Description

Flagship Model of HMI for extensive use of information

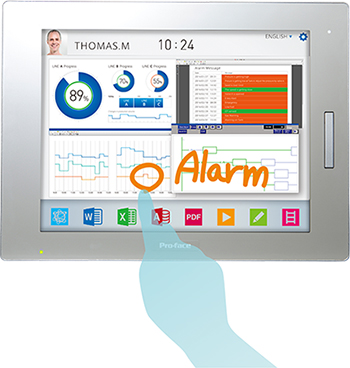

How can you fully utilize only the information you need from scattered big data? SP5000 Series provides Smart Portal, a window that optimally displays information in response to a demand for increasingly sophisticated

information utilization as a new solution.

Features:

A. Valuable information in the right format

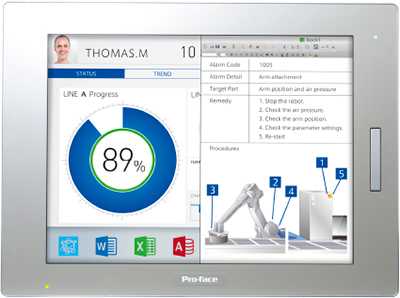

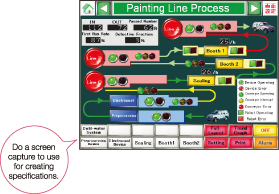

1. Use Windows Applications via the On-Site Smart Portal

- SP5000 stores the documents you always use to the Smart Portal so that you can utilize them. Use manuals and troubleshooting guides that you already have as they are, without special instruction screens, to drastically cut design man-hours.

2. Utilize Your Own Applications

2. Utilize Your Own Applications

- You can use your own applications on the on-site Smart Portal.

3. Dedicated launcher

3. Dedicated launcher

- The dedicated launcher which is Pro-face original tool also makes application startup easier and more flexible.

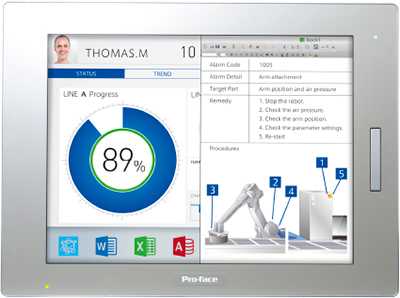

4. Use On-Site Smart Portal to Perform Maintenance

4. Use On-Site Smart Portal to Perform Maintenance

- SP5000 can store maintenance and a variety of other tools. To perform maintenance, you used to have to bring a PC, open the control panel, look for the controller and connect a cable. Lack of space to even put the computer down meant that you frequently debugged with the PC on your lap. With SP5000, the HMI usually used as a control terminal serves the role of a PC at times to reduce workload during maintenance. You can also combine with the Pro-face Remote HMI to remotely monitor and control applications. To monitor using a tablet, for example, you can start the HMI screen with a PLC program tool.

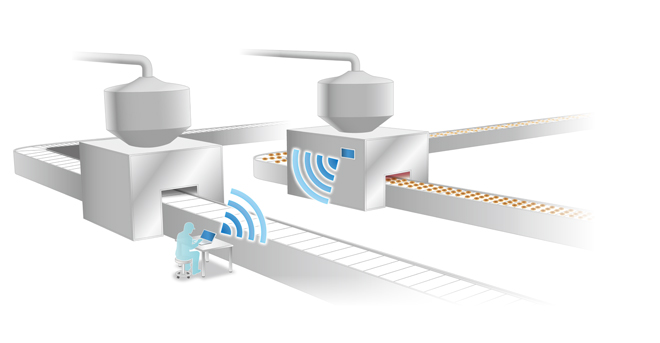

5. Improved debugging efficiency

5. Improved debugging efficiency

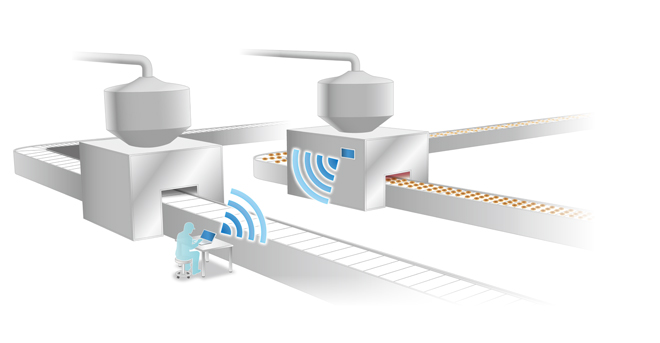

- With the SP5000 series wireless LAN model, easily check device status anywhere without cables.

6. Use Even More Information in High-Speed Processing

6. Use Even More Information in High-Speed Processing

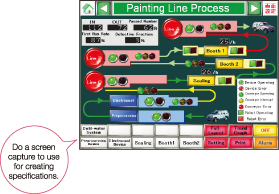

- CPU capacity is 8 times greater than our existing HMI. Renders a visually pleasing display even if the amount of information to display on the screen increases. Motion and other position information, for example, is displayed at high speeds and large-quantity recipes are processed at high speeds. Animation is used to express equipment status realistically, while flowcharts and other detailed information also display clearly.

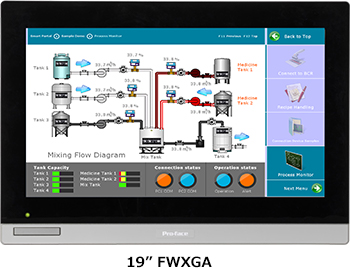

7. Crisp display

7. Crisp display

- Since up to 16 million colors are available for display, you can create a beautifully visible screen with pictures.

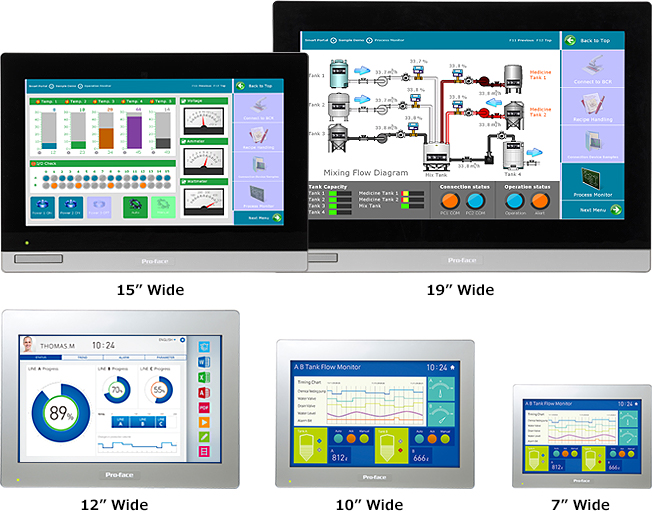

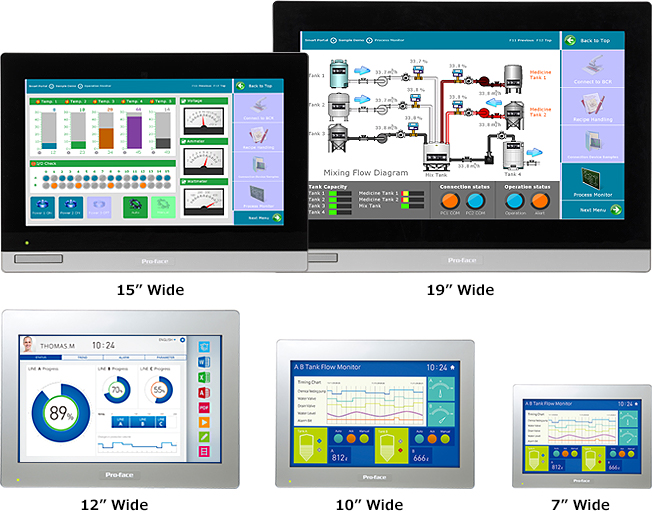

8. Wide display

8. Wide display

- The 16:9-wide screen allows you to use the right and/or left space for a landscape-oriented graph as well as a menu in order to access lots of information.

