Dairy production is one of the rapidly growing industries with major water consumption. Increased in the demand for dairy products, increased the water consumption hence the wastewater production increases. Wastewater as a byproduct generated during processing of milk and other dairy products.

The process water requires to be used in milk processing where milk is transformed into cheese, yogurt, or butter, for the purpose of cooling, cleaning etc. In cheese, yogurt and butter production, wastewater is being generated from equipment cleaning, cooling the curds and from the whey separation during cheese making process. Apart from the production waste, services as cleaning and sanitation for dairy facilities which requires extensive amount of water contributes to dairy wastewater.

Dairy wastewater contains high concentrations of organic and inorganic substances that cause eutrophication in water bodies. Significant contaminants in dairy wastewater are Chemical Oxygen Demand (COD), Biological Oxygen Demand (BOD), Total Suspended Solids (TSS), Fatty acid (FOG), Total Phosphorus (TP), Total Nitrogen (TN) etc. These contaminants are difficult to treat in single step conventional treatment technique.

Combination of physicochemical and biological treatments are required to treat dairy wastewater. A major challenge usually faced by dairy wastewater treatment is removal of emulsified fat, oil, and grease (FOG), Due to its nature as insoluble in water, it floats on water and quickly turns into soap in an alkaline medium. Oleic acid (scientific name of fatty acid) is a hydrophobic and converts into sodium oleate, which is soap. The soap-kind properties reduce the efficiency of biological treatment. Beforehand, fatty acids need to be removed/separated before it passes to chemical/biological treatment.

As a pretreatment, gravity separator is used to remove the emulsified/solid fatty acid from the stream. Gravity will be used as primary force for the separation, as the fatty acids are less dense than water, it will float on the surface. A skimming mechanism is used to skim the floating FOG and dispose of it separately. Apart from gravity separator, Dissolved Air Floatation (DAF) also can be used as physical-chemical treatment for the removal of FOG, Total Suspended Solids (TSS) and colloids. With proper chemical adjustment, the DAF with good white-water formation could be able to remove 70~80% of FOG and 90% of TSS.

.png)

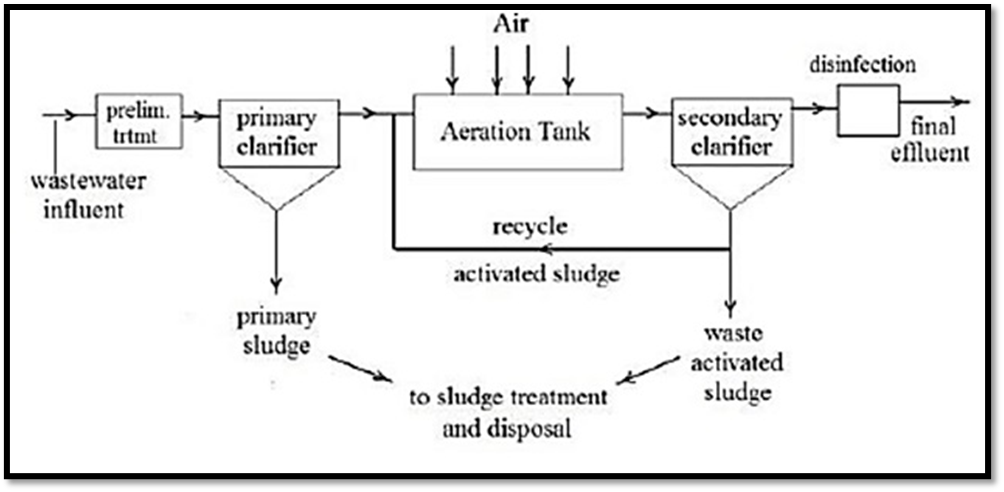

Based on COD/BOD ratio, the type of wastewater treatment will be determined for better treated water quality for dairy industries. Commonly, dairy wastewater is high loading in organic impurities such as Biological Oxygen Demand (BOD), nutrients, where preferred treatment method is biological process.

Type of Biological Treatments in dairy wastewater system:

Malaysia

Malaysia