Description

Design-conscious HMI. Rear-Mount Model with Flat Mounting in the GP4000 Series lineup.

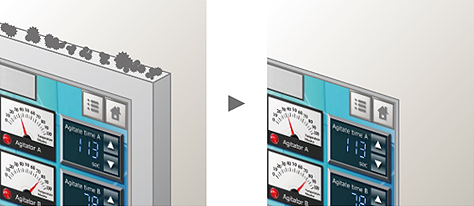

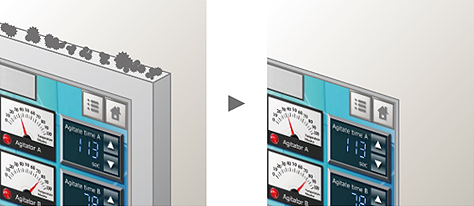

GP4000R Series can fit in with any equipment design because its bezel cannot be seen on a control panel. Flat mounting has the benefit of preventing the accumulation of dust and mold, and even allows the display to be used in medical equipment, food manufacturing equipment and other devices used in environments where hygiene is important.

Features:

A. Smart Display

1. Flat Mounting HMI, Integrates into Machine Design

- GP4000 Series Rear-mount Model is available for 12.1 in., 10.4 in., 7.5 in. and 5.7 in.

2. Maintain Hygiene of Display Area (Flat mount only)

2. Maintain Hygiene of Display Area (Flat mount only)

- Crates a flat, SEAMLESS display area to prevent accumulation of mold and dust, and to maintain a hygienic environment. Protective structure performance equivalent to IP67F can be expected.

- *By affixing an overlay (optional) to a console made from a specified material or a surface-treated console. For details, please refer to the Hardware manual.

3. Satisfies your desire to design

3. Satisfies your desire to design

The customized overlay satisfies your design needs such as color, size, customized key sheet, anti-glare surface, and so on.

- Blue overlay instead of a usual one

- Entire overlay including sheet keys

- Non-square overlay

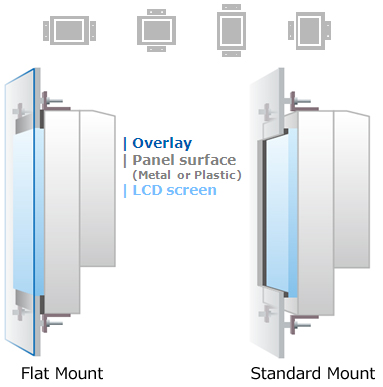

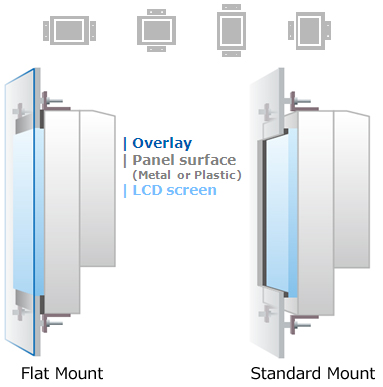

4. Choose from Mounting Patterns

4. Choose from Mounting Patterns

- Screen and bracket position selectable.

- Standard mount: The GP unit's screen is fixed within the inside of the panel or resin boss-molded product.

- Flat mount: The GP unit's screen is fixed to the same surface of the panel or resin boss-molded product. An overlay is required for flat mount.

5. Powerful TFT LCD expression in 65,536 colors

5. Powerful TFT LCD expression in 65,536 colors

- All models employ 65,536-color TFT LCDs. Improved visibility enhances operability and security.

6. Realistic 3D parts that look just like the real thing

6. Realistic 3D parts that look just like the real thing

- Add realistic three-dimensional graphical parts and easily create easy-to-identify screens with high added value. Realize expressive operation screens.

7. Customizable Start Screen

7. Customizable Start Screen

- Display registered image such as your company name or product logo as a splash screen during start-up.

8. Improved Start-up Speed

8. Improved Start-up Speed

Design and debugging work can be performed efficiently.

