High-speed continuous printing of 136 ppm*1 has been realised for both 1-sided and 2-sided printing.

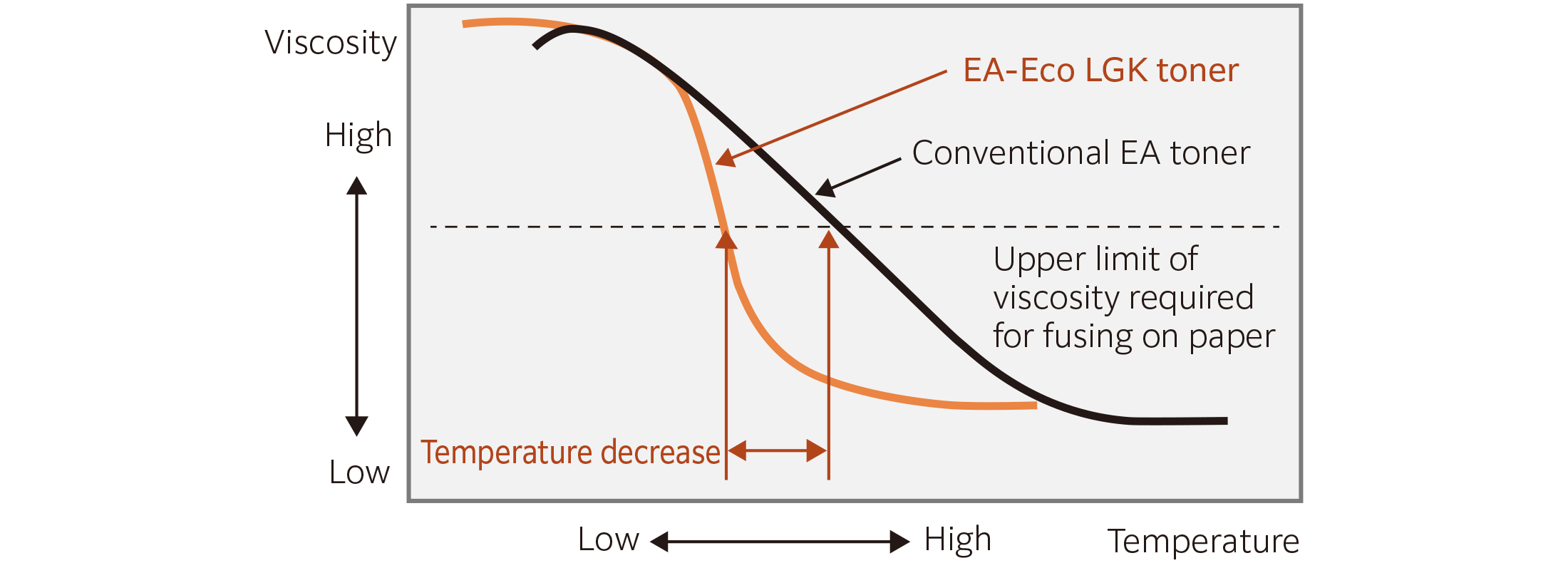

Reliable fusing on paper transported in high-speed is now possible with EA-Eco LGK*2 toner that allows fusing at lower temperature than existing models and a roll type fusing unit providing constant heat supply.

You can enjoy seamless operation at continuous mass printing as cartridge replacement and paper refill can be done while printing is in progress. A single high capacity toner cartridge can yield approximately 71,500 pages* for printing.

