PLA polylactic acid fully degradable foamed sheet production line adopts double-machine tandem high-fire gun sheet production technology and environmentally friendly CO2 as foaming agent. It is independently researched and manufactured by our company and has many invention patents and utility model patents.

Tongjia Machinery has formed a series of models for the production of PLA fully degradable foam sheet production equipment, TJ65/90, TJ90/120, TJ120/150 three special mechanical products, production capacity of 100kg ~ 300kg per hour, production of products The width of 600 ~ 1200mm, product thickness of 0.5 ~ 8mm, expansion ratio of 20 ~ 30 times, can fully meet the current stage of PLA full degradation foam sheet production and processing.

Equipment components:

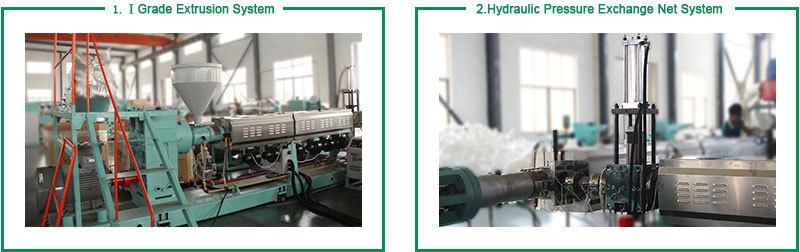

1. Primary extrusion system 2. Hydraulic screen change system 3. Secondary extrusion system 4. Foaming agent injection system

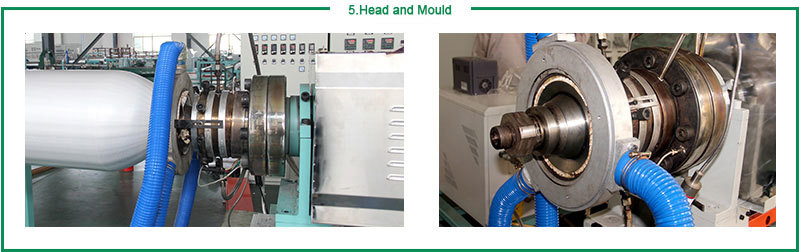

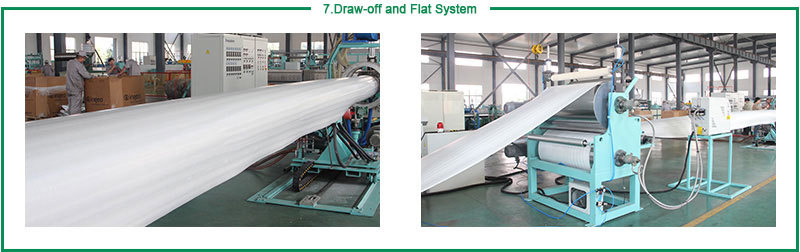

5. Head mould 6. Sizing system 7. Traction flattening system 8. Coiling system

|

Model |

|

JG-PLA65/90 |

JG-PLA100/120 |

JG-PLA135/150 |

|

Extruder |

|

Φ65/Φ90 |

Φ100/Φ120 |

Φ135/Φ150 |

|

Foam rate |

times |

8-18 |

8-18 |

8-18 |

|

Width of product |

mm |

300-640 |

640-1200 |

640-1200 |

|

Cutting method |

|

Double cutter |

||

|

Thickness of product |

mm |

1.0-2 |

1.0-3.5 |

2.0-5.0 |

|

Cooling method |

|

Cooled by wind and water |

||

|

Output (approx) |

kg/h |

60-80 |

150-200 |

180-300 |

|

Installed capacity (approx) |

KW |

100 |

180 |

260 |

|

Dimensions (L×W×H)(approx) |

m |

20x8x2.8 |

23x9x3 |

25x10x3.2 |

|

Total weigh(approx) |

T |

10 |

15 |

18 |

The PLA sheet products produced by this production line are mainly used in the field of food packaging, namely fast food boxes (pallets).

It is used to replace polystyrene foamed sheets and eliminate white pollution. It has a good application prospect and greatly solves environmental problems such as white pollution and oil consumption.

Malaysia

Malaysia