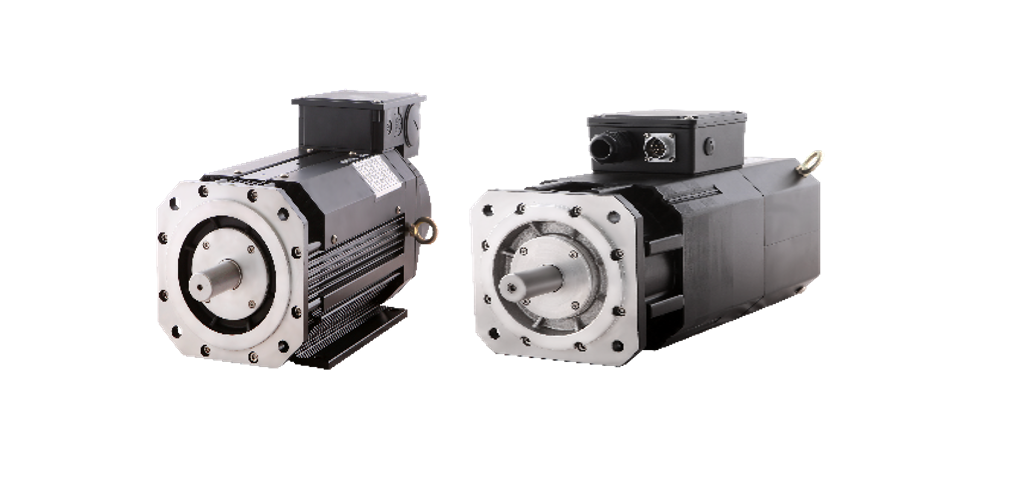

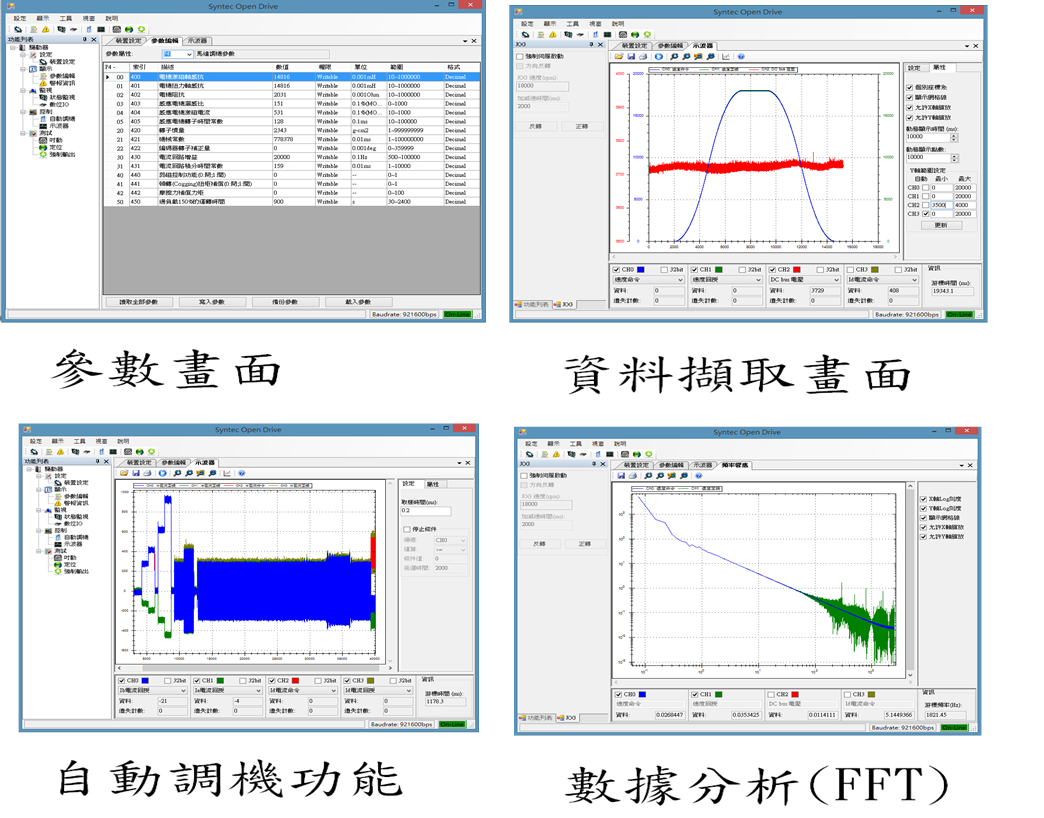

- Mechatrolink III as connection Interface -Multiple servo drive specifications choices for diverse applications - Various spindle servo motor specifications - Integrated high-speed serial communication interface - Support multiple servo motor drive functions - New servo tuning tool Syntec Analytics - Multiple application control functions and simple operation interface

The transmission interface is upgraded to Mechatrolink III

-The transmission rate is increased to 100Mbps, and control information (such as motor position, speed, etc.) is transmitted and received at a higher speed -A maximum transmission distance of 100 meters between stations can be achieved without a repeater

Malaysia

Malaysia