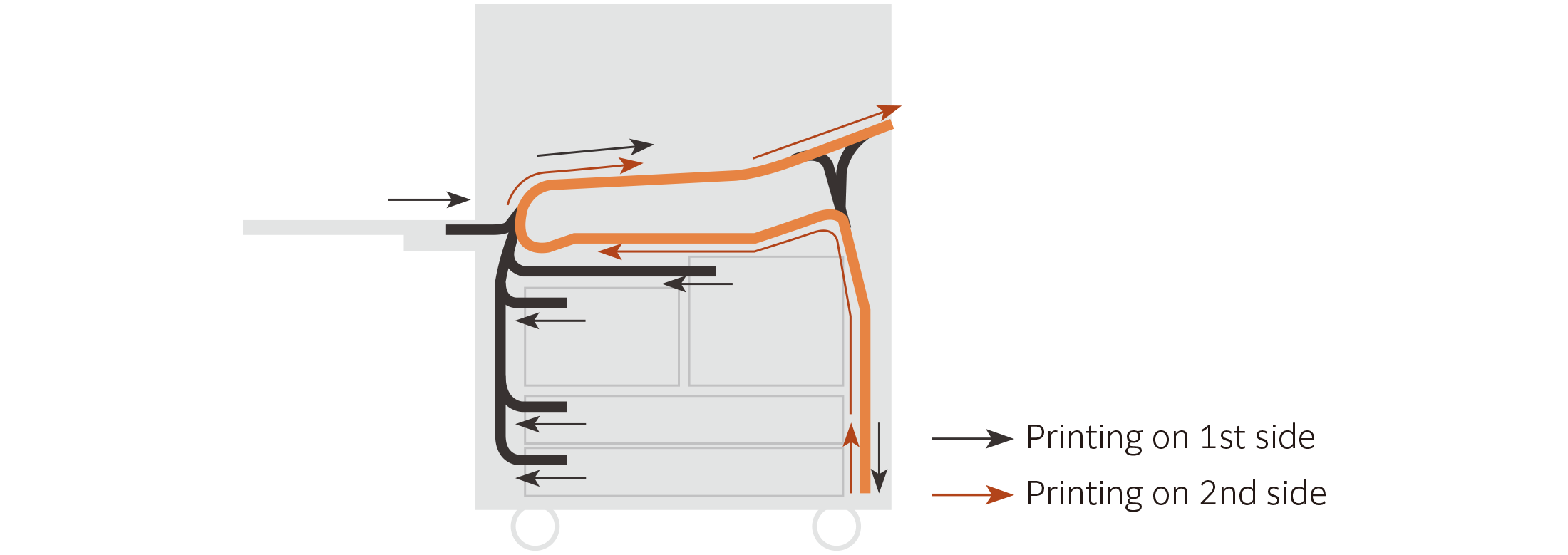

Wide turning angles in paper path provide stable and speedy paper transport. This device has a good resistance against paper jam by adopting vertical paper inversion mechanism for 2 sided printing to reduce curves in the paper path.

In addition, there is less impact caused by heat generated by fused paper on the transfer mechanism and it hardly causes troubles with paper path and image quality.

