The AirTac JSI Series Standard Cylinder is meticulously designed to conform to JIS (Japan Industrial Standard) specifications, offering reliable performance and superior build quality. Perfect for industries requiring compact and efficient pneumatic solutions, this series combines precision engineering with enhanced durability.

The piston seal adopts a heterogeneous two-way seal structure, ensuring a tight dimension with exceptional grease retention for long-lasting operation. The aluminum profile cylinder barrel features hard anodizing treatment, delivering superior corrosion resistance and durability.

Compared to ISO15552 standard cylinders, the JSI Series offers a more compact design with a shorter cylinder length for the same diameter, making it ideal for space-sensitive applications. Its smooth and steady buffer adjustment ensures reliable performance under various operating conditions.

With a range of mounting accessories and specifications available, the JSI Series provides flexibility and ease of installation for diverse industrial needs.

Key Features:

Specification:

| Bore Size(mm) | 32 | 40 | 50 | 63 | 80 | 100 | 125 | |

| Acting type | Double Acting | |||||||

| Fluid | Air (Ensure optimal Air quality with a 40μm filter element) | |||||||

| Mounting Type | JSI | Basic FA FB CA CB CR LB TC TCM1 TCM2 | ||||||

| JSID, JSIJ | Basic FA LB TC TCM1 TCM2 | |||||||

| Operating pressure | 0.15~1.0MPa (22~145psi)(1.5~10.0bar) | |||||||

| Proof Pressure | 1.5MPa(215psi)(15bar) | |||||||

| Temperature °C | -20~70 | |||||||

| Speed range mm/s | 30~800 | 30~500 | ||||||

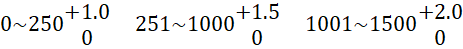

| Stroke tolerance |  |

|||||||

| Cushion Type | Variable Cushion | |||||||

| Adjustable cushion stroke | 20 | 20.5 | 29 | 33 | ||||

| Port Size [Note 1] | 1/8" | 1/4" | 3/8" | 1/2" | ||||

Stroke:

| Bore Size (mm) | Standard Stroke (mm) | Max STD Stroke | Max Stroke |

| 32 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 | 1000 | 1800 |

| 40 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 1800 |

| 50 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1200 | 1800 |

| 63 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 1800 |

| 80 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 1800 |

| 100 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 1800 |

| 125 | 25 50 75 80 100 125 150 160 175 200 250 300 350 400 450 500 600 700 800 900 1000 | 1500 | 1800 |

.png)

.png)

Malaysia

Malaysia