Improve Battery Quality with Waveform Analysis. Boost the Inspection Performance of Safety Testing

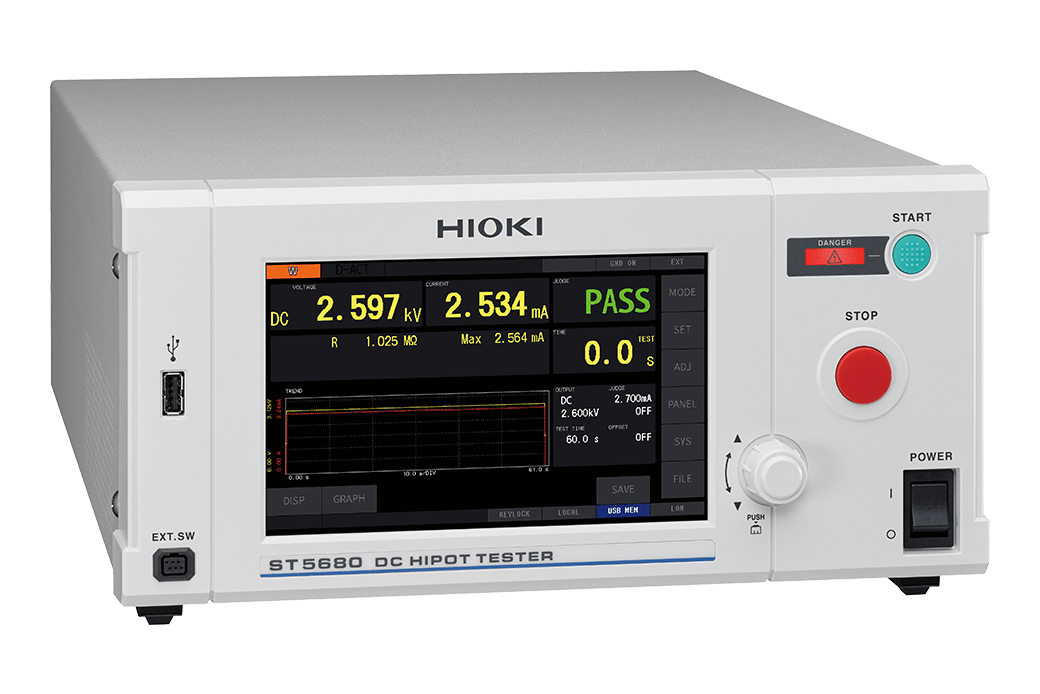

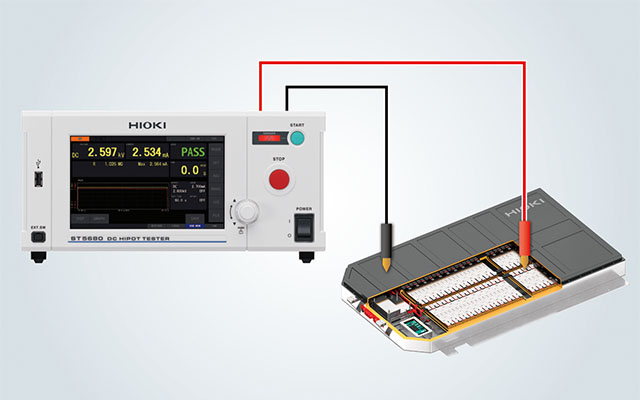

The DC Hipot Tester ST5680 tests for reliable insulation with a waveform by applying a high voltage to the object under test. The instrument applies a DC voltage between test locations and measures leakage current to determine insulation performance.

- Verify battery safety and insulation performance using the waveform.

- High-spec model specifically designed for DC withstand voltage testing. With support for an array of delivery inspections.

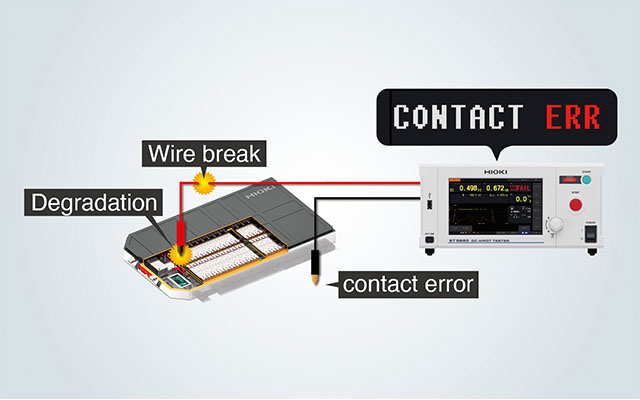

- Features arc detection and contact check functions to prevent shipment of defective batteries.