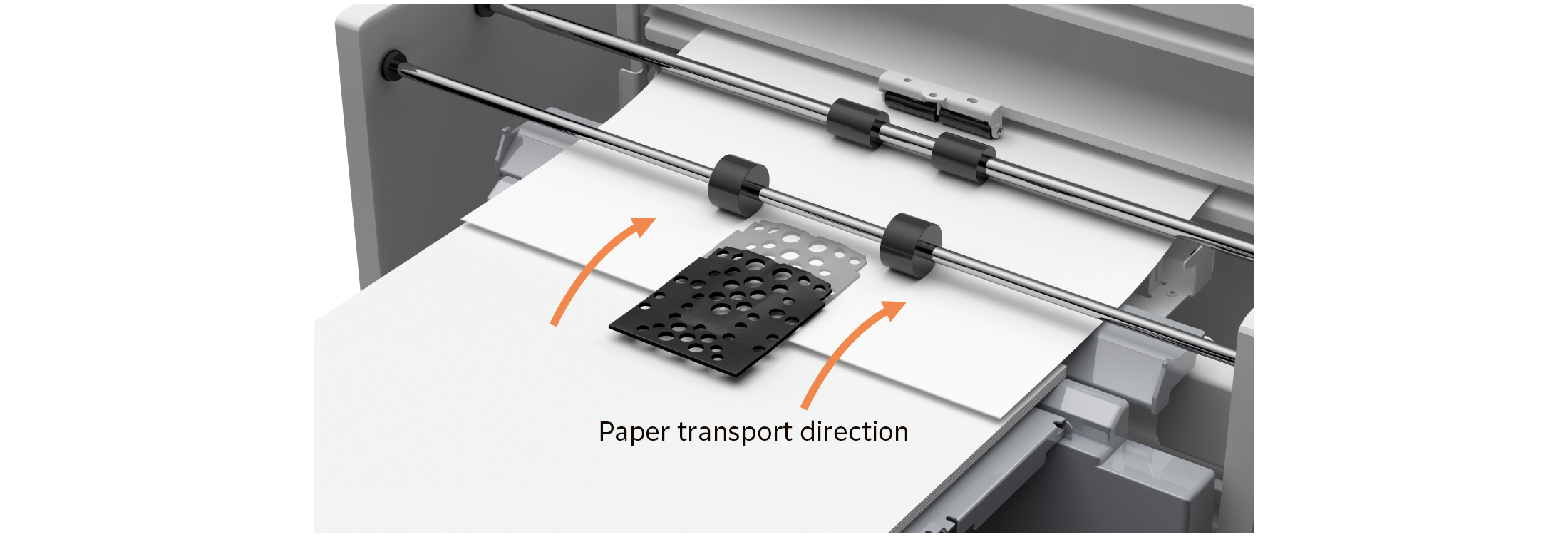

Newly developed Air Suction Feeder. Shuttle head draws up the paper strongly using a small amount of air, it easily separates and delivers each sheet efficiently. This even improves feed performance of paper with a lot of paper dust, pre-printed paper using powder, paper with uneven texture, and coated paper that is prone to sticking. Stable and high-speed feed is achieved for various paper types, from lightweight to heavyweight, small-sized paper and long paper.

The heart of the printer, ROS*1, uses VCSEL*2 as a light source.

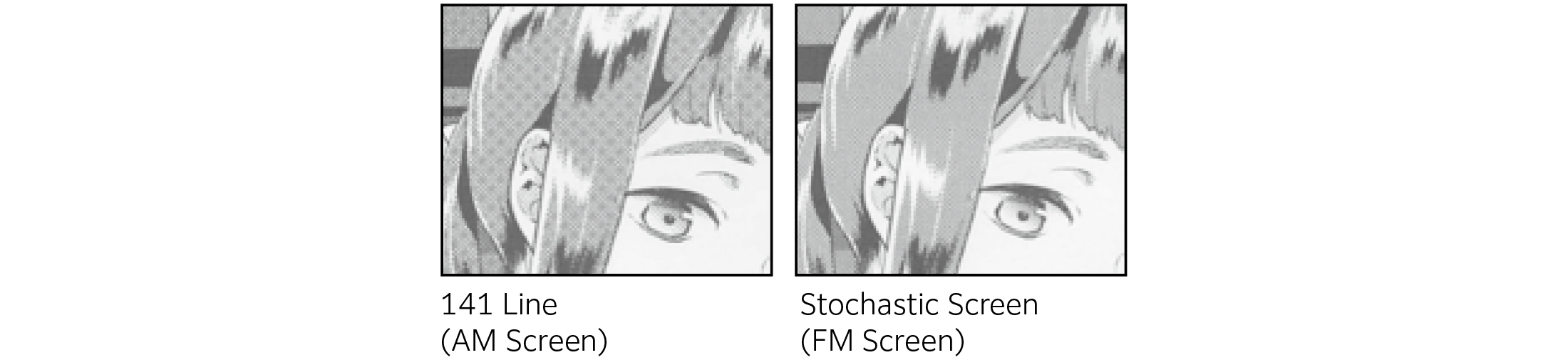

It enables printing at 2,400 x 2,400 dpi high resolution by drawing images simultaneously with 32 laser beams.

EA-Eco LGK toner with extremely small particle size of 6.5 microns allows reproduction of photograph gradation in a smooth and beautiful way, density uniformity in figures, and small text clearly. It also produces easy-to-read printed text with less glare which is also easy on your eyes.

Designed to prevent fluctuations in paper transport speed even in a compact body. Stabilize driving speed of the transfer belt by increasing the roll diameter. Automatic adjustment of contact pressure between transfer belt and drum. It ensures consistent transfer even on thin or thick paper.

