Description

Model : SHO -5331 -1005GJ -QX

Features :

- Intelligent Automatic Rinsing: Multiple automatic cleaning modes to suit various environments.

- Anti-Solidification System: Prevents glue hardening and blockages in pipes and valves during pauses.

- Cleaning Agent Recycling: Enhances cleaning agent efficiency, reducing waste.

- Anti-Solidification Mode: Prevents mixing head solidification due to employee oversight.

- Liquid Level Sensors: Automatic alarm and machine stop when material is insufficient or full.

- Glue Stirring and Heating: Optional heating and vacuum degassing functions for various glue types.

- Production Monitoring: Includes production counting, timing, and operational alarms.

- AB Pump Setting Wizard: Adapts to different glue types with pulse coefficient settings.

- Flow Monitoring: Ensures accuracy in high glue ratios with small error margins.

- Stable Glue Output: Not affected by air pressure, preventing uneven discharge and leaks.

- Fully Automatic Operation: Integrates glue preparation, filling, and track filling.

- Efficient Glue Mixing: Adjustable mixing ratio from 1:1 to 10:1 with uniform static or dynamic mixing.

- Large Storage Capacity: Stores unlimited programs without the need for reprogramming.

- Comprehensive Software: Includes array, translation, and rotation calculations for precision.

- Adjustable Parameters: Glue volume, speed, dispensing time, and stop time can all be set.

- Advanced Gluing Functions: Handles points, lines, surfaces, arcs, circles, and irregular curves with three-axis linkage.

- Multiple Dispensing Modes: Can dispense A glue, B glue, or AB glue in various quantitative modes.

- Five-Stage Quantitative Dispensing: Allows for separate settings of glue output and speed at each stage.

- Automatic Feeding and Suction: Improves work efficiency by reducing manual feeding time.

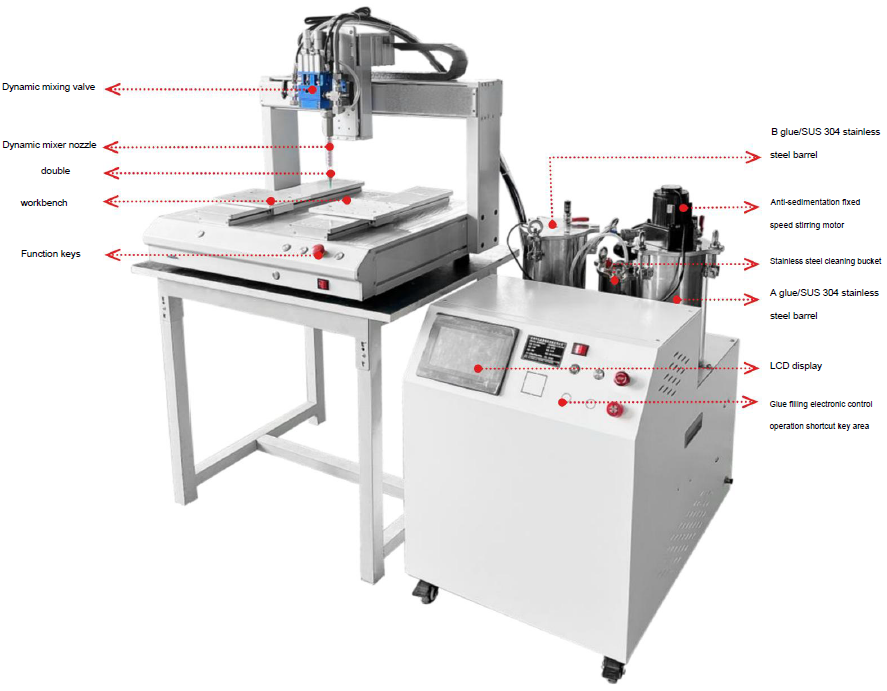

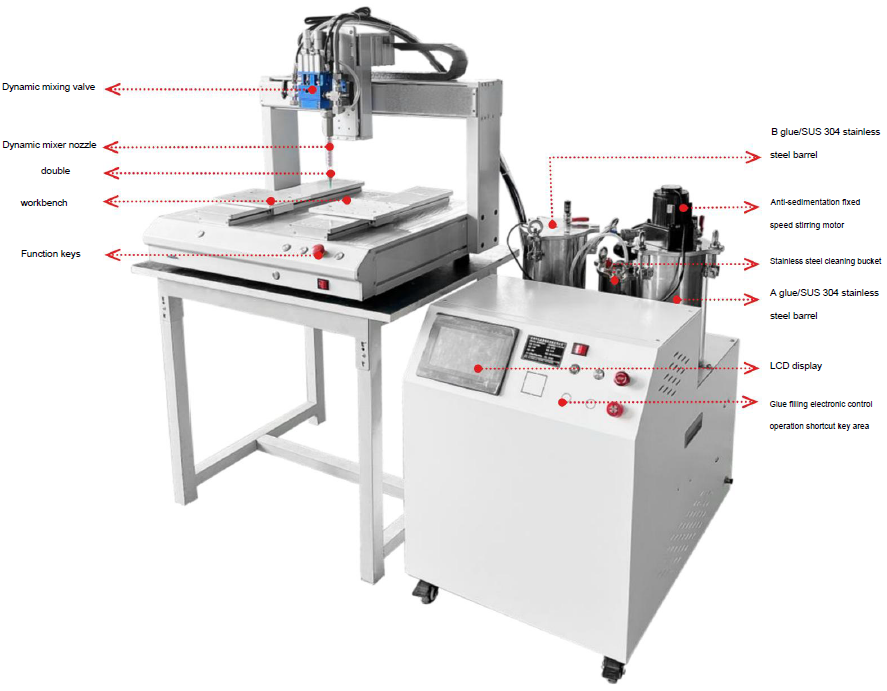

Structure :

Parameter :

- Effective itinerary:

- X=500mm Y1 /Y2=300mm Z=100mm

- A barrel (10L SUS304 stainless steel barrel):

- 10L/5L optional, constant temperature heating + constant speed anti-sedimentation stirring + lack of material alarm + manual feeding function optional

- B barrel ( 5L SUS304 stainless steel barrel)

- 10L/5L optional, constant temperature heating + constant speed anti-sedimentation stirring + lack of material alarm + manual feeding function optional

- C barrel (2L SUS304 stainless steel cleaning barrel):

- Precision screw metering pump + precision gear metering pump + brushless dynamic mixing and stirring glue + fully automatic cleaning (the pump configuration is selected according to the properties and amount of glue)

Overall dimensions:

- Desktop machine: 716mm*588mm*570mm

- Glue dispenser: 520mm*800mm*900mm

More detail about SEM Equipment Sdn. Bhd.

Malaysia

Malaysia