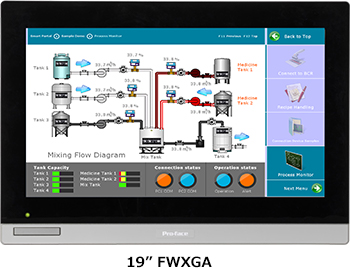

9. Large display

9. Large display

- The largest 19-inch (1366 x 768) of SP5000 series can show lots of information on a screen. A wide selection of sizes from 7 to 19-inch display is available.

10. Tablet-based on-demand HMI

10. Tablet-based on-demand HMI

- See status of equipment or devices in the right place at the right time.

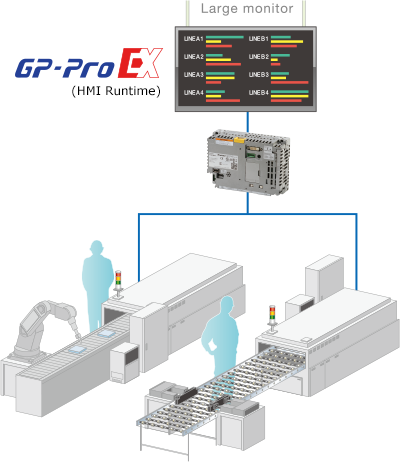

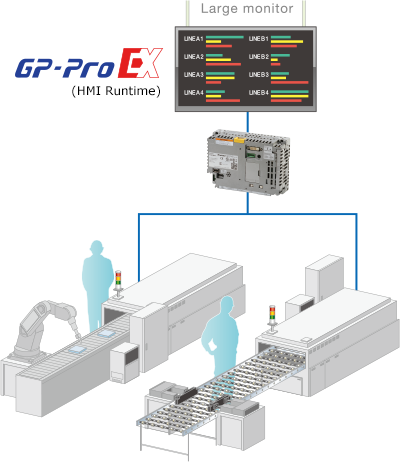

11. HMI for ANDON (Large-sized monitor)

11. HMI for ANDON (Large-sized monitor)

- Optimize work by sharing production status.

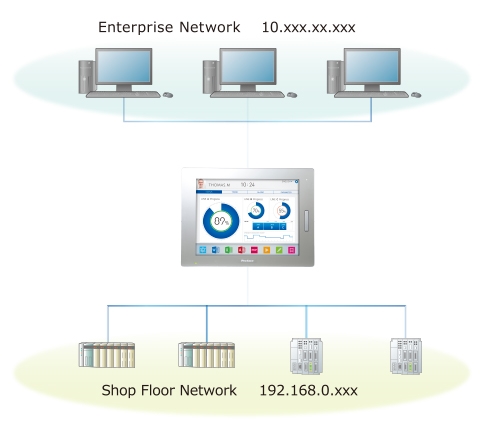

B. Bring your factory closer to your office

B. Bring your factory closer to your office

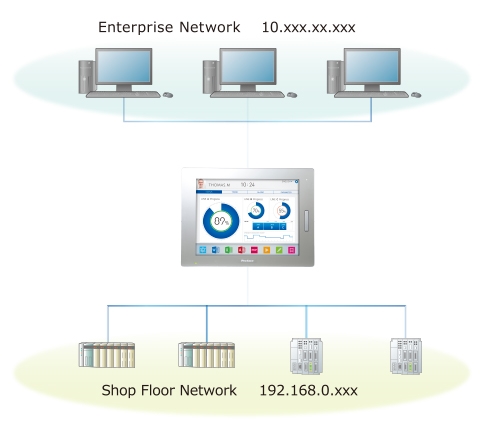

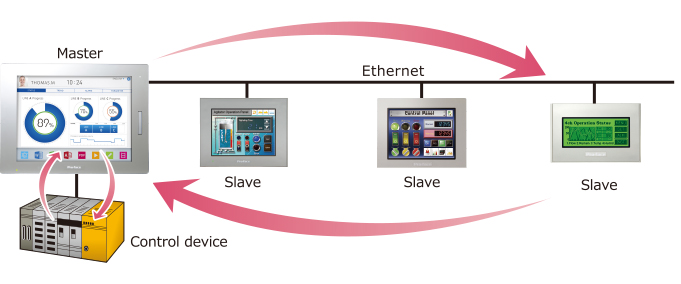

1. Connect Different Networks after Securing Safety

- Mounted with 2 Ethernet ports, SP5000 makes network segmentation simple. Different IP addresses can be configured for each port, enabling safety to be secured before construction of the network system. For example, installing SP5000 between office and factory networks helps utilization of both the big data continuously increasing at the production site as control devices get faster, and the continuously increasing big data on the office side of production control.

2. Network Modularity

2. Network Modularity

- Until now, only 1 IP address could be set to our existing HMI, and it took equipment manufacturers a lot of time to change all device IP addresses on various tools at the time of delivery. SP5000 allows you to eliminate reconfiguration time at delivery by allowing 2 IP addresses to be configured from the start.

3. Reduce cable-wiring time

- Easily modify production lines. The SP5000 series wireless LAN model allows you to add devices without any changes to existing system.

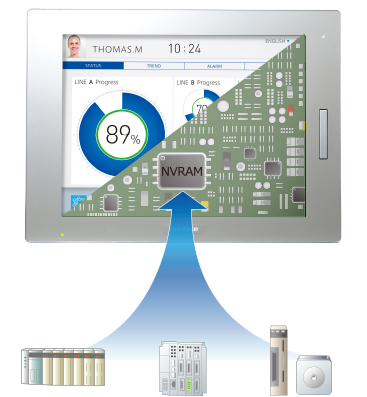

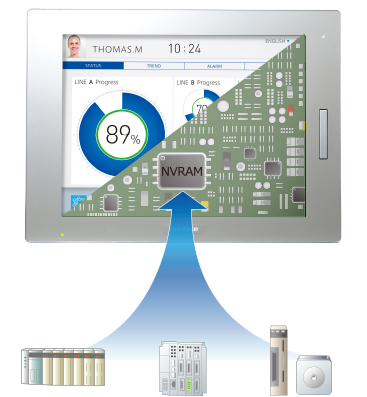

4. Protects system even during a sudden power interruption

- Computers are useful for general-purpose applications, but needed an uninterruptible power supply or similar measures in case of a sudden power interruption. SP5000 is fitted with a data backup NVRAM to protect histrical data in the event of a sudden power interruption. Power can be turned off in the same way as the normal HMI even without executing shutdown processes like a computer.