This digital image registration control technology ''IReCT*'' precisely measures the position of sheets running in high-speed and realises real time correction to misregistration of printing images and distortion on each sheet with ultra high precision registration, which cannot be achieved by mechanical correction technology alone.

Simple Image Quality Adjustment (SIQA), which realises simple alignment adjustments has been installed. For optimal adjustment, you can just print and scan the calibration chart. It ensures consistent printing quality with properly adjusted print position, perpendicularity, skew and magnification on both the front and back sides.

Various screen settings*1 including FM screen that suppresses moire*2 are available.

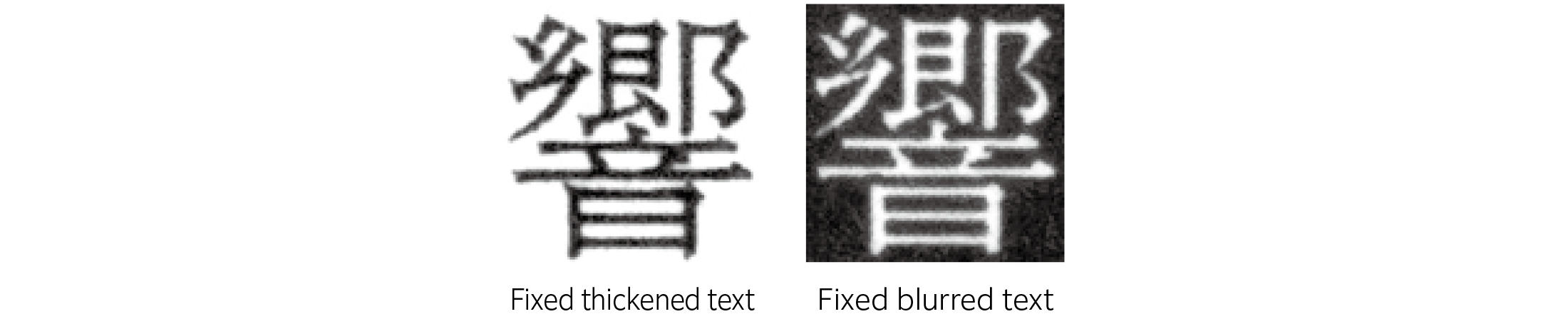

Higher image quality has been implemented with ''Edge Enhancement'' that fixes jaggedness on the edge of thin line and text outline and ''Adjust Invert Text/Line Weight'' that fixes thickened/blurred text.

Adjust Invert Text/Line Weight is ON (8 pt character)