9. Many pre-configured sample screen for immediate use

A variety of ready-made sample parts are available for download. Sample parts can be used immediately after download, which lets you significantly reduce time spent on screen design.

B. Smart Connection

1. Monitoring Anywhere of Large/Long Equipment

- Using the remote monitoring and operation functions, actions that previously required multiple staff for a large-sized machine or long-distance application can be easily accomplished by fewer operators.

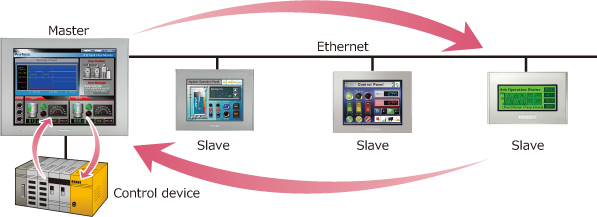

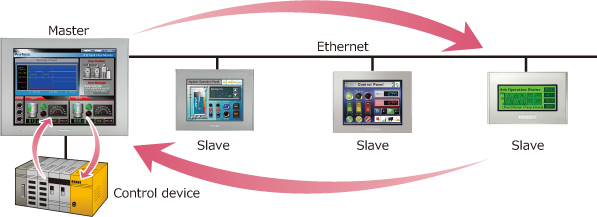

2. Ethernet Multi-Link function

- The Ethernet Multi-Link function allows you to easily add a GP as a sub-display to the facility without changing any settings of the control device.

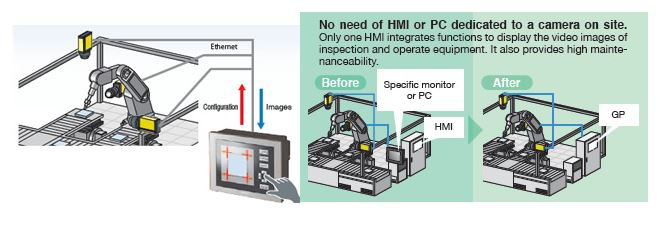

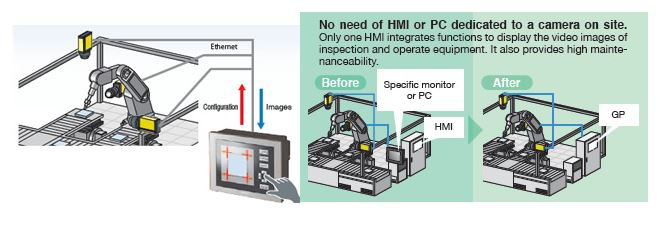

3. Use Video for On-Site Adjustments with COGNEX In-Sight vision system communication driver

3. Use Video for On-Site Adjustments with COGNEX In-Sight vision system communication driver

- In combination with a COGNEX In-Sight vision system,the settings can be changed when watching images from the cameras on a GP unit on site.

4. Supports Siemens PLC's tag import function

4. Supports Siemens PLC's tag import function

As the tag information of STEP7 Project Files created by Siemens PLC can be imported to GP-Pro EX screen data, you can reduce the man-hours for screen creation.