5. Merge data from different devices

5. Merge data from different devices

- Unify protocols and collect data efficiently.

C. Simple to use - any time, any place

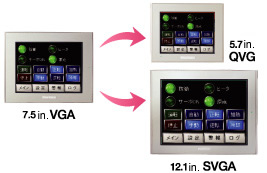

1. Supports Flexible Designs

- SP5000’s module structure makes it easy to change display size according to a use scenario and customer demands. No configuration changes to the project file are required, and display boxes can be easily converted. Premium Display also supports automatic screen scaling.

2. Select a front panel color that suits on-site equipment

2. Select a front panel color that suits on-site equipment

- Choose a color for the front panel suitable to an installation environment and equipment colors.

3. Sound audio alarms on external speakers

3. Sound audio alarms on external speakers

- SP5000 is equipped with an auxiliary interface for audio alarm output to connected speakers.

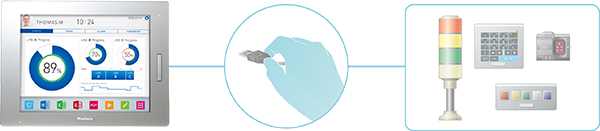

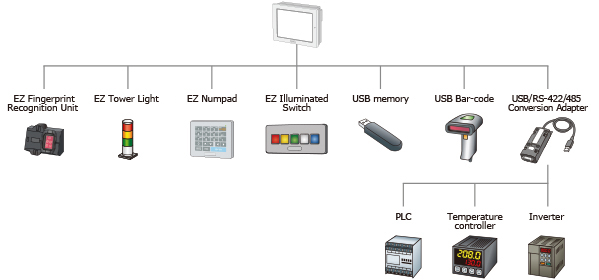

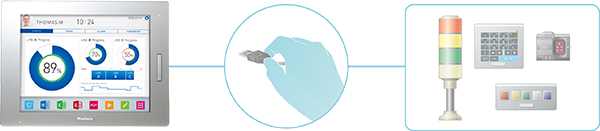

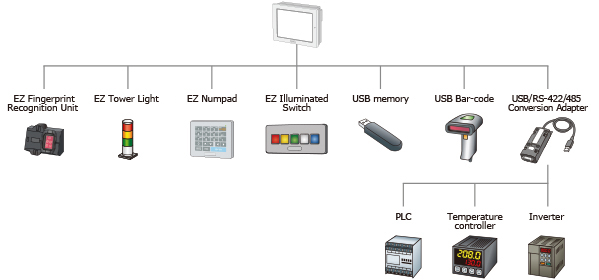

4. Expand functions with a single USB cable

- Supports the convenient EZ Series option, which allows simple expansion of functionality by connecting a USB cable to SP5000.

5. Eliminate maintenance tasks and costs

5. Eliminate maintenance tasks and costs

- Modular construction and storage mounts included for the main unit make maintenance easy to perform with SP5000 in a short amount of time. For example, by replacing the display unit alone or just the box, you can eliminate the costs for spare parts. Also, since box replacement entails simply replacing the data media (SD/CFast), anyone can do the job.

6. USB Front Interface

- For Premium Display, USB Interface is located on the front side. It’s easy to take data and do maintenance.

7. Integrated Mounting Bracket

7. Integrated Mounting Bracket

- Integrated mounting bracket does away with the need for separate optional accessories every time setup or maintenance work is conducted.

8. Easily bring wireless environment with a display

8. Easily bring wireless environment with a display

- The SP5000 series wireless LAN model centralizes information management.

9. Use in a variety of locations around the world

- Mounted with a number of convenient functions for use in any place around the globe. Functional at up to 60 degrees, SP5000 can be used in high-temperature regions. Delivery overseas runs smoothly because screen items can be set to the local time zone. High memory capacity supports a communicable screen using images and image fonts, and enables multiple language information to be stored in a single data set.

10. Suitable for use in scenarios with sanitation requirements

- SP5000’s support of IP65F / IP66F / IP67F and ability to withstand high-pressure washing makes it suitable for use in scenarios with sanitation requirements.

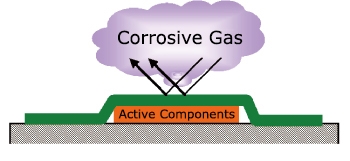

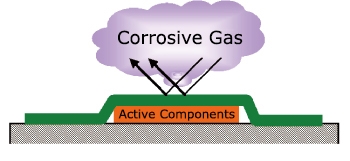

11. Protection from Chemical and Oil mist

11. Protection from Chemical and Oil mist

- The Environment Cover reduces machine troubles caused by corrosion from chemical and oil mist, and brings lower maintenance costs.

12. Simply covered

12. Simply covered

- Easily attach and remove the Environment Cover without special tools.

- The UV Protection Sheet that protects a touch panel display from pollution and UV is also available.

13. Peace of mind in a harsh environment. Coated models feature more protection from corrosion.

13. Peace of mind in a harsh environment. Coated models feature more protection from corrosion.

- Extended product lifetime for use in harsh environments compared to uncoated products. Corrosion resistance is also improved.

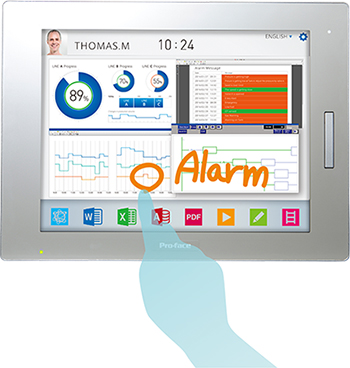

14. Use handwritten memos for task handover

14. Use handwritten memos for task handover

- SP5000 is fitted with a multi-touch panel where you can leave handwritten memos to share information when handing a task over to someone else at the site.

15. Screen display brightness can be automatically adjusted

15. Screen display brightness can be automatically adjusted

- For Premium Display, a brightness sensor detects surrounding luminance to allow automatic adjustment of screen brightness. Eliminates excess electricity and contributes to lower energy use.

16. Capable of operation that prevents misoperation

16. Capable of operation that prevents misoperation

- SP5000 supports input via pressing two points to support operations such as use of interlock to prevent on-site operator errors.