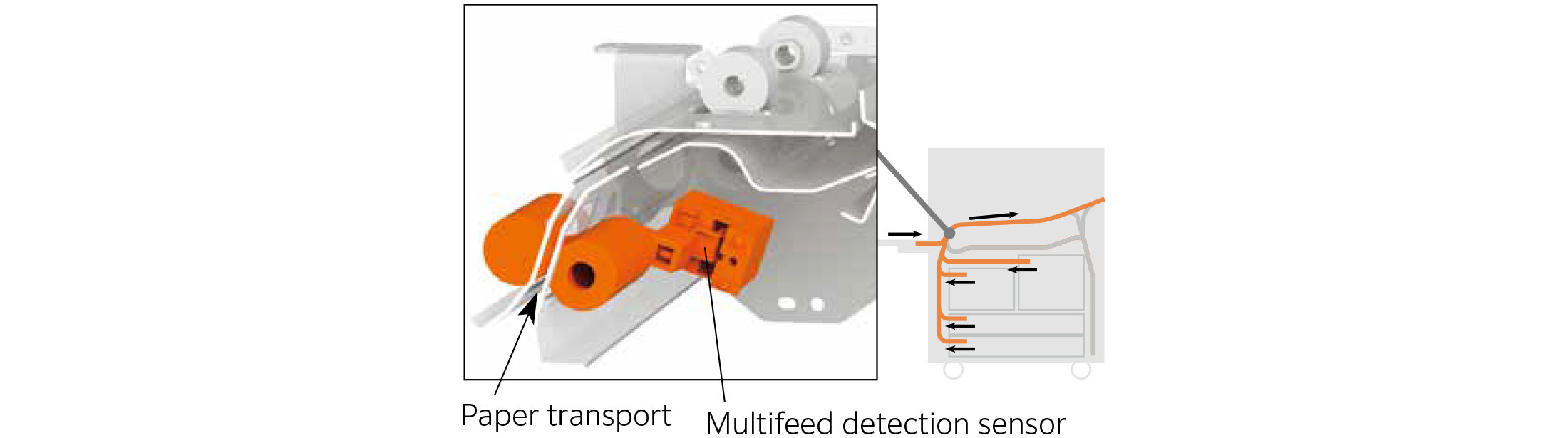

The multifeed detection sensor monitors the paper flow to prevent the feeding of multiple sheets of paper. If a multifeed is detected, printing is interrupted to prevent blank page insertion.

Monitors paper thickness

Monitors paper thickness

A wider range of media types and finishes.

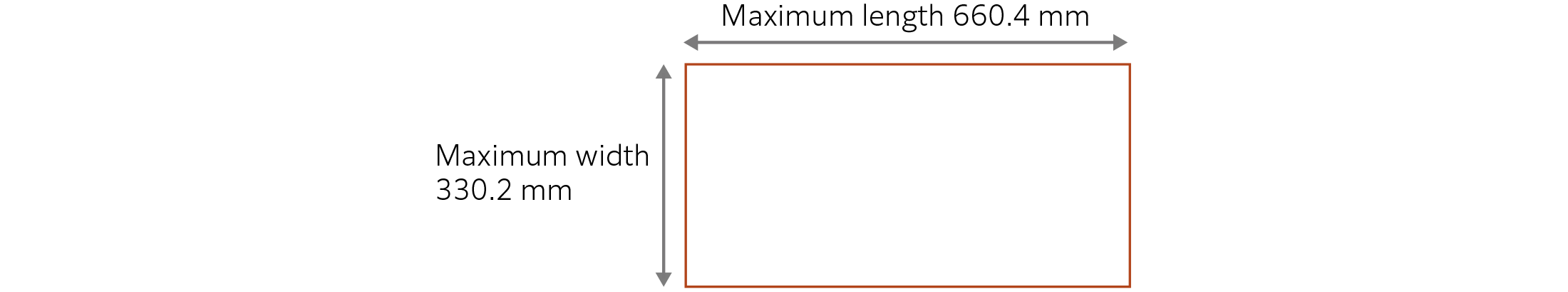

This device can handle a wide range of paper weights from lightweight paper of 52 gsm to heavyweight paper of 350 gsm. The upper limit of heavyweight paper has been extended thanks to the paper path design, and employing the control mechanism that automatically switches fusing roll pressure between two levels. Not only that, it allows fine control to extend the support range of coated paper and specialty paper*1. Paper sizes ranging from A6 to 330.2 x 488 mm are available. Full-bleed printing on SRA3 (320 x 450 mm) is also possible and it is useful to create brochures or leaflets that need to have bleed. Further, banner printing on long paper of up to 660.4 mm is now available.*2 New print applications will expand such as powerful panoramic posters.

A maximum of 100 paper types can be registered with ''Custom Paper Settings''. It allows configuration settings such as alignment, fold position, fusing temperature according to paper to be used and produce printout with high image quality.

