Many pickling processes for stainless steel produce hazardous nitric fumes. To address this issue, we’ve introduced ONE Technology, which offers a unique, low-fuming pickling spray, reducing toxic nitric fumes by 60%.

Our pickling spray restores stainless steel surfaces that undergo damage during fabrication operations like welding, forming, cutting, and blasting. It effectively eliminates weld oxides, the underlying chromium-depleted layer, and other defects that can lead to local corrosion. Avesta RedOne™ Pickling Spray 240 is versatile and ideal for spray pickling larger surfaces of all stainless steel grades. High-alloyed steels and duplex steels may require multiple treatments. As a stronger alternative for duplex steels, we recommend the Avesta Duplex Spray 250.

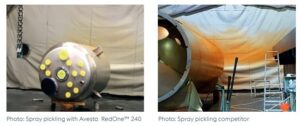

Our ONE Technology brings about a 60% reduction in NOx emissions, ensuring workers are safe from hazardous acid fumes. Please refer to the enclosed photos showing yellow NOx fumes during pickling staining caused by various factors like sea water, “tea-staining,” rainwater, “water scale,” and road salt. In cases of more severe surface rust, additional pickling may be necessary. The spray offers perfect adhesion and high efficiency, thanks to its thixotropic properties. After shaking, it becomes very fluid and easy to spray. Once applied to the surface, it regains excellent adhesion.

Avesta RedOne™ Pickling Spray 240 is available in 20kg, 30kg, and 220kg polyethylene containers, or 1200kg IBC polyethylene containers. Package sizes may vary by market, and all packaging materials comply with UN regulations for hazardous goods.

Properly store Avesta RedOne™ Pickling Spray 240 indoors at room temperature. Ensure that containers remain securely closed, in an upright position, and out of reach of unauthorized individuals. The product is perishable and should not be stored longer than necessary. If the spray decomposes during storage, please stir it before usage. It has a maximum shelf life of two years when stored at room temperature. Avoid exposure to higher temperatures (>35°C) to prevent damage and a reduction in shelf life.

To further enhance results, we recommend a passivation step after pickling using Avesta FinishOne Passivator 630, a safer-to-use acid-free passivation method.

The wastewater produced during pickling contains acids and should be treated with Avesta Neutraliser 502 or slaked lime to achieve a pH value of 7 – 10 before discharge. Heavy metals from stainless steel precipitate as a sludge and should be disposed of in accordance with local regulations. Empty containers (HDPE) must be cleaned and can then be recycled as per local regulations.

Malaysia

Malaysia