B. Interface Basic Features

B. Interface Basic Features

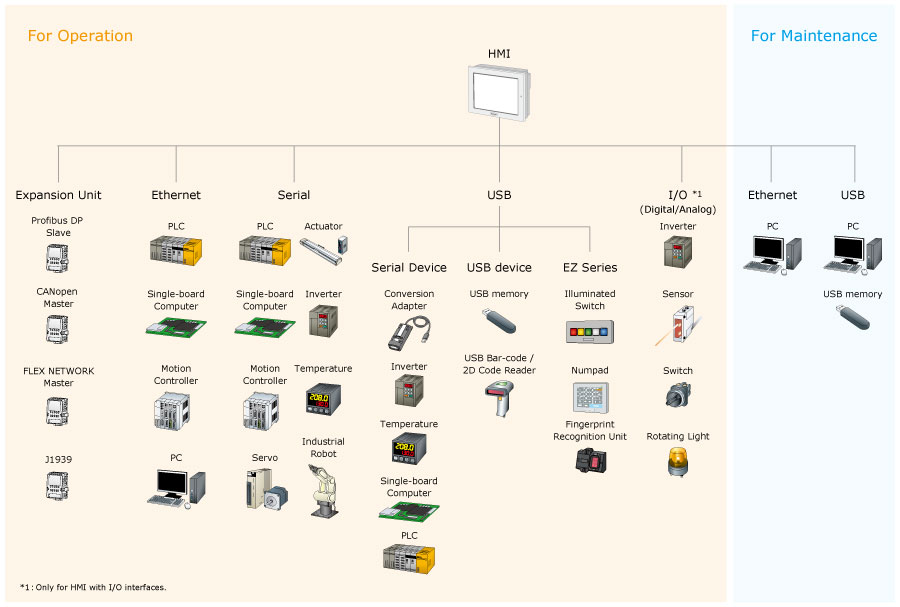

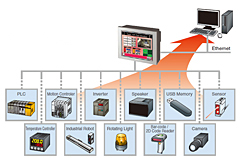

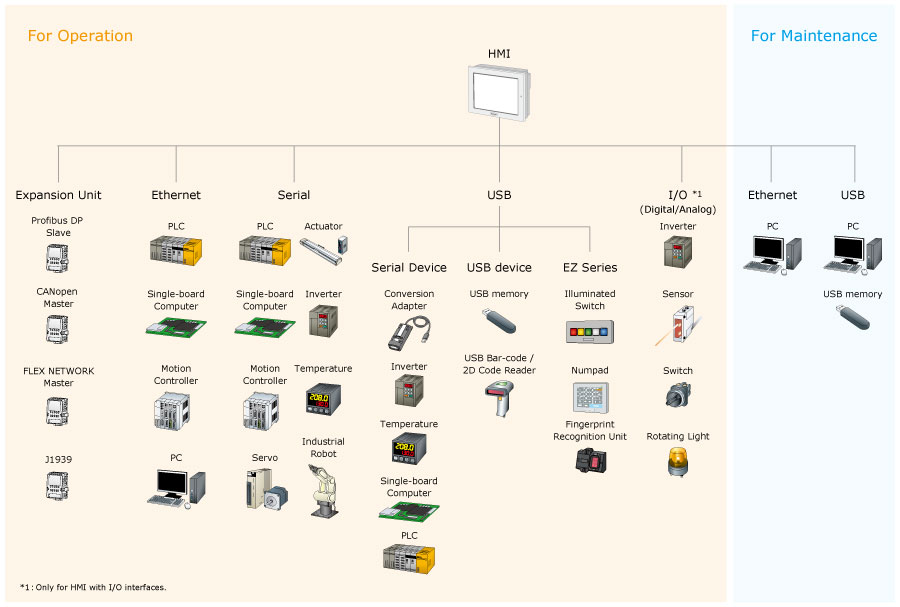

1. Connectivity

- Connect directly to a wide range of devices. From IT network to I/O, connect and visualize with a single unit.

2. Connect to a wide range of control equipment

2. Connect to a wide range of control equipment

- Support connection with a wide range of industrial controllers including PLCs, motion controllers, robots, and other devices. A USB to RS-422/485 conversion adapter can be used to allow connection to a wide range of control equipment including temperature controllers, inverters, and PLCs.

For more information on supported equipment, please refer to this list.

3. Use Video for On-Site Adjustments with COGNEX In-Sight vision system communication driver

3. Use Video for On-Site Adjustments with COGNEX In-Sight vision system communication driver

In combination with a COGNEX In-Sight vision system,the settings can be changed when watching images from the cameras on a display unit on site.

- A communication driver supports In-Sight Micro series and In-Sight 5000 series.

- You can view video images from up to 3 cameras on a single screen. Up to 16 cameras can be connected to GP.Display position (X/Y), exposure time, focus, lighting and brightness can be adjusted on GP.

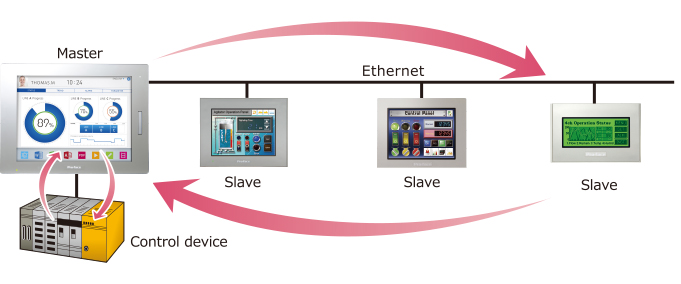

4. Ethernet Multi-Link function

- The Ethernet Multi-Link function allows you to easily add a display unit as a sub-display to the facility without changing any settings of the control device.

5. Easily connect multiple USB devices

5. Easily connect multiple USB devices

A controller with serial interface, EZ Series accessory unit, bar code reader, and USB flash drive can be easily connected to the display unit.

- EZ Fingerprint Recognition Unit also requires power supply cable.

- Except for serial devices via USB-RS422/485 conversion adapter, multiple devices of the same model cannot be connected.

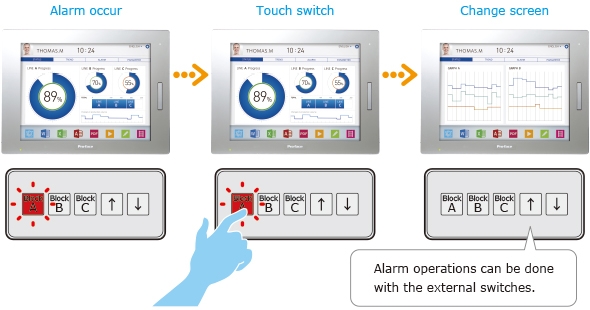

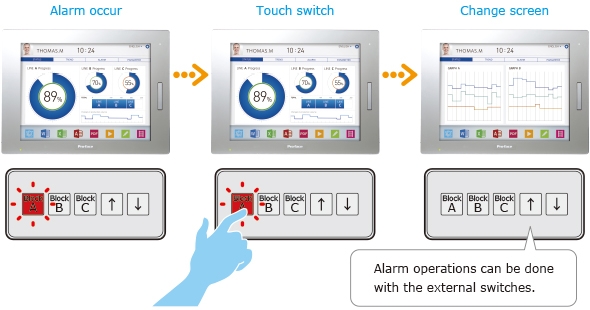

6. Indicate status of not displayed screens for each line or machine

6. Indicate status of not displayed screens for each line or machine

- EZ Illuminated Switch can be set to indicate alarm status with different colors according to current status. All alarm histories in the display unit can be checked and operated on one EZ Illuminated Switch. You can check alarm status even when operating another screen or when the display unit is in standby mode.

