lower arm (Y), upper arm (Z), wrist rotation (U), wrist swing (V) and wrist rotation (W).

1. Robot joints are made of high-intensity aluminum, ensuring the precision and reliability in high-strength and high-speed working.

2. Constructed by servo motor and harmonic reducer, features small dimension, wide working range, high speed and accurate.

3. It can be integrated with auxiliary equipment such as turntable and sliding conveyor system.

4. Designed fully sealed that is dustproof, waterproof and explosion-proof, with an IP grade of 67.

5. Palm-type conversational operation control system easy to learn, very suitable for production use.

6. Highly flexibille robot can realize spraying on the outer surface and inner surface that saves painting materials.

7. Robot body is internal wiring that is safe and environmental-friendly.

| Item | Content | Data |

| Specifications | Max. Running Radius | 1500mm |

| Max. Loading | 10kgs | |

| Repeated Posisioning Accuracy | ±0.08mm | |

| Protection Grade | IP67 | |

| Total Weight | 140kgs | |

| Range of Motion | J1 | -180° ~ +180° |

| J2 | -90° ~ +90° | |

| J3 | -75° ~ +255° | |

| J4 | -180° ~ +180° | |

| J5 | -120° ~ +120° | |

| J6 | -360° ~ +360° | |

| Max. Speed | J1 | 150°/s |

| J2 | 150°/s | |

| J3 | 250°/s | |

| J4 | 450°/s | |

| J5 | 650°/s | |

| J6 | 450°/s |

1. Guns are suitable for plastic and metallic powders based on the latest spraying technology.

2. Robust spraying guns with a large selection of nozzles and are an important key to mastering complex coating requirements.

3. The high transfer efficiency significantly increases the productivity of the system and the low weight is also suitable for

coating robots with a low payload.

4. The internal installation of hose, pneumatic and power lines means that they are guided centrally within the robot arm that gives the robot complete mobility.

5. In over long periods coating time, COLO pump technology always achieves constant and reproducible quality. Long hose lengths and bends in the robot arm have no impact on powder output.

6. An interface between the robot control and gun control is necessary to synchronize movement and spraying As the robot movements are performed by a robot control. The coating technology with all its parameters and programs is controlled by a separate gun control unit.

7. Provides various programming methods based on workpiece shape, series size and quality requirements,

More detail about LUX & BRILLIANCE TECHNOLOGIES SDN. BHD.