The AirTac MA Series Mini Round Cylinder is a high-performance pneumatic cylinder designed for compact applications requiring durability, precision, and reliability. Manufactured to the highest industry standards, this cylinder features a heterogeneous two-way piston seal structure that ensures a tight, efficient seal while maintaining grease reservation for smooth operation and extended lifespan.

Engineered for shock absorption, the front cover includes a fixed bumper, effectively reducing impact during direction changes. The front and back covers, along with the stainless steel block, adopt a riveted rolling packed structure, forming a solid and reliable connection for enhanced performance and longevity.

The high-precision stainless steel cylinder body offers exceptional strength and corrosion resistance, making it ideal for use in harsh industrial environments. Additionally, multiple back cover options allow for easy and flexible installation, while various mounting accessories provide adaptability for diverse applications.

One of the standout features of the MA Series is its built-in magnet, which allows for seamless integration with sensor systems to enable precise position detection and automation capabilities.

Key Features:

Specification:

| Bore Size(mm) | 16 | 20 | 25 | 32 | 40 | 50 | 63 | |

| Acting type | MSA/MTA | Single acting | - | |||||

| MA/MAD/MAJ | Double acting | - | ||||||

| MAR | - | Double acting | ||||||

| MAC/MACD/MACJ | Double Acting with cushion | |||||||

| Fluid | Air (Ensure optimal Air quality with a 40μm filter element) | |||||||

| Operating pressure | Double acting | 0.15~1.0MPa (22~145psi)(1.5~10.0bar) | ||||||

| Single acting | 0.2~1.0MPa (28~145psi)(2.0~10.0bar) | |||||||

| Proof pressure | 1.5MPa(215psi)(15bar) | |||||||

| Temperature °C | -20~70 | |||||||

| Speed range mm/s | Double acting: 30~800 Single Acting: 50~800 | |||||||

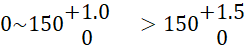

| Stroke tolerance |  |

|||||||

| Cushion Type | MAC/MACD/MACJ Series: Variable cushion; Other Series: Bumper | |||||||

| Port Size | M5x0.8 | 1/8" | 1/4" | |||||

Stroke:

| Bore Size (mm) | Standard Stroke (mm) | Max STD Stroke | Max Stroke | |

| MA\MAC | 16 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | 800 |

| MA | 20 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | 800 |

| MAC | 25 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | 800 |

| MAR | 32 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | 800 |

| MAC | 40 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | 800 |

| MAR | 63 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | 800 |

| MAD | 16 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 | 300 | - |

| MAJ | 20 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 | 300 | - |

| MACD | 25 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 | 300 | - |

| MACJ | 32 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | - |

| 40 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | - | |

| MACD | 50 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | - |

| MACJ | 63 | 10 15 20 25 30 40 50 60 75 80 100 125 150 175 200 250 300 350 400 450 500 | 500 | - |

| MSA | 16 | 10 15 20 25 30 40 50 60 75 80 100 | - | - |

| 20 | 10 15 20 25 30 40 50 60 75 80 100 125 150 | - | - | |

| 25 | 10 15 20 25 30 40 50 60 75 80 100 125 150 | - | - | |

| 32 | 10 15 20 25 30 40 50 60 75 80 100 125 150 | - | - | |

| 40 | 10 15 20 25 30 40 50 60 75 80 100 125 150 | - | - | |

| MTA | 16 | 10 15 20 25 30 40 50 60 75 80 100 | - | - |

| 20 | 10 15 20 25 30 40 50 60 75 80 100 | - | - | |

| 25 | 10 15 20 25 30 40 50 60 75 80 100 | - | - | |

| 32 | 10 15 20 25 30 40 50 60 75 80 100 | - | - | |

| 40 | 10 15 20 25 30 40 50 60 75 80 100 | - | - | |

.png)

.png)

Malaysia

Malaysia