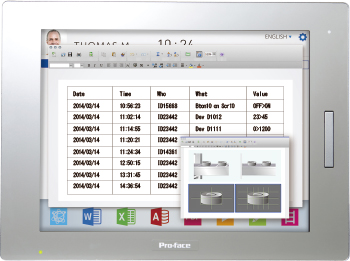

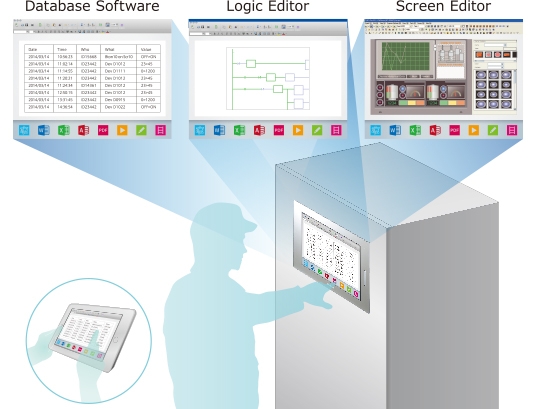

7. Achieve goals promptly and boost system performance easily

7. Achieve goals promptly and boost system performance easily

- GP-Pro EX delivers a range of advanced functions that allow you to respond promptly to the needs of the ever-evolving manufacturing worksite. It provides comprehensive programming and log analysis functions to aid the development of more sophisticated systems.

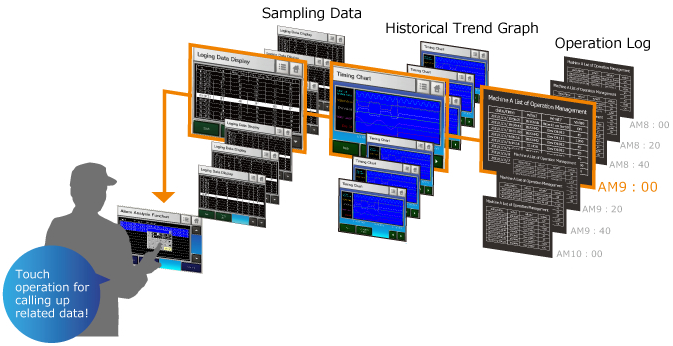

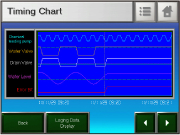

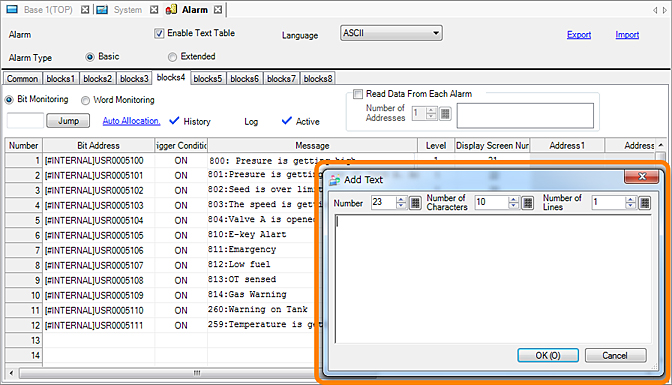

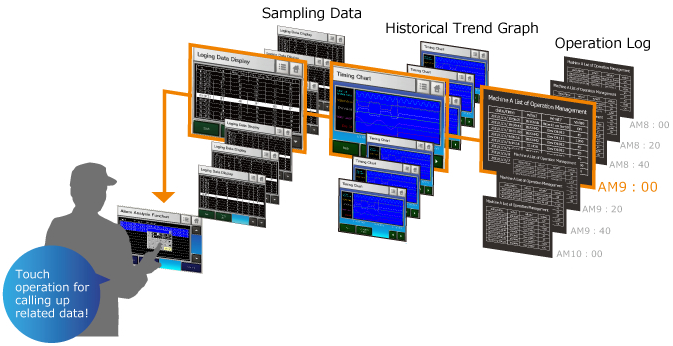

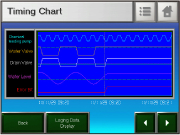

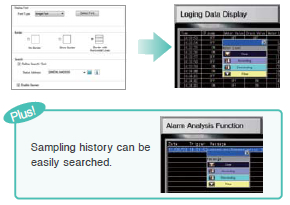

8. Production loss can be minimized with "Alarm Analysis" function

8. Production loss can be minimized with "Alarm Analysis" function

- When an error occurs, an operator can easily seek and check the condition on-site, just by touching the alarm message to call up various error-related data in chronological order. An alarm analysis screen with timing chart of alarm-related device addresses can be simply configured only through a few steps on GP-Pro EX software for easy troubleshooting, debugging and/or design changes of production equipment to reduce downtime for enhanced productivity.

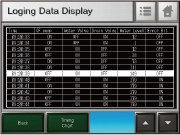

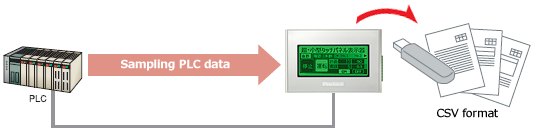

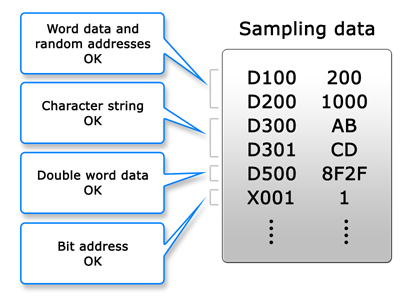

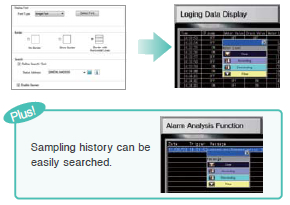

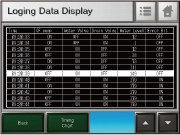

9. Sampling Data - Collecting various data during production

9. Sampling Data - Collecting various data during production

- Temperature, voltage, and other desired address values can be stored in the memory. Data and times can be confirmed on the sampling display.

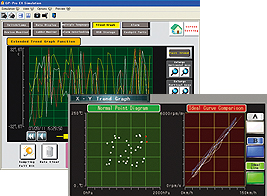

10. Historical Trend Graph - Displaying data in an easy-to-see graph

10. Historical Trend Graph - Displaying data in an easy-to-see graph

- The change in the collected data over time is displayed in an easy-to-understand form with a graph. The graph can be traced back to see the past data.

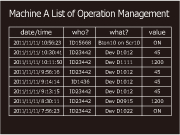

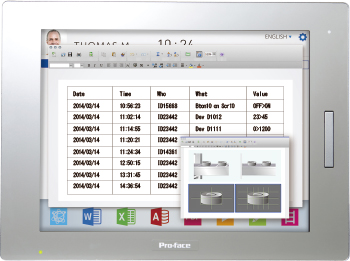

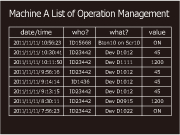

11. Operation Log - Recording the operator's operation

11. Operation Log - Recording the operator's operation

- Operations are saved to a log, so you can see who did what, and when. The log can also be used for a trend analysis of erroneous operation of operators.

12. Line setting changes can be performed smoothly with "Enhanced Recipe function"

12. Line setting changes can be performed smoothly with "Enhanced Recipe function"

With the conventional recipe function, all recipe data must be stored at continuous addresses. The new recipe function allows writing random addresses and multiple data formats as a recipe.

