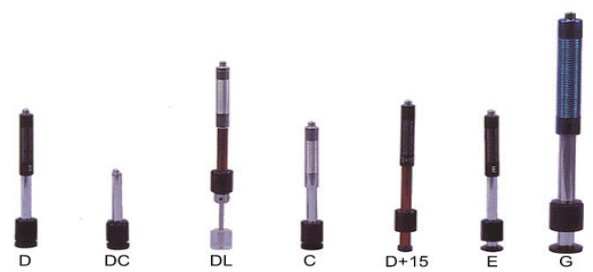

ACCESSORIES FOR PORTABLE LEEB HARDNESS TESTER

IMPACT DEVICES FOR HARDNESS TESTER

Impact device D: Universal device for most hardness requirements

Impact device DC: Ultra-short version; manually loaded on the front; same characteristics as type D;

for testing in boreholes,built-in parts, hollow cylindrical parts, etc.; max. 940 HV

Impact device DL: With extremely long and fine front piece only for steel and cast steel; for testing in

narrow or hard to reach areas; max. 950 HV

Impact device D+15: The front part is narrow and the coil is located behind it; same characteristics as

type D; only for steel;for hardness testing in slots, grooves, recessed areas, gear flanks,grooves, cavities,

tooth flanks, etc.; max. 940 HV

Impact device C: Reduced impact energy of about 1/4 of type D; for tempered or surface treated steel,

small or sensitive-to-shock parts (minimal imprint is left); max. 1000 HV

Impact device G: With large test-tip diameter; impact energy 9 times larger than type D; on steel, gray

or nodular cast iron; for large cast parts and forgings or parts with high surface roughness;max. 650 HB

(only in Brinell)

Impact device E: With a synthetic diamond test tip of approx.5000 HV; for very hard materials (above 50