The ST5680 is a DC Hipot tester that can perform DC withstand voltage testing and insulation resistance testing in compliance with a variety of safety standards. In addition to generating PASS/FAIL judgments, the instrument can display and record applied voltage waveforms and leakage current waveforms acquired during testing. Its ability to visualize and analyze testing is useful from a test traceability standpoint.

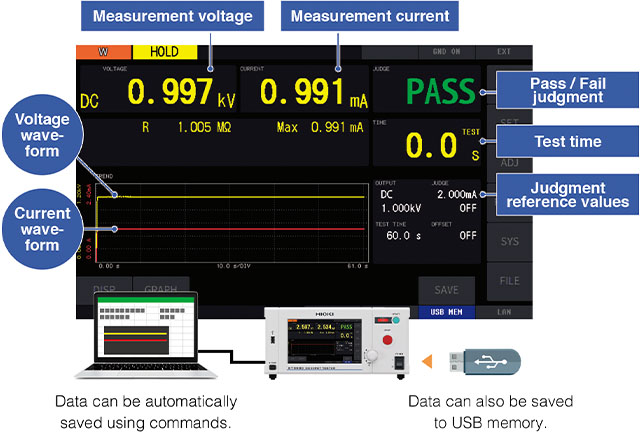

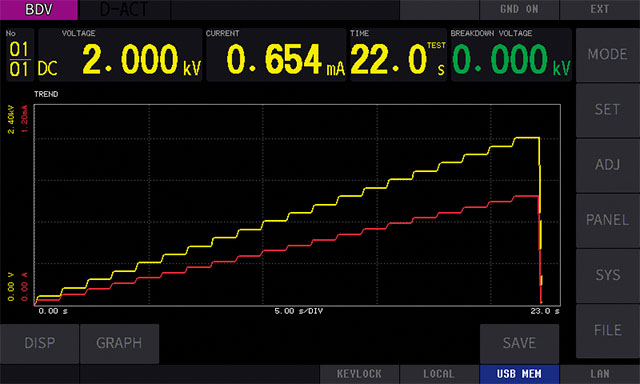

Waveform display of applied voltage and measured current

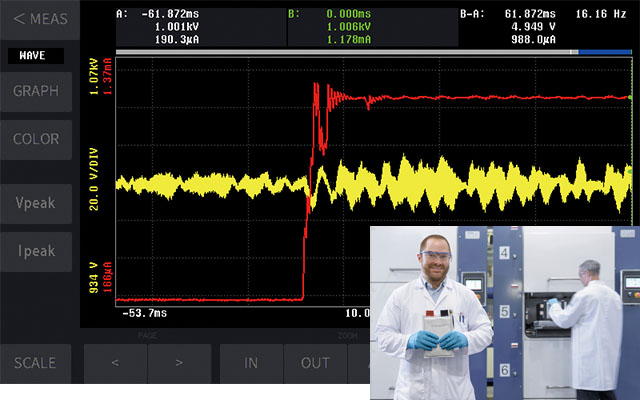

The behavior of the applied voltage and measured current can be checked by monitoring the waveforms. In addition, the instrument can display voltage, current, and resistance measured values as a time series so that behavior can be reviewed. It can also display an enlarged view of just the waveforms for more detailed review. In this way, the ST5680 lets you analyze results immediately in the field, without using a computer.

Improving production processes

By analyzing waveforms during testing, you can infer the causes of defects in production processes. And by identifying those causes and improving the processes, you can improve production efficiency.

Analyzing defective parts returned from the market

You can also look back at results, at the waveform level, from shipping inspections of products that were later returned due to defects. By improving the standards based on which PASS judgments are made, you can boost production quality.

Promoting inspection quality

The ability to record and manage waveforms is useful from an inspection traceability standpoint. By developing higher-quality testing structures, you can increase the trust of customers.

The ST5680 can detect arc discharges, which are caused by residual materials like burrs and cuttings. By correctly identifying parts with minuscule insulation defects as defective, the instrument helps prevent the risk of hazards such as fires and accidents caused by heating after shipment.

The instrument can determine whether it has made proper contact with the test target by measuring the capacitance between the measurement terminals (stray capacitance and the capacitance of the test target).

The ST5680 tests insulation performance by applying a high voltage to the test target. It’s capable of performing safety testing for a broad assortment of targets, including electronic devices, electronic components, and materials, in settings ranging from R&D labs to production lines. For batteries, it’s used to perform withstand voltage testing between the enclosures and electrodes of modules, packs, and cells.