- Data at discontinuous addresses or in different formats can be processed all at once. (* GP-4*01TW and GP-4401WW don't support the sort/ search feature.)

13. Alarm History Banner Display

13. Alarm History Banner Display

- Long alarm messages are automatically scrolled and displayed so their details can be checked.

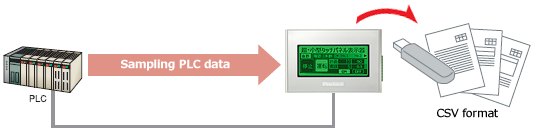

14. Output of sampling data in a CSV format

14. Output of sampling data in a CSV format

- The data (sampling data) sampled by sampling feature is saved in CSV format on an USB storage device. This improves the efficiency of preparing daily and monthly reports.

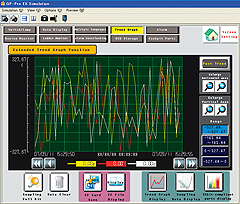

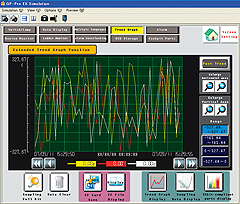

15. Analyze problem causes easily with historical trend graphs

15. Analyze problem causes easily with historical trend graphs

- GP-Pro EX provides the ability to display error logs in graph form, making it easy to analyze the causes of a problem. Supported features include enlarged/reduced display, auxiliary line display for upper and lower limits, and XY scatter graphs.

15. Manage operation log data

15. Manage operation log data

- GP-Pro EX lets you obtain operation logs for each operator on a part-by-part basis. This gives you the ability to convert just the sections you need into data for easy management.

16. Configure detailed security settings for each user

16. Configure detailed security settings for each user

- GP-Pro EX lets you configure detailed authorization settings by setting different passwords and security level IDs for each part.

17. Change security settings from an HMI during operation

- Password configuration, fingerprint authentication, and other security settings can be performed on a local display unit even while the machine is running.

18. "GP-Viewer EX" - View and operate a remote GP from an office PC

- View and operate on-site display unit on a remote PC via Ethernet to monitor on-site status.

19. "Web Server" - View the information of alarms and device addresses on a browser

19. "Web Server" - View the information of alarms and device addresses on a browser

- Remote monitoring and maintenance can be done from office viewing the information of alarms and device addresses on a browser. Additionally, alarm notifications can be sent in real-time through RSS feeds.

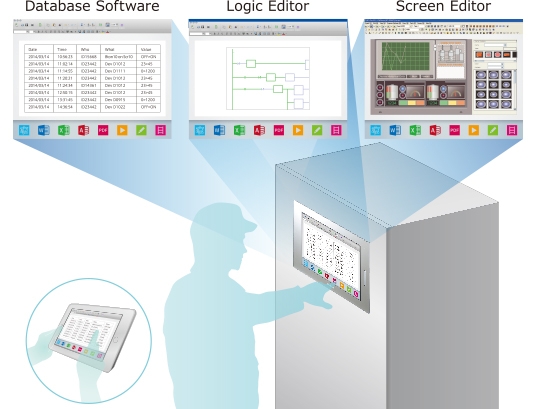

C. Easy Screen Creation

C. Easy Screen Creation

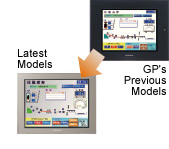

1. Leverage existing assets

- GP-Pro EX supports screens made using all models as far back as the original model GP510 Series.

- Data created in GP-PRO/PBIII for Windows or later versions can be converted instantly in Project Converter.

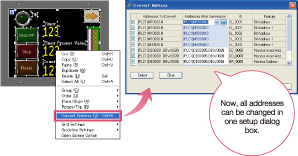

2. Convert entire projects with Project Converter

2. Convert entire projects with Project Converter

- GP-Pro EX supports screen data made using all models as far back as the original model GP510 Series. Upgrading to the latest models is a smooth process as GP-Pro EX's Project Converter can be used to directly convert data created with GP-PRO/PBIII for Windows or later versions.

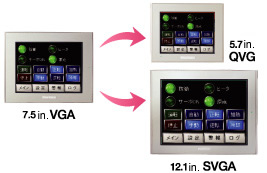

2. Change display sizes easily with Resolution Converter

2. Change display sizes easily with Resolution Converter

- GP-Pro EX's Resolution Converter automatically converts project files into different resolutions. This significantly reduces man-hours associated with changing display sizes.

3. Batch Part Converter can change all shapes on a screen at once to bring back old screens

3. Batch Part Converter can change all shapes on a screen at once to bring back old screens

- GP-Pro EX lets you batch convert parts of differing shapes. This makes it possible to easily renew images in project files made in the past.

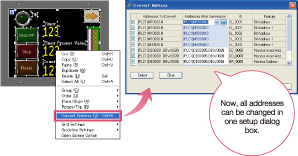

3. Create similar screens in next to no time using batch converting addresses of selected parts

3. Create similar screens in next to no time using batch converting addresses of selected parts

- With GP-Pro EX you can convert selected part addresses as a block. This gives you the ability to create similar screens quickly.

4. Sharing Images and Parts for using existing Parts and graphics you have created

4. Sharing Images and Parts for using existing Parts and graphics you have created

- Parts and graphics you have created can be registered as a package. Save the packages to a server to share them among designers.

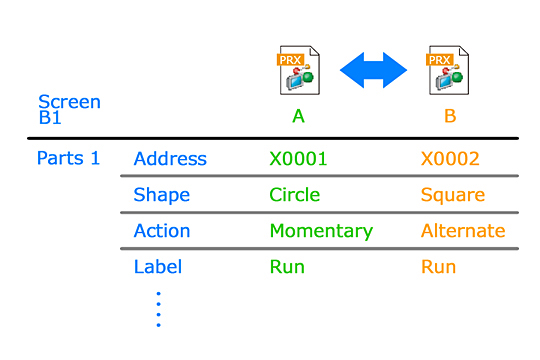

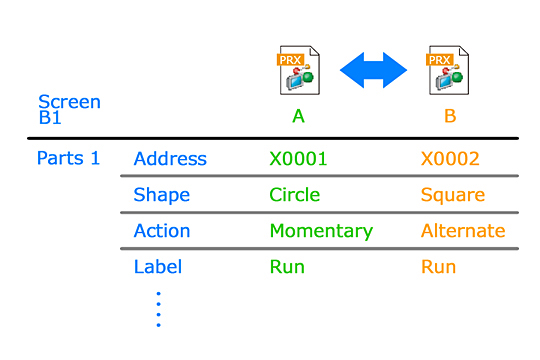

5. Quickly understand detailed differences between similar project files

5. Quickly understand detailed differences between similar project files

- Project Comparison Tool allows easy yet detailed comparison of two screen-project files for updating and modifying customer applications. Differences for each part attribute, alarm message, or setup item are displayed.

