1D code identification with easy to integrate IO-Link or dual port scanner

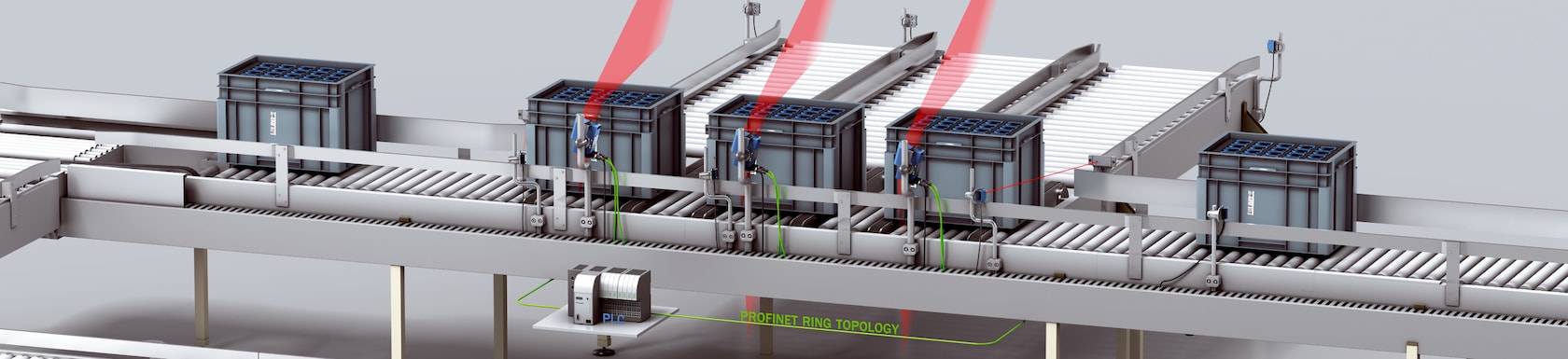

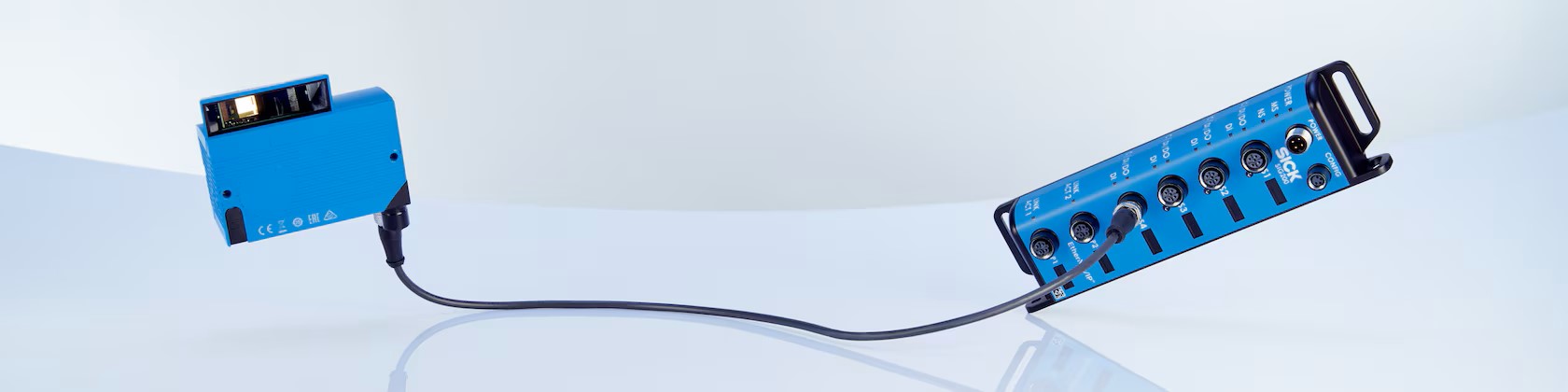

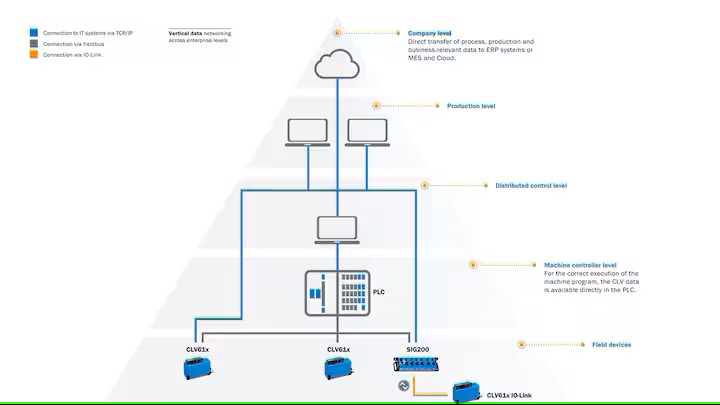

The CLV61x fixed mount barcode scanner impresses with its compact design and can be easily integrated even where space is tight. The versatile communication interfaces enable use of scanners in countless applications. For example, the integrated CAN bus networks several fixed mount barcode scanners into one system. In intralogistics, the CLV61x is always the right choice, either in the dual-port type with two integrated PROFINET connections or with corresponding connection technology such as the Connection Device Fieldbus fieldbus module or an IO-Link master. Different product variants ensure flexible connection to all common fieldbus and industrial Ethernet interfaces. This means the CLV61x can be configured directly from the control environment.