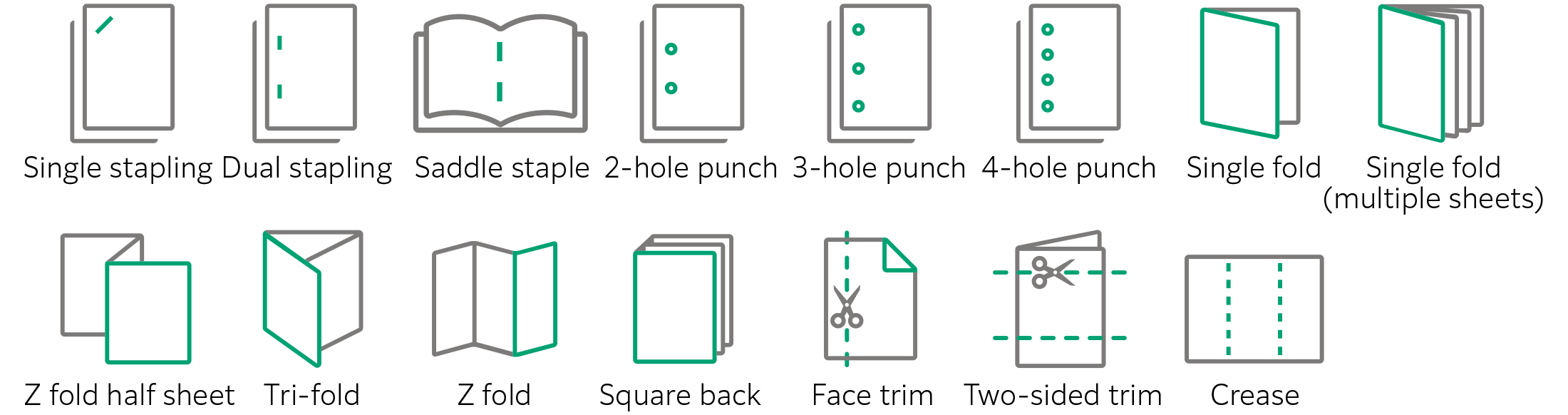

These options make it possible to build flexible printing systems suited to every printing operation.

Up to a total of 8,250 sheets can be loaded. You can enjoy long-time seamless operation at continuous mass printing with less paper refill frequency.

High Capacity Stacker A1 can accommodate up to 5,000 sheets. The printed sheets are directly delivered to the stacker cart (carriage). It is useful when carrying large volumes of printouts to off-line post-processing devices.

Print server with high resolution and fast processing.

The Print Server with 64-bit architecture delivers high speed RIP and high image quality, achieved through the latest hardware and image processing technologies cultivated in the development of colour production printers.

High quality image data can be generated with RIP processing of 600 x 600 dpi and 8 bit (256 gradation levels) on the Print Server.

In addition, high resolution and smooth screen image of 2,400 x 2,400 dpi can be generated on the device with our unique HQ digital screen technology (MACS*) employed. These data processing technologies have realised high image quality brought from the maximisation of the print engine performance.

Adobe® PDF Print Engine directly rips PDF data. Even a PDF file with transparency or layers can be processed as it is and faster and high quality output is possible.

Blur, drop shadow and glow effect can be used with ease.

Our unique intermediate data format streamlines RIP processing with high image quality. In the conventional RIP processing, calculation takes a long time due to large data volume. However, this new RIP processing automatically identifies objects including text and image and processes them in the format in which data volume is less. It greatly reduces the processing time without degrading image quality.

The print server sends huge raster data to the printer with a wideband transmission of 4.25 Gbps. It ensures high reliability by automatically detecting and correcting errors.

This feature allows you to print documents in an easy way when necessary as print information including paper type, 1-sided/2-sided, stapling is saved along with print data.

Xerox FreeFlow Makeready, software which streamlines prepress operations allows you to construct a digital printing system to handle both digital and paper document entries. This system makes it possible to use a wide range of editing functions such as imposition and labeling while checking page layout.

High-speed, large volume printing of personally customised documents: direct mails, bills, usage details statements, etc. is enabled. It meets the business needs of One to One marketing which captures diversifying customers' individual needs. With industry standard PPML*1, PDF/VT-1, and PDF/VT-2, languages for variable data printing and our unique language VIPP*2 are supported to establish extended variable printing systems.

JDF*1, which is the standard in the printing industry is supported. Linking with integrated workflow systems for printing operation*2, you can build a hybrid workflow with offset printing device and digital printer.