The ST5680 provides two modes: DC withstand voltage test mode, which evaluates insulation by measuring the leakage current in the test target, and insulation resistance test mode, which evaluates insulation by measuring resistance.

In DC withstand voltage testing, it can output up to 8 kV, one of the highest values for any instrument of its kind. Test cycle times can be reduced since it can charge test targets quickly with high-capacity, 100 mA output, even if the target includes a capacitance component.

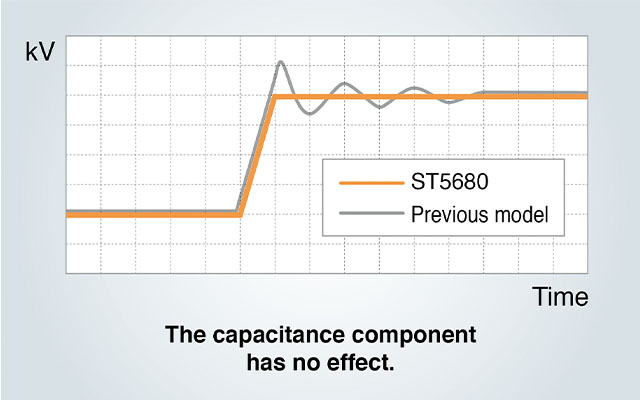

Even if your test target includes a capacitance component, an overshoot-resistant design ensures the ST5680 won’t exceed the set voltage when applying voltage to the target, allowing you to perform tests with peace of mind.

In addition, you can set a delay time so that no judgments are made while the charging current continues to flow, helping prevent erroneous judgments.

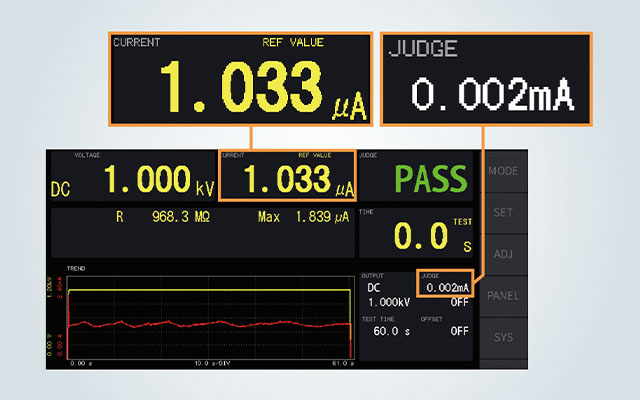

As the insulation performance of batteries and motors improves, there’s growing demand for the ability to use ever more minuscule current values to generate PASS/FAIL judgments in withstand voltage testing. If you use a withstand voltage tester with low resolution, you won’t be able to accurately measure leakage current. Since the ST5680 realizes high-precision performance with a maximum resolution of 0.001 μA, it can accurately measure minuscule leakage currents and use them to generate PASS/FAIL judgments.

The ST5680’s BDV function can check the insulation breakdown voltage of the test target. It can increase the applied voltage at a set speed and check the voltage that leads to insulation breakdown. Test methods are defined by standards, including continuous voltage rise testing and stepped voltage rise testing. The ST5680 can perform both tests. The instrument can be used to evaluate insulation performance (dielectric strength) in R&D work.

| Main functions | DC Hipot test, Insulation resistance test, Breakdown voltage test, Waveform display functionality, Arc discharge detection, Contact check function See "Various Tests and Functionality" table for details |

|---|---|

| List of other features | Interlock, GFI, Auto discharge, Offset cancellation, Set voltage modification during testing, Momentary out, Command monitor, I/O handler test, Key lock, Self-check, Calibration deadline check, EXT SW (Remote control) |

| Operating temperature and humidity range | 0°C to 40°C (32°F to 104°F), 80% RH or less (non-condensing) |

| Standards | Safety: IEC 61010 EMC: IEC 61326 Class A |

| Power supply | 100 to 240 V AC |

| Power consumption | Approx. 180 VA Power supply conditions are 220 V power supply voltage, 50 Hz/60 Hz power supply frequency, DC withstand voltage test mode, 2.5 kV test voltage, and 5 mA load current (500 kΩ load resistance). |

| Maximum rated power | 800 VA |

| Interface | Communications: USB, LAN, EXT I/O Options: RS-232C (Z3001), GP-IB (Z3000) Memory: USB drive |

| Dimensions and mass | Approx. 305 mm (12.01 in) W × 142 mm (5.59 in) H × 430 mm (16.93 in) D (excluding protruding parts), Approx. 10 kg (352.7 oz) |

