Description

The CRISTAL range is made of furnaces dedicated to vacuum heat treatments at high temperature. The hot zone is insulated with specific metals, with a possible choice of molybdenum or tungsten resistors depending on the desired treatment temperature. It is the perfect tool for clean treatments for medium to large scale production. Its bell design allows for a precise positioning of the load. The patented resistor design ensures exceptional precision while piloting your process.

DIMENSIONS

- CRISTAL 40-40

- CRISTAL 40-60

- Automotive

- Aeronautics

- Medical

- Electronics

- Additive Manufacturing

ADVANTAGES

The CRISTAL range allows to vacuum heat treat parts with a wide range of working temperatures. Indeed, depending on the selected heating elements, working temperatures can reach up to 2300°C. In addition, CRISTAL furnaces are adapted to a large scope of applications and enable clean treatments, at high temperatures. Loading is simplified by an easy access to the hearth, which ensures a precise positioning of parts. The best treating conditions are then gathered.

PROCESSES

- Tempering

- Degassing

- Hyper-Quench Hardening

- Brazing

- Sintering

- Magnetic Annealing

- Glass to Metal Sealing

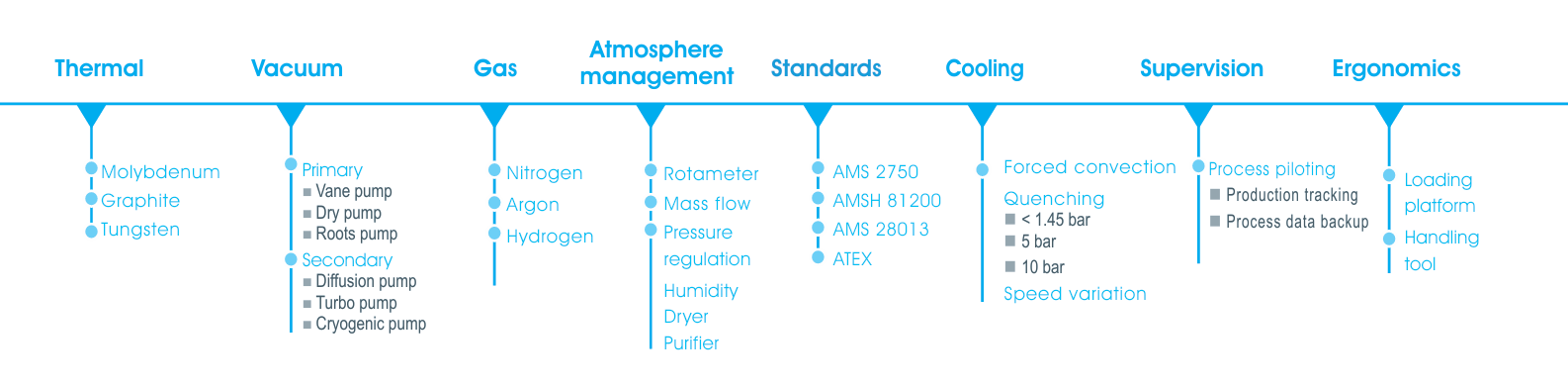

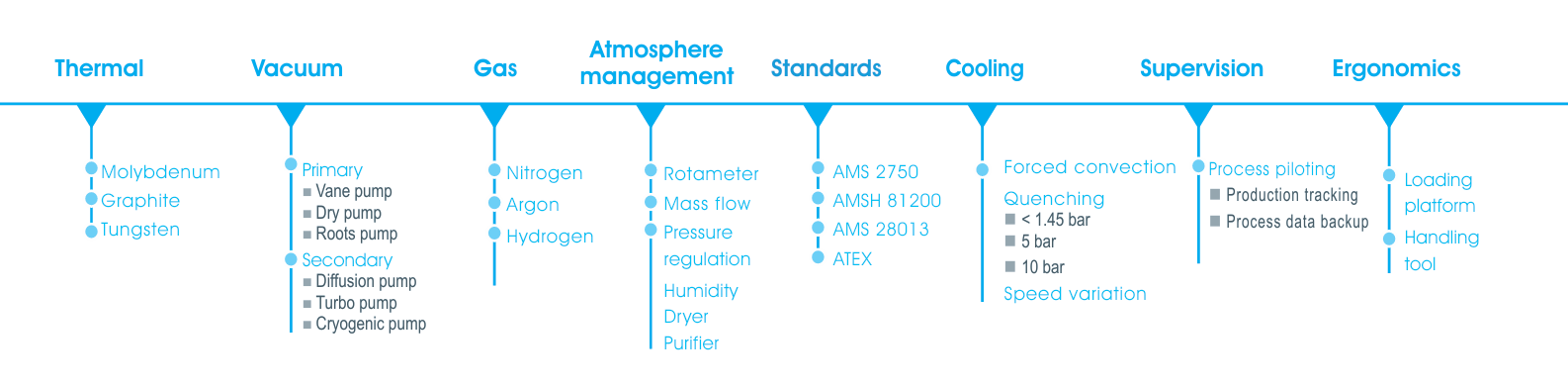

AVAILABLE CONFIGURATIONS

VACUUM FURNACES RANGE

VACUUM FURNACES RANGE

More detail about Obsnap Instruments Sdn. Bhd.

Malaysia

Malaysia