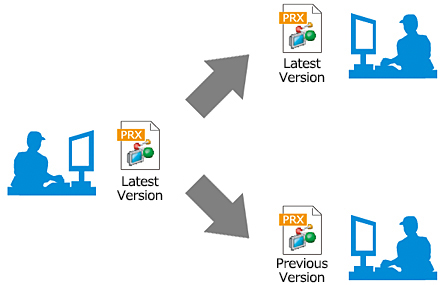

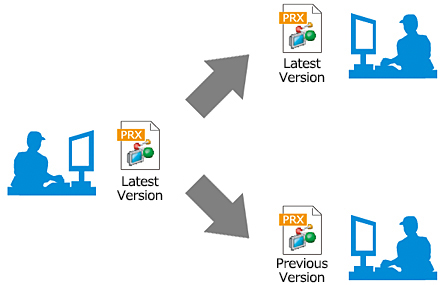

6. Multi-version File Format Support for Screen Project Files

6. Multi-version File Format Support for Screen Project Files

- Screen project files edited in the latest version of GP-Pro EX can also be saved in the previous version format to facilitate screen data handling among personnel with different responsibilities such as testing engineers, factory installation technicians, and maintenance engineers.

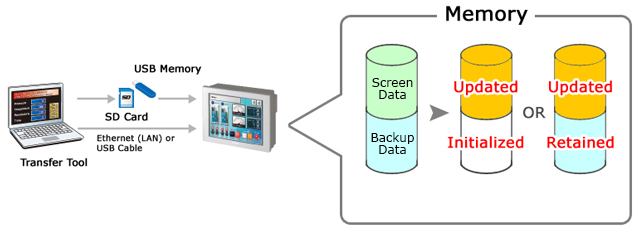

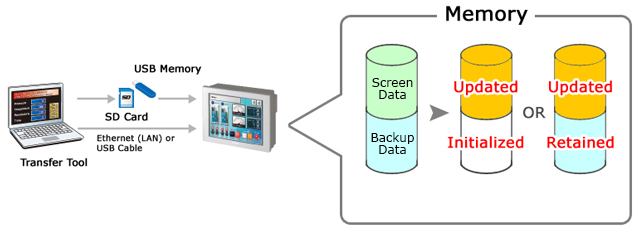

7. SRAM Data Retention during Screen Data Update

7. SRAM Data Retention during Screen Data Update

- You can select to reset or to retain saved variable data in SRAM upon updating screen data.

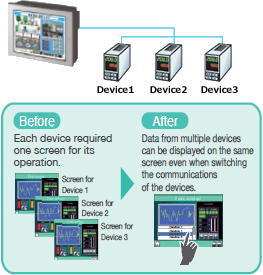

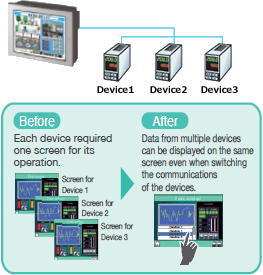

8. Indirect Device Setting – Only one screen can communicate with multiple devices

8. Indirect Device Setting – Only one screen can communicate with multiple devices

- Only one screen is required to communicate with multiple devices. It allows you to reduce time for screen design.

9. Anyone can design beautiful, realistic screens

9. Anyone can design beautiful, realistic screens

- GP-Pro EX has an extensive variety of functions for designing beautiful, realistic screens.

- Naturally, a wide range of free sample screens are also available. Pro-face's beautifully designed samples are produced with user-friendliness in mind and are sure to gain a solid reputation amongst worksite operators.

10. User Original Start Screen

10. User Original Start Screen

For Power Box, display a registered start screen (image) from when the power is turned on until when the initial base screen is displayed.

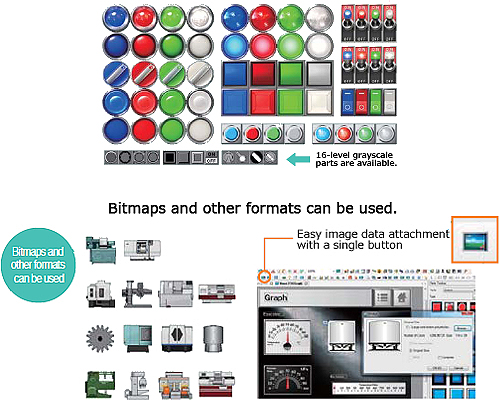

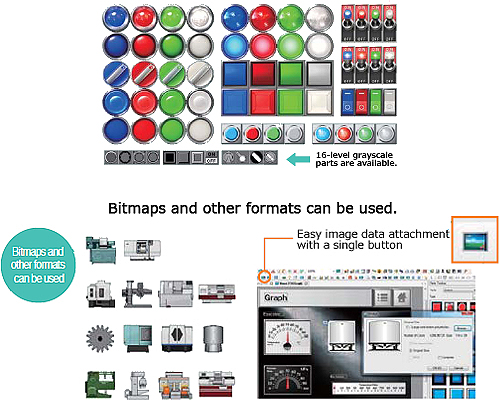

11. Realistic 3D parts that look just like the real thing

11. Realistic 3D parts that look just like the real thing

- Add three-dimensional graphical real parts and easily create easy-to-read screens with high added value.

12. Meters

- Production equipment measurements and temperatures are intuitively displayed.

13. Switches/Lamps

13. Switches/Lamps

- Can be visually checked like real switches and lamps. It increases the added value of your screens.

14. Add movement with animation feature to make parts even more realistic

14. Add movement with animation feature to make parts even more realistic

- GP-Pro EX has an animation feature that draws graphics and lets you move, rotate, or change the color of images. This makes it possible to quickly design screens with rich expression that move and change.

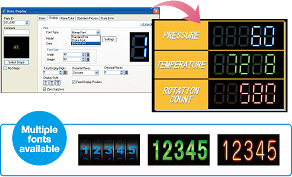

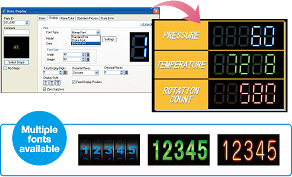

15. Display numerical data in style with bitmap fonts

- GP-Pro EX has a range of beautiful, easy-to-read 7-segment fonts for data display parts.A variety of other fonts are also available.

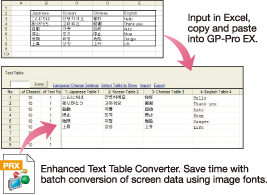

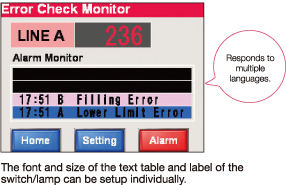

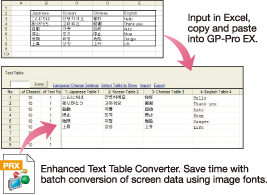

16. Use image fonts to expand design possibilities with Windows fonts

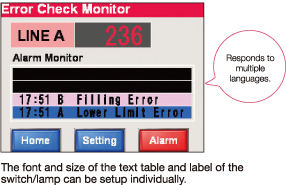

16. Use image fonts to expand design possibilities with Windows fonts

- GP-Pro EX lets you create stylish screens using Windows fonts. Multiple languages are supported and fonts can be applied to data displays, text tables, alarms and a variety of other functions.

17. Display/Hide parts saves development time

17. Display/Hide parts saves development time

- Control part visibility by device or operator. Save development time and reduce project file size. This can reduce man-hours since separate screens do not need to be created.

