X5600 industrial X-ray inspection machine can quickly select and mark a single solder ball, or select the solder balls to be inspected by matrix box; it can manually or automatically identify BGA solder balls and complete the inspection. Follow the system guidelines to easily complete the inspection process and ensure accurate and reliable inspection results.

Measuring tools

Distance, distance ratio, lines distance, angle, arrow mark, circle radius, point distance, circle centres distance, circumference, hand-drawn polygon, hand-drawn freeform, etc. can add a text description.

X5600 can automatically detect the size, area, broken wire, bridging, etc.

Customerized software algorithms based on product features and request to achieve fully automatic defect inspection algorithms, including Y/N, crack, broken wire, offset size, and quantity, etc.

X5600 supports CNC multi-point automatic inspection mode, based on product feature set multi-point coordinates for automatic inspection.

Automatically save images, generate reports, also support batch inspection.

The X5600 detector produced by Zhuomao supports a tilt angle of ±30°. For cases where the photo taken on the front of a special device cannot identify the defect feature, the tilt function can be used to observe the device features at multiple angles, making it easier to analyze and identify the defect.

Equipped with a rotating manipulator that can rotate 360 degrees to take images, no dead angle for defects observation.

| X-Ray Tube Source Specification | |

| Type | Sealed Micro-Focus X-Ray Tube |

| voltage Range | 40-90KV |

| current Range | 10-200 μA |

| Max Output Power | 8 W |

| Micro Focus Spot Size | 15μm |

| Flat Panel Detector Specification | |

| Type | TFT Industrial Dynamic FPD |

| Pixel Matrix | 768×768 |

| Field of View | 65mm×65mm |

| Resolution | 5.8Lp/mm |

| Frame(1×1) | 40fps |

| A/D Conversion Bit | 16bits |

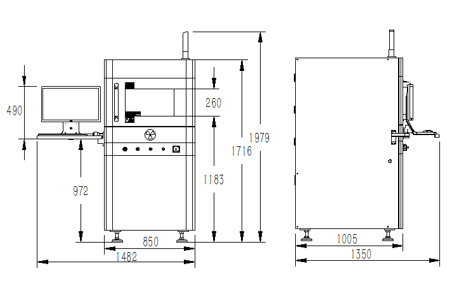

| Dimensions | L850mm×W1000mm×H1700mm |

| Input Power | 220V 10A/110V 15A 50-60HZ |

| Max Sample Size | 280mm×320mm |

| Control System | Industrial PC WIN7/ WIN10 64bits |

| Net Weight | About 750KG |

Malaysia

Malaysia