The AirTac ACE Series Compact Cylinder is engineered in full compliance with the ISO21287 standard, offering vogue mounting dimensions and a space-saving design that makes it ideal for modern pneumatic systems. Compared to ISO15552 standard cylinders, the ACE Series can reduce installation space by up to 50%, making it the perfect solution for tight or high-density machinery layouts.

This compact cylinder features a high-strength construction, with the cylinder body and covers securely connected via threaded assembly for robust performance and easy maintenance. The internal bore is precisely rolled and hard anodized, delivering excellent abrasion resistance and extended service life.

The piston seal adopts a heterogeneous two-way sealing structure, enabling a compact form factor with oil retention capability for smoother, longer-lasting operation. The integrated magnetic switch slots allow for the quick installation of inductive switches, enhancing automation and positional control without the need for external brackets.

Additionally, a built-in bumper is available to absorb excess energy, minimizing vibration and impact. The ACE Series also supports a variety of mounting accessories, making it flexible and easy to integrate into a wide range of pneumatic systems.

Key Features:

Specification:

| Bore Size(mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 | 125 | ||

| Acting type | Single Acting_Push type, Single acting_Pull type | ||||||||||||

| Fluid | Air (Ensure optimal Air quality with a 40μm filter element) | ||||||||||||

| Operating pressure | Double acting | 0.15~1.0MPa (22~145psi) | |||||||||||

| Single acting | 0.2~1.0MPa (28~145psi) | ||||||||||||

| Proof pressure | 1.5MPa(215psi) | ||||||||||||

| Temperature °C | -20~70 | ||||||||||||

| Speed range mm/s | Double acting: 30~500 Single Acting: 50~500 | ||||||||||||

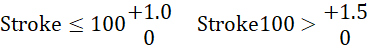

| Stroke tolerance |  |

||||||||||||

| Cushion Type | Bumper | ||||||||||||

| Port Size [Note 1] | M5x0.8 | 1/8" | |||||||||||

Stroke:

| Bore Size (mm) | Standard Stroke (mm) | Max Stroke | ||

| Common Type | Double Acting | 12 | 5 10 15 20 25 30 35 40 45 50 | 50 |

| 16 | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 | 75 | ||

| 20 | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 90 100 | 100 | ||

| 25 | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 90 100 110 120 125 150 | 150 | ||

| 32 40 | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 90 100 110 120 125 150 160 175 200 | 200 | ||

| 50 63 | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 90 100 110 120 125 150 160 175 200 225 250 | 250 | ||

| 80 100 125 | 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 90 100 110 120 125 150 160 175 200 225 250275 300 | 300 | ||

| Single Acting | 12 | 5 10 | 10 | |

| 16~100 | 5 10 15 20 25 | 25 | ||

| Non Rotating with Yoke | Double Acting | 12 | 5 10 15 20 25 30 35 40 45 50 | 50 |

| 16 | 5 10 15 20 25 30 35 40 45 50 55 60 70 75 | 75 | ||

| 20 25 | 5 10 15 20 25 30 35 40 45 50 55 60 70 75 80 90 100 | 100 | ||

| 32 40 | 5 10 15 20 25 30 35 40 45 50 55 60 70 75 80 90 100 | 100 | ||

| 50 63 | 5 10 15 20 25 30 35 40 45 50 55 60 70 75 80 90 100 | 100 | ||

| 80 100 | 5 10 15 20 25 30 35 40 45 50 55 60 70 75 80 90 100 | 100 | ||

.png)

.png)

Malaysia

Malaysia