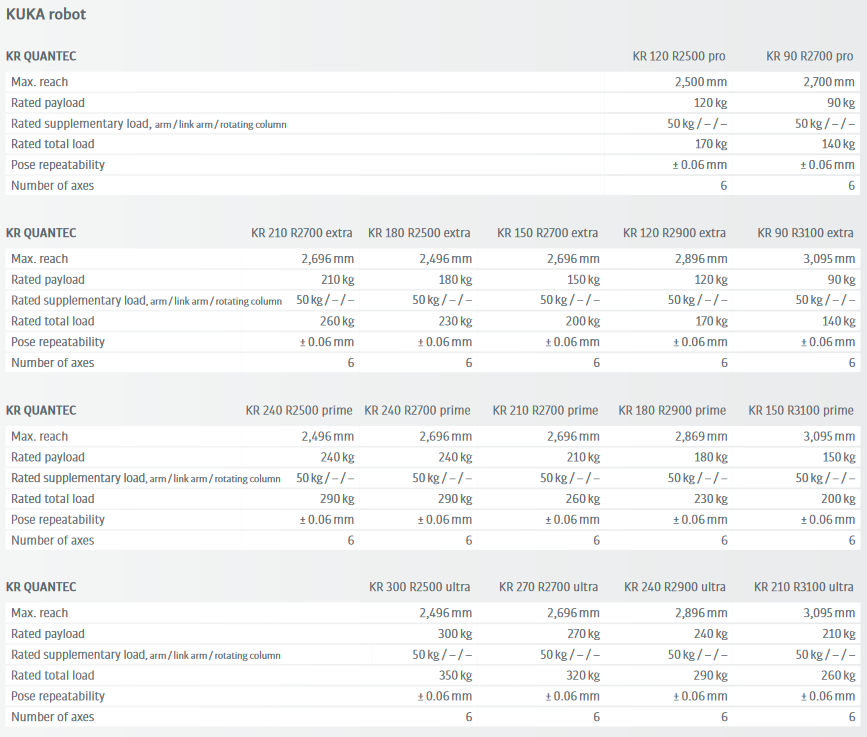

The KR QUANTEC range of heavy-duty robots achieves exceptional performance with top-tier reach and payload capacities within its category. Featuring a versatile design, these robots are engineered to operate across diverse market sectors, including automotive, foundry, medical, and more.

Features :

.png)

| Models |

Total load

|

Maximum reach

|

Version environment

|

|

KR 120 R2700-2

|

120 kg

|

2701 mm

|

Standard

|

|

KR 120 R2700-2 F

|

120 kg

|

2701 mm

|

Foundry

|

|

KR 120 R2700-2 HO

|

120 kg

|

2701 mm

|

Food

|

|

KR 120 R3100-2

|

120 kg

|

3100 mm

|

Standard

|

|

KR 120 R3100-2 F

|

120 kg

|

3100 mm

|

Foundry

|

|

KR 120 R3500-2 P

|

120 kg

|

3505 mm

|

Standard

|

|

KR 120 R3500-2 P-C

|

120 kg

|

3505 mm

|

Standard

|

|

KR 120 R3900-2 K

|

120 kg

|

3904 mm

|

Standard

|

|

KR 150 R2700-2

|

150 kg

|

2701 mm

|

Standard

|

|

KR 150 R2700-2 F

|

150 kg

|

2701 mm

|

Foundry

|

|

KR 150 R3100-2

|

150 kg

|

3100 mm

|

Standard

|

|

KR 150 R3100-2 F

|

150 kg

|

3100 mm

|

Foundry

|

|

KR 150 R3100-2 HO

|

150 kg

|

3100 mm

|

Food

|

|

KR 180 R2900-2

|

180 kg

|

2900 mm

|

Standard

|

|

KR 180 R2900-2 F

|

180 kg

|

2900 mm

|

Foundry

|

|

KR 180 R3500-2 K

|

180 kg

|

3505 mm

|

Standard

|

|

KR 180 R3500-2 K-F

|

180 kg

|

3505 mm

|

Foundry

|

|

KR 210 R2700-2

|

210 kg

|

2701 mm

|

Standard

|

|

KR 210 R2700-2 F

|

210 kg

|

2701 mm

|

Foundry

|

|

KR 210 R3100-2

|

210 kg

|

3100 mm

|

Standard

|

|

KR 210 R3100-2 C

|

210 kg

|

3065 mm

|

Standard

|

|

KR 210 R3100-2 F

|

210 kg

|

3100 mm

|

Foundry

|

|

KR 210 R3300-2 K

|

210 kg

|

3305 mm

|

Standard

|

|

KR 210 R3300-2 K-F

|

210 kg

|

3305 mm

|

Foundry

|

|

KR 240 R2900-2

|

240 kg

|

2900 mm

|

Standard

|

|

KR 240 R2900-2 C

|

240 kg

|

2865 mm

|

Standard

|

|

KR 240 R2900-2 F

|

240 kg

|

2900 mm

|

Foundry

|

|

KR 240 R2900-2 HO

|

240 kg

|

2900 mm

|

Food

|

|

KR 250 R2700-2

|

250 kg

|

2701 mm

|

Standard

|

|

KR 250 R2700-2 C

|

250 kg

|

2671 mm

|

Standard

|

|

KR 250 R2700-2 F

|

250 kg

|

2701 mm

|

Foundry

|

|

KR 270 R3100-2 K

|

270 kg

|

3105 mm

|

Standard

|

|

KR 270 R3100-2 K-F

|

270 kg

|

3105 mm

|

Foundry

|

|

KR 300 R2700-2

|

300 kg

|

2701 mm

|

Standard

|

|

KR 300 R2700-2 C

|

300 kg

|

2671 mm

|

Standard

|

|

KR 300 R2700-2 C-F

|

300 kg

|

2671 mm

|

Foundry

|

|

KR 300 R2700-2 F

|

300 kg

|

2701 mm

|

Foundry

|

Malaysia

Malaysia