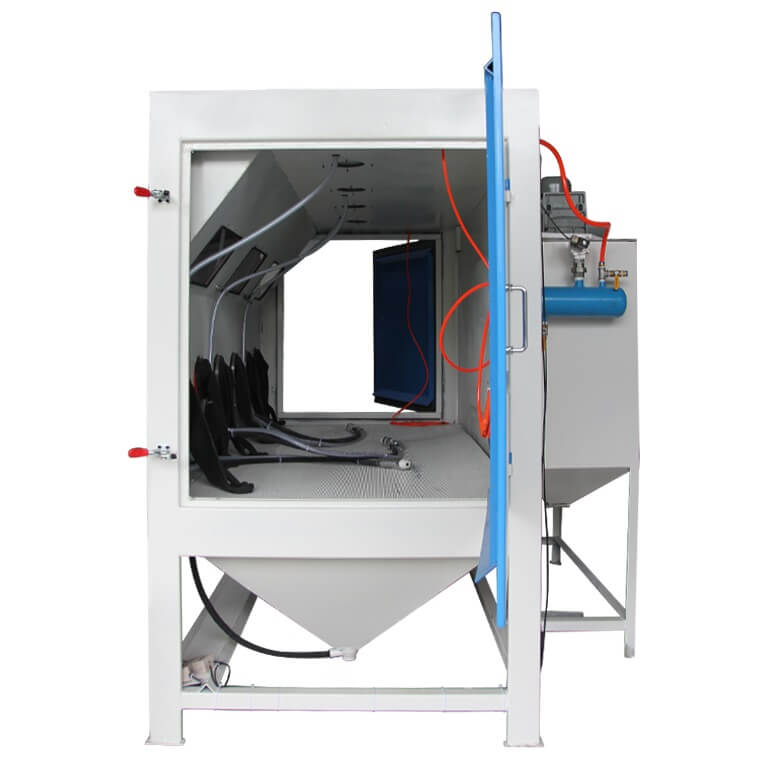

The large sand blasting cabinet is specially designed with multi stations that supports surface treatment of oversized workparts. We can design blast cabinet with 2, or 3 or more working stations to meet your demands.

Sand blasting cabinet works through compressed air to deliver the abrasive to surfaces of substrates, causing grinding or stripping actions. It is an ideal choice for various applications, such as removing impurities, oxide layer, old coatings to obtain a smooth and clean surface, as well as matte finishing or carving for decoration purposes.

1. Standard configuration is a filter cartridge dust collector with fan that effectively removes dust keeping clear working chamber. Could be optionally designed with cyclone separator for special application, such as using ultra fine abrasives.

2. A bottom funnel contains blasting abrasives that can be recycled for many times, a great saving of production expense.

3. Our sandblaster cabinet is welded from 2mm durable steel plate, whose surface is powder coated, sturdy and wear-resistance.

4. Assembled shipment, only requires simple electric and pneumatic connection when you receive the blaster before use.

5. Sizes and special types can be custom-designed as we have experienced technical and manufacture teams.

Working Chamber: enclosed type blaster is environmental to workshop

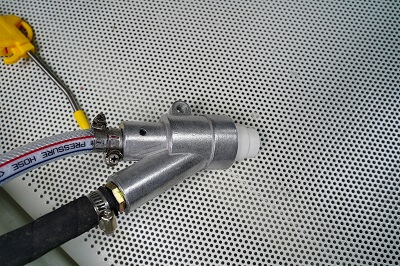

Working Chamber: enclosed type blaster is environmental to workshop Aluminum Alloy Blasting Gun with Boron Carbide Nozzle

Aluminum Alloy Blasting Gun with Boron Carbide Nozzle Foot pedal switch ensure safety and reduce fatigue.

Foot pedal switch ensure safety and reduce fatigue.

| Model | COLO-2810-3 |

| Working Chamber Size | Length2095 x Wdith995 x Height1800 (mm) |

| Overall Size | Length2100 x Wdith1000 x Height800 (mm) |

| Dust Collector Fan Motor | 1.1kw |

| Voltage | 110V/220V (custom as local) |

| Frequency | 50-60HZ |

| Lighting | 18w fluorescent |

| Blasting Gun | 3 piece, with boron carbide nozzle |

| Compressed Air Pressure | 5-8 bar(kg/cm2) |

| Air Flow | 0.6-1m3/min(1 cubic) |

Other sizes can be made as required, pls feel freely to contact with us!

More detail about LUX & BRILLIANCE TECHNOLOGIES SDN. BHD.