CLV61x AT A GLANCE

Benefits

-The right scanner variant of the CLV61x for each application

-An optimized reading field for container identification on a conveyor belt, in combination with the intuitive SOPAS user interface, enables quick and easy integration into your conveyor system

-Compact design enables installation even in applications with limited space

-Less programming time required for the control system, since data can be transmitted to the control system in the desired format

-Depending on the variant, CLV61x fixed mount barcode scanners can be used as multiplexers in any SICK CAN sensor network, so additional multiplexers are not required

-The optional configuration cloning module in combination with the quick-release mounting bracket enables very fast replacement time in the event of a fault

Features

-Reading field and rugged design ideal for intralogistics applications

-Flexible interface concept: CANopen, SICK CAN sensor network, serial, PROFIBUS DP, PROFINET, EtherCAT, IO-Link

-SICK CAN sensor network for networking multiple fixed mount barcode scanners or multiplexers/servers

-Connection option for trigger sensors in IO-Link devices

ADVANTAGES

Flexible and reliable

Flexible and reliable

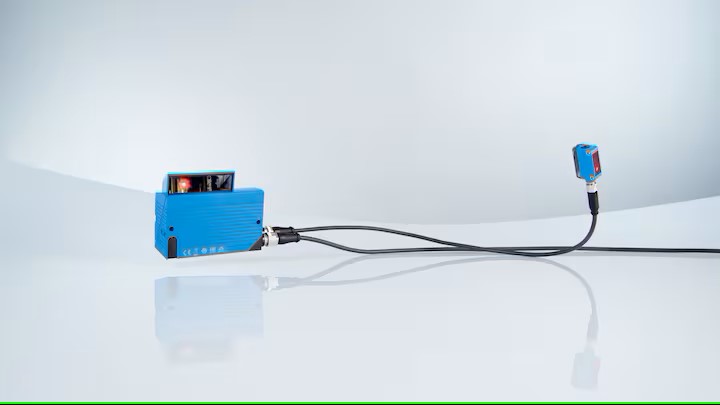

The strengths of the CLV61x are clear to see: A compact housing with flexible connection options to all common fieldbus and industrial Ethernet interfaces. This also facilitates the connection of sensors that trigger reading processes, such as photoelectric sensors.

.jpg)

Space is tight? No problem.

The smaller the installation space, the greater the challenge for the fixed mount barcode scanner. The compact device design of the CLV61x allows for easy installation even where space is tight.

Communication via tried and tested interfaces

The CLV61x covers all common interfaces and therefore offers a high degree of flexibility for integration into the control environment. Not only line but also ring topologies can be easily created without major cabling effort. The latter operate redundantly and ensure high system availability. Depending on the variant, the CLV61x has integrated communication interfaces or external interfaces by means of a connection module.

Reliable performance even for difficult barcodes

With the SMART620 code reconstruction, even damaged, contaminated and partially obscured barcodes can be reliably read. Even codes that are twisted by up to 30° can be precisely detected.

Compact, flexible, and reliable: The CLV61x impresses with excellent reading performance and a large working range, even with tight installation spaces and short reading distances.

Sophisticated concepts for challenging reading conditions

Sophisticated concepts for challenging reading conditions

The demands on machine design are increasing in intralogistics. Tight space, difficult access to the installed devices or large fluctuations in temperature – the CLV61x provides solutions to all of these challenges.

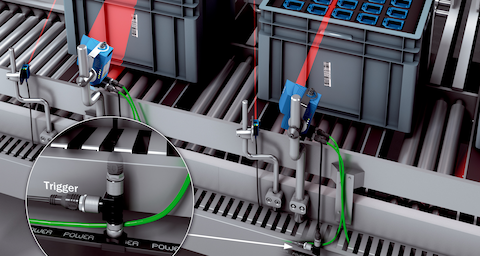

Without additional cabling: The power and trigger concept (ASi PWR)

The CLV61x with dual port can use existing ASi cables for the voltage supply. This reduces the cabling effort enormously. Since no external connection module is required, this concept saves time as well as costs for acquisition and operation.

Withstands fluctuating ambient temperatures

Depending on the device variant, the CLV61x is equipped with integrated heating in order to work reliably even in deep-freeze environments down to –35 °C. The fixed mount barcode scanner requires neither additional installation space nor extra cabling to connect the heating.