C. Smart Information

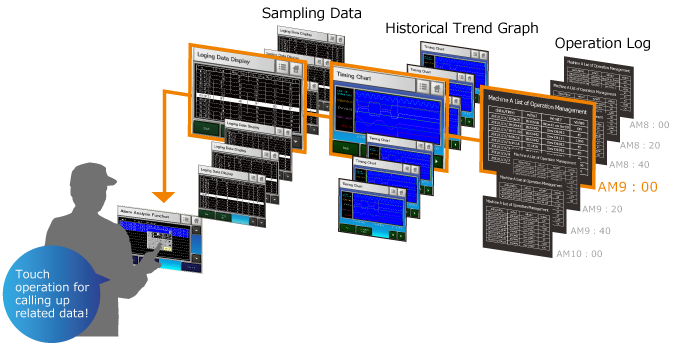

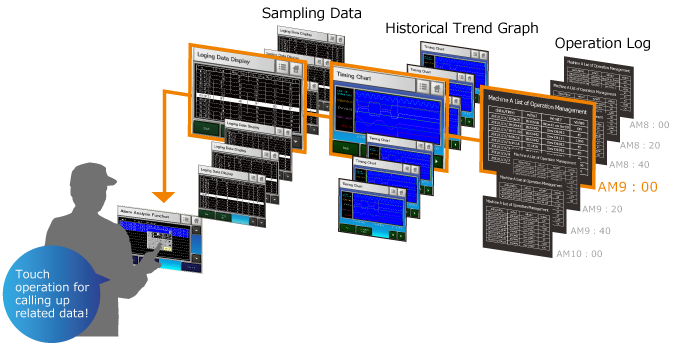

1. Alarm Analysis function

- When an error occurs, an operator can easily seek and check the condition on-site, just by touching the alarm message to call up various error-related data in chronological order. An alarm analysis screen with timing chart of alarm-related device addresses can be simply configured only through a few steps on GP-Pro EX software for easy troubleshooting, debugging and/or design changes of production equipment to reduce downtime for enhanced productivity.

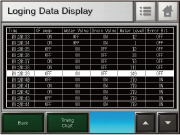

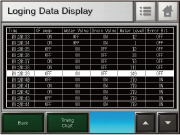

2. Sampling Data - Collecting various data during production

2. Sampling Data - Collecting various data during production

- Temperature, voltage, and other desired address values can be stored in the GP. Data and times can be confirmed on the sampling display.

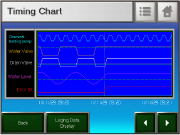

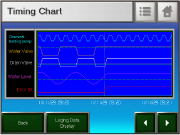

3. Historical Trend Graph - Displaying data in an easy-to-see graph

3. Historical Trend Graph - Displaying data in an easy-to-see graph

- The change in the collected data over time is displayed in an easy-to-understand form with a graph. The graph can be traced back to see the past data.

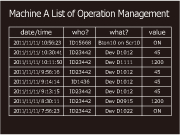

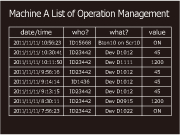

4. Operation Log - Recording the operator's operation

4. Operation Log - Recording the operator's operation

- Operations are saved to a log, so you can see who did what, and when. The log can also be used for a trend analysis of erroneous operation of operators.

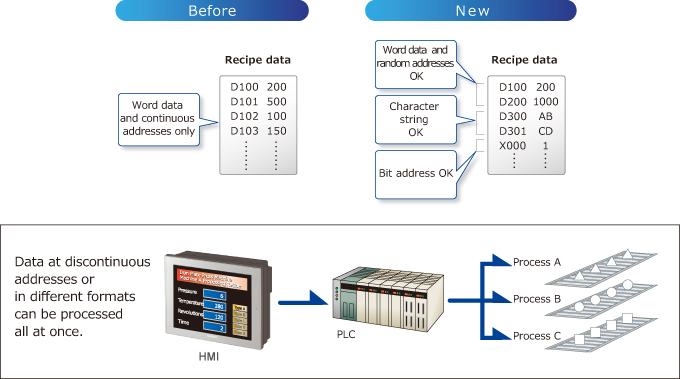

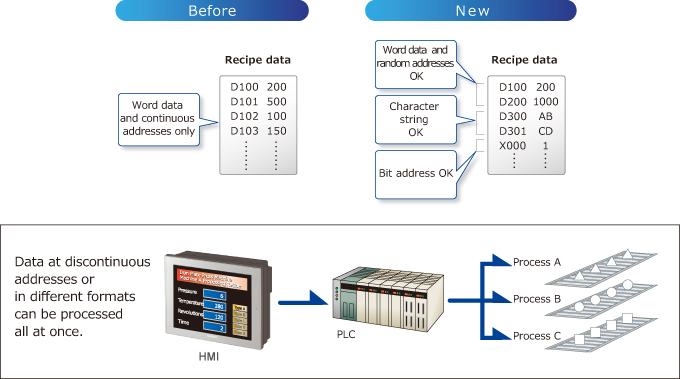

5. Enhanced Recipe function

5. Enhanced Recipe function

- With the conventional recipe function, all recipe data must be stored at continuous addresses. The new recipe function allows writing random addresses and multiple data formats as a recipe.