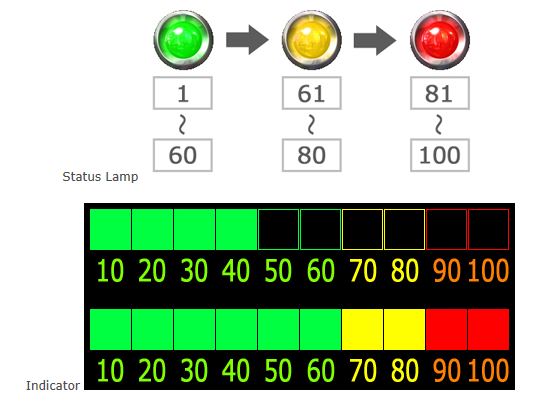

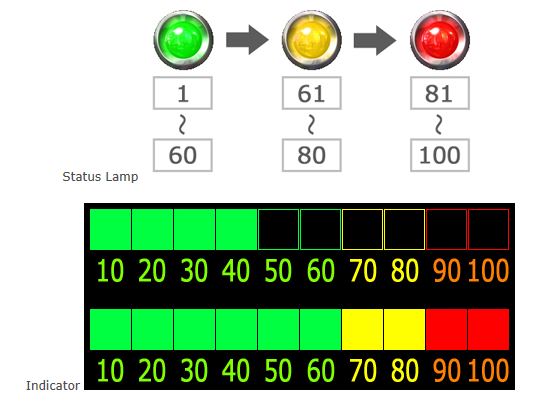

18. Word Data Range Setting on Lamp Display

18. Word Data Range Setting on Lamp Display

- Display status of a lamp can be set according to pre-configured data range.

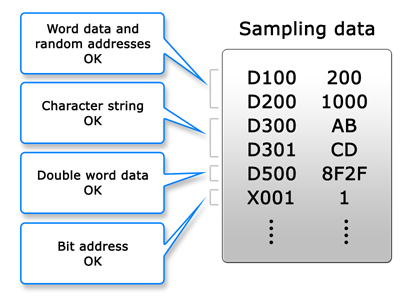

19. Sampling in different device formats

19. Sampling in different device formats

- Text, bits, and variables that could only be set for devices as numeric values can now be mixed. Connected devices + internal addresses can also be set.

20. Utilize Siemens PLC's tag and improve efficiency

20. Utilize Siemens PLC's tag and improve efficiency

- As the tag information of STEP7 Project Files created by Siemens PLC can be imported to GP-Pro EX screen data, you can reduce the man-hours for screen creation.

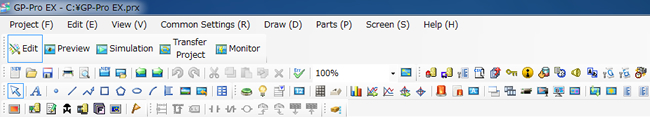

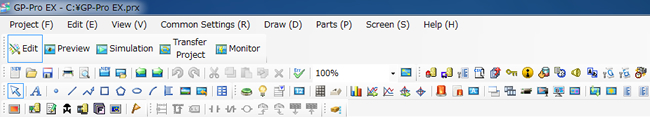

21. Much easier-to-understand icon design

- The icon design of GP-Pro EX is easier to understand. You can quickly find what you want from many icons and improve work efficiency.

22. Find the parts you want immediately Parts Toolbox

22. Find the parts you want immediately Parts Toolbox

- GP-Pro EX's Parts Toolbox lets you narrow quickly find the parts you need. You always know what parts you are using at any given moment, which makes screen design more efficient.

23. Headers and footers for immediate access to frequently used screens

23. Headers and footers for immediate access to frequently used screens

- GP-Pro EX lets you register screen elements that are frequently used at the top or bottom of a screen and call them up in a project.

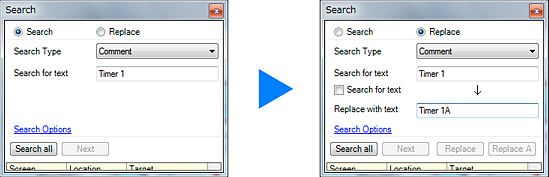

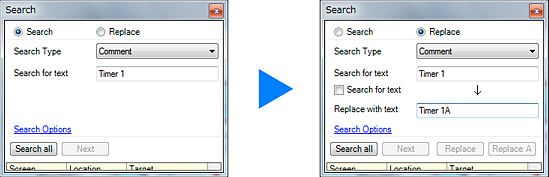

24. Text Search/Replace Function

24. Text Search/Replace Function

- It is now possible to search for or find and replace text data in screen projects.

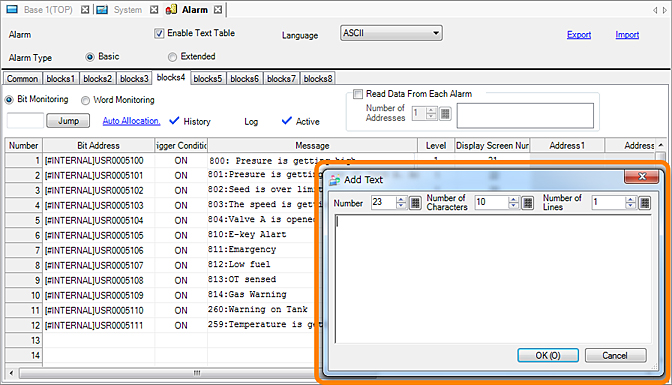

25. Direct alarm message input for multi-language setting

25. Direct alarm message input for multi-language setting

- You can register multi-language text to text tables in alarm settings for even more efficient screen editing.

26. Searching/sorting alarm and sampling history

26. Searching/sorting alarm and sampling history

- Easy ascending/descending sorting and conditional search using symbols such as =, > or < of Alarm Part and Sampling Display.

27. Text tables support multiple languages for use anywhere in the world

27. Text tables support multiple languages for use anywhere in the world

- GP-Pro EX makes it easy to change language settings. Creating multi-lingual projects is a breeze.

28. Programing function relieves PLC memory burden

28. Programing function relieves PLC memory burden

- GP-Pro EX supports logic programs, which let you create programs in a familiar ladder program format, and D-Script, a proprietary scripting language that offers similar functionality to sophisticated programming languages. This lowers the burden placed on the PLC and enables high-level screen design.

30. Logic Program - Program with a familiar ladder language

- Screens and logic programming can be edited with the same software, so editing between parts and logic elements can be performed via drag and drop. Controller addresses can be directly written, allowing you to reduce development time.

31. D-Script - Create programs with our unique simplified language

- Configure these settings based on trigger conditions including "Continuous Action", "Timer Bit Change", and "Condition Satisfied". Many functions are also provided including search (search and replace strings in the script) and debug functions (display messages and addresses on the unit).

32. D-Scripts created with GP-PRO/PBIII can be used unmodified so replacement is a breeze.

33. GP-Pro EX Simulation – A solid reputation for user-friendliness

- With GP-Pro EX you can simulate connection with a PLC on your PC, even if you don't have a display or PLC. The simulation function also supports Mitsubishi Electric PLCs.

More detail about POWER DRIVE TECHNOLOGY SDN. BHD.

More detail about POWER DRIVE TECHNOLOGY SDN. BHD.