Swivel connector for simple handling

The swivel connector of the CLV61x with dual port enables flexible alignment of the sensor, thus facilitating mounting and integration into a network even under very difficult installation conditions.

Flexible and intelligent solutions in response to increasing requirements in intralogistics

IO-Link

IO-Link

SICK is a co-founder of IO-Link and offers a very broad range of IO-Link products. Together with many other sensors and actuators, identification solutions from SICK use IO-Link interfaces to generate and receive data and information that go beyond conventional switching signals or measured process parameters. Here you will learn how you can use different sensors combined with the IO-Link Master.

Your advantages at a glance

Increases system productivity

Integration of the sensors at the fieldbus level enables continuous communication up to the cloud. It also allows sensor data to be stored centrally and called up as needed, which is a good basis for increasing system productivity.

Fast commissioning by means of an integrated trigger

The direct connection of a trigger sensor enables quick and easy commissioning.

Quick and easy device replacement

Easy device exchange due to automated device identification: When using IO-Link devices in connection with the IO-Link Master, device parameters can be transmitted to replacement devices quickly and easily. Specially trained staff, additional tools or instructions are not required.

Wide range of solutions

The range of solutions from SICK includes many different devices with IO-Link. This enables a uniform communication infrastructure. In addition to the sensors, IO-Link Masters and other software from SICK also play a key role.

With point-to-point communication protocols, IO-Link ensures seamless sensor integration into automation networks. This creates the basis for data transparency down to the lowest field level. This opens up new approaches for digitalization. The data obtained helps to increase flexibility, reliability and efficiency and makes it possible to reduce costs in your plant.

Virtual product demo before purchase? SICK makes it possible.

Virtual product demo before purchase? SICK makes it possible.

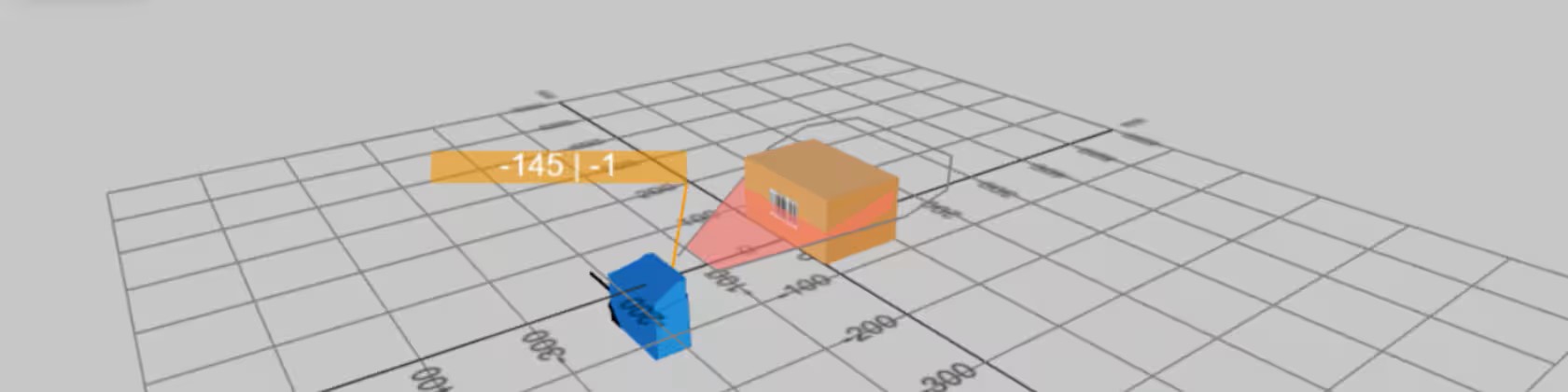

Bring our products to life: Our reading field visualization tools can be used to visualize all CLV61x device variants. Select your device parameters and use our tool to find out which product variant is the best one for your device. Uncertainty when selecting products is a thing of the past.

Use product visualization to help you select the exact right product before you buy.

SICK LifeTime Services

SICK’s services increase machine and plant productivity, enhance the safety of people all over the world, provide a solid foundation for a sustainable business operation, and protect investment goods. In addition to its usual consulting services, SICK provides direct on-site support during the conceptual design and commissioning phases as well as during operation.

The range of services not only covers aspects like maintenance and inspection, but also includes performance checks as well as upgrades and retrofits. Modular or customized service contracts extend the service life of plants and therefore increase their availability. If faults occur or limit values are exceeded, these are detected at all times by the corresponding sensors and systems.

.jpg)

Consulting and design

Application-specific advice on the product, its integration and the application itself.

.jpg)

Commissioning and maintenance

Application-optimized and sustainable ─ thanks to professional commissioning and maintenance by a trained SICK service technician.

.jpg)

Service contracts

Extended warranty, SICK Remote Service, 24-hour helpdesk, maintenance, availability guarantees and other modular components can be individually combined on request.

Malaysia

Malaysia