HRC / 650 HV) such as carbide, barrels, etc.; max. 1200 HV

|

Material |

Method |

Impact device |

|||||

|

D/DC |

D+15 |

C |

G |

E |

DL |

||

|

Steel and cast steel

|

HRC |

20~68.5 |

19.3~67.9 |

20.0~69.5 |

|

22.4~70.7 |

20.6~68.2 |

|

HRB |

38.4~99.6 |

|

|

47.7~99.9 |

|

37.0~99.9 |

|

|

HRA |

59.1~85.8 |

|

|

|

61.7~88.0 |

|

|

|

HB |

127~651 |

80~638 |

80~683 |

90~646 |

83~663 |

81~646 |

|

|

HV |

83~976 |

80~937 |

80~996 |

|

84~1042 |

80~950 |

|

|

HS |

32.2~99.5 |

33.3~99.3 |

31.8~102.1 |

|

35.8~102.6 |

30.6~96.8 |

|

|

Cold work tool steel |

HRC |

20.4~67.1 |

19.8~68.2 |

20.7~68.2 |

|

22.6~70.2 |

|

|

HV |

80~898 |

80~935 |

100~941 |

|

82~1009 |

|

|

|

Stainless steel

|

HRB |

46.5~101.7 |

|

|

|

|

|

|

HB |

85~655 |

|

|

|

|

|

|

|

HV |

85~802 |

|

|

|

|

|

|

|

Grey cast iron

|

HRC |

|

|

|

|

|

|

|

HB |

93~334 |

|

|

92~326 |

|

|

|

|

HV |

|

|

|

|

|

|

|

|

Nodular cast iron |

HRC |

|

|

|

|

|

|

|

HB |

131~387 |

|

|

127~364 |

|

|

|

|

HV |

|

|

|

|

|

|

|

|

Cast aluminium alloys |

HB |

19~164 |

|

23~210 |

32~168 |

|

|

|

HRB |

23.8~84.6 |

|

22.7~85.0 |

23.8~85.5 |

|

|

|

|

BRASS(copper- zinc alloys) |

HB |

40~173 |

|

|

|

|

|

|

HRB |

13.5~95.3 |

|

|

|

|

|

|

|

BRONZE(copper- aluminium/tin alloys) |

HB |

60~290 |

|

|

|

|

|

|

Wrought copper alloys |

HB |

45~315 |

|

|

|

|

|

|

Available type of impact device |

|

DC: Test hole or hollow cylindrical |

D+15: Test groove or reentrant surface |

C: Test small, light, thin parts and surface of hardened layer |

G: Test large, thick, heavy and rough surface steel |

E: Test super high hardness material |

DL: Test slender narrow groove or hole |

|

Type of impact device |

DC(D)/DL |

D+15 |

C |

G |

E |

|

Impacting energy Mass of impact body |

11mJ 5.5g/7.2g |

11mJ 7.8g |

2.7mJ 3.0g |

90mJ 20.0g |

11mJ 5.5g |

|

Test tip hardness: Dia. Test tip: Material of test tip: |

1600HV 3mm Tungsten carbide |

1600HV 3mm Tungsten carbide |

1600HV 3mm Tungsten carbide |

1600HV 5mm Tungsten carbide |

5000HV 3mm synthetic diamond |

|

Impact device diameter: Impact device length: Impact device weight: |

20mm 86(147)/ 75mm 50g |

20mm 162mm 80g |

20mm 141mm 75g |

30mm 254mm 250g |

20mm 155mm 80g |

|

Max. hardness of sample |

940HV |

940HV |

1000HV |

650HB |

1200HV |

|

Mean roughness value of sample surface Ra: |

1.6μm |

1.6μm |

0.4μm |

6.3μm |

1.6μm |

|

Min. weight of sample: Measure directly Need support firmly Need coupling tightly |

>5kg 2~5kg 0.05~2kg |

>5kg 2~5kg 0.05~2kg |

>1.5kg 0.5~1.5kg 0.02~0.5kg |

>15kg 5~15kg 0.5~5kg |

>5kg 2~5kg 0.05~2kg |

|

Min. thickness of sample Coupling tightly Min. layer thickness for surface hardening |

5mm

≥0.8mm |

5mm

≥0.8mm |

1mm

≥0.2mm |

10mm

≥1.2mm |

5mm

≥0.8mm |

|

Size of tip indentation |

||||||

|

Hardness 300HV |

Indentation diameter Depth of indentation |

0.54mm 24μm |

0.54mm 24μm |

0.38mm 12μm |

1.03mm 53μm |

0.54mm 24μm |

|

Hardness 600HV |

Indentation diameter Depth of indentation |

0.54mm 17μm |

0.54mm 17μm |

0.32mm 8μm |

0.90mm 41μm |

0.54mm 17μm |

|

Hardness 800HV |

Indentation diameter Depth of indentation |

0.35mm 10μm |

0.35mm 10μm |

0.35mm 7μm |

-- -- |

0.35mm 10μm |

Support rings for Shaped Materials

|

No. |

Type |

Sketch of non-conventional Supporting ring |

Remarks |

|

1 |

Z10-15 |

|

For testing cylindrical outside surface R10~R15 |

|

2 |

Z14.5-30 |

For testing cylindrical outside surface R14.5~R30 |

|

|

3 |

Z25-50 |

For testing cylindrical outside surface R25~R50 |

|

|

4 |

HZ11-13 |

|

For testing cylindrical inside surface R11~R13 |

|

5 |

HZ12.5-17 |

For testing cylindrical inside surface R12.5~R17 |

|

|

6 |

HZ16.5-30 |

For testing cylindrical inside surface R16.5~R30 |

|

|

7 |

K10-15 |

|

For testing spherical outside surface SR10~SR15 |

|

8 |

K14.5-30 |

For testing spherical outside surface SR14.5~SR30 |

|

|

9 |

HK11-13 |

|

For testing spherical inside surface SR11~SR13 |

|

10 |

HK12.5-17 |

For testing spherical inside surface SR12.5~SR17 |

|

|

11 |

HK16.5-30 |

For testing spherical inside surface SR16.5~SR30 |

|

|

12 |

UN |

|

For testing cylindrical outside surface, radius adjustable R10~∞ |