6. CSV data transfer function

6. CSV data transfer function

Since the CSV data stored in the USB memory/SD card can be edited, the recipe data can easily be carried for performing updates on-site. The alarm message can be easily changed with CSV files only.

7. Internal Logic Program - Program with a familiar ladder language

7. Internal Logic Program - Program with a familiar ladder language

- Screens and logic programming can be edited with the same software, so editing between parts and logic elements can be performed via drag and drop.

- Reduces PLC operation and program maintenance load.

- The online editing function allows you to make program changes on a computer during operation.

8. D-Script - Create unique macro program for user-customized data process and functions

8. D-Script - Create unique macro program for user-customized data process and functions

- Configure these settings based on trigger conditions including "Continuous Action", "Timer Bit Change", and "Condition Satisfied". Many functions are also provided including search (search and replace strings in the script) and debug functions (display messages and addresses on the unit).

D-Scripts created with GP-PRO/PBIII can be used unmodified so replacement is a breeze.

9. Pro-Server EX

9. Pro-Server EX

- Collect information of operation progress on a PC via Ethernet network. Download operating instructions, such as recipes, from an office PC to a GP.

10. GP-Viewer EX

- The screen of theHMI on the site can be monitored from a PC at a remote location.

11. Web Server

- Acquirable devices or alarms in the GP on the site can be monitored with a browser.

12. FTP-Server

- The content of a USB memory or SD card attached to the GP on the site can be interchanged from a remote location.

13. RPA (Remote PC Access) *Ver 4.09.400 or later is not supported.

- The work procedure document stored in a PC in an office can be displayed on the GP. This is effective to reduce procedural errors or other mistakes.

D. Smart Installation

1. Equipped with a user-replaceable battery

- Makes maintenance simple, even for equipment that is used for extended periods of time.

- Lets you save data even when using equipment that is left unpowered for long periods of time, giving peace of mind.

- It is recommended that batteries are replaced every 5 years. Batteries can be purchased as maintenance items.

2. Consistent direction of cabling

- Thanks to a consistent connection direction for cables and other interfaces, routing of wiring is now simpler than ever.

3. Easy to change the display screen

- The display screen can be changed by using a USB flash memory or SD card, without the need for a software license.

- The screen maintenance can be done without bringing a PC to a production site.

- A person in charge does not have to operate a PC, such as when manufacturing the multiple units of the same equipment.

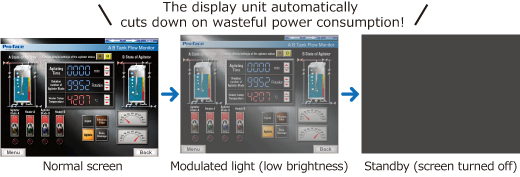

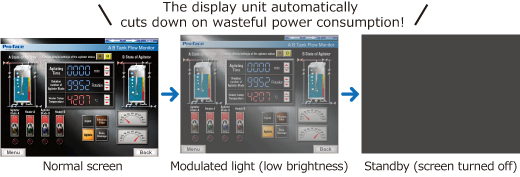

4. Energy Saving - Standard equipped with LED backlight LCD + Lighting adjustment

- Energy-saving capabilities have been greatly improved. The GP4000 Series contributes to reducing on-site power consumption in a variety of ways including an on-board LED backlight in all models, and a lighting adjustment function used to decrease and eventually stand-by the display after being idle for a set period of time.

More detail about POWER DRIVE TECHNOLOGY SDN. BHD.