| Included accessories | Power cord ×1, CD ×1 (PDF: Instruction Manual, Communication Instruction Manual), EXT I/O male connector ×1, EXT I/O connector cover ×1, Custom-made interlock-canceling connector for the EXT I/O ×1, Startup Guide ×1 |

| DC Hipot test | Output voltage: DC 0.010 kV to 8.000 kV (1 V resolution) Load regulation: ±1% or less Output setting accuracy: ± (1.2% of setting + 20 V) Output current/cutoff current: Max. 100 mA Current accuracy: > 3.00 mA: ±(1.5% rdg. + 2 μA) ≤ 3.00 mA: ±1.5% rdg. Maximum resolution: 0.001 μA Test time: 0.1 s to 999 s, continuous (timer off) Voltage ramp up / ramp down time: 0.1 s to 300 s / 0.1 s to 300 s, off Short-circuit current: 200 mA or less Test modes: W to IR, IR to W, program test |

|---|---|

| Insulation resistance test | Output voltage: 10 V DC to 2000 V (1 V resolution) Output setting accuracy: ± (1.2% of setting + 2 V) Resistance value display range: 10.00 kΩ to 200.0 GΩ (0.01 kΩ resolution) Accuracy guarantee range: 10.00 kΩ to 99.99 GΩ Resistance accuracy: ±(1.5% rdg. + 3 dgt.) See "Insulation resistance measurement accuracy" table for details Test time: 0.1 s to 999 s, continuous (timer off) Voltage rise/fall time: 0.1 s to 300 s / 0.1 s to 300 s, off |

| Breakdown voltage test | Test method: Continuous voltage rise test, stepped voltage rise test Measurement: Insulation breakdown voltage (kV), insulation breakdown strength (kV/mm) Settings: Start voltage, end voltage, rise speed, arc detection, electrode distance, upper limit current |

| Waveform display functionality | Waveform display: Voltage, current, insulation resistance Sampling rate: 500 kS/s Resolution: 256 K words |

| Arc discharge detection | Detection method: Monitoring of fluctuations in the test voltage Settings: Test voltage variability 1% to 50% |

| Contact check functionality | Detection method: Capacitance measurement method Settings: Threshold (capacitance) setting 1.0 nF to 100.0 nF |

| Memory functionality | - Saving of waveforms/graphs: Save to USB memory Save formats: BMP, PNG, CSV - Panel memory function: Saves test condition settings internally in the instrument DC withstand voltage testing/insulation resistance testing: Up to 64 sets of settings each Program testing: Up to 30 programs (max. 50 steps) Insulation breakdown voltage testing: Up to 10 sets of settings - Data memory function Saves measured values in the instrument’s internal memory (up to 32,000 values) |

| Judgment functionality (Judgment output) | PASS judgment, FAIL judgment (UPPER FAIL, LOWER FAIL) UPPER_FAIL : Measured value > upper limit value PASS : Upper limit value ≥ measured value ≥ lower limit value LOWER_FAIL : Measured value < lower limit value |

| Measurement range | 10 kΩ to 99.99 GΩ (*1) | |

|---|---|---|

| 10 nA ≤ I ≤ 3 μA | 100 MΩ ~ 999.9 MΩ 1.00 GΩ ~ 99.99 GΩ |

± (20% rdg.) *2, *3, *4 |

| 100 nA ≤ I ≤ 30 μA | 10.00 MΩ ~ 99.99 MΩ 100.0 MΩ ~ 999.9 MΩ |

± (5% rdg.) *2, *3, *4 |

| 1 μA ≤ I ≤ 300 μA | 1.000 MΩ ~ 9.999 MΩ 10.00 MΩ ~ 99.99 MΩ |

± (2% rdg. + 5 dgt.) *2, *3, *4 |

| 10 μA ≤ I ≤ 3 mA | 100.0 kΩ ~ 999.9 kΩ 1.000 MΩ ~ 9.999 MΩ |

± (1.5% rdg. +3 dgt.) *2, *3, *4 |

| 100 μA ≤ I ≤ 30 mA | 10.00 kΩ ~ 99.99 kΩ 100.0 kΩ ~ 999.9 kΩ |

± (1.5% rdg. +3 dgt.) *2, *3, *4 |

| 1 mA ≤ I ≤ 100 mA | 10.00 kΩ ~ 99.99 kΩ | ± (1.5% rdg. +3 dgt.) *2, *3, *4 |

Malaysia

Malaysia