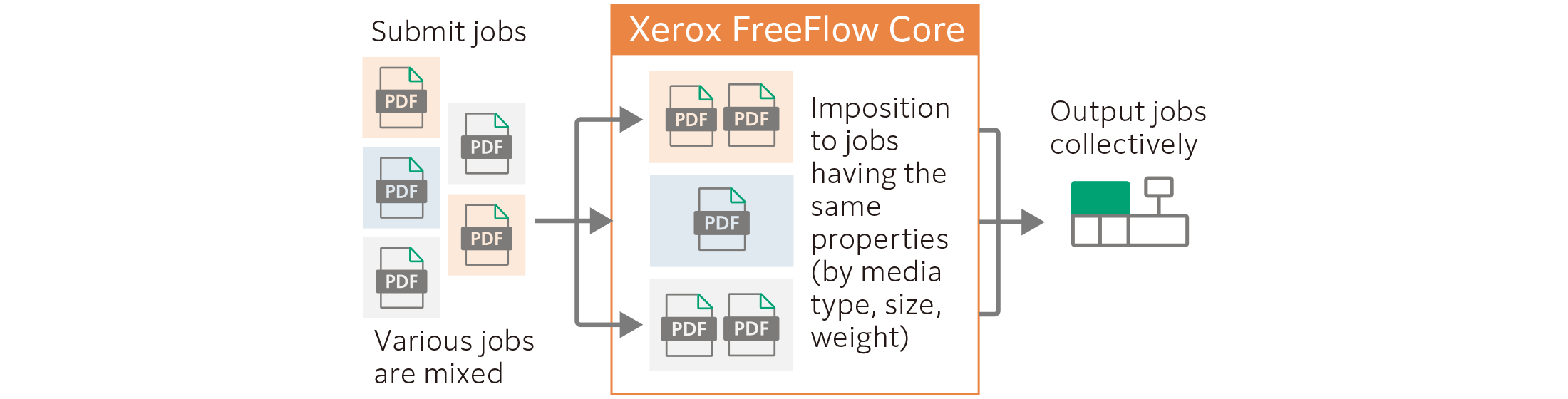

The efficiency of printing operation can be improved by grouping jobs having the same properties. It brings improved productivity and shorter turnaround with short-run printing of a wide variety of contents.

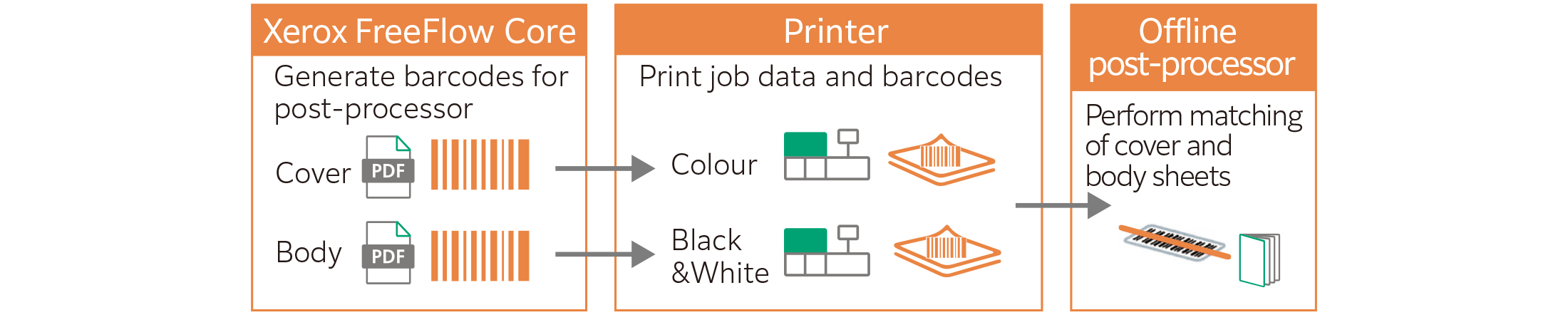

The efficiency of booklet making operation can be improved by using barcodes for post-processor.

It scans the front and back sides of the original simultaneously. Scan functions make it possible to read documents in high-speed of 136 ppm for 1 sided and 270 ppm* for 2 sided.

|

1 sided |

2 sided |

|

| Scan job* | 136 ppm (Colour/BW) | 270 ppm (Colour/BW) |

| Copy job | 100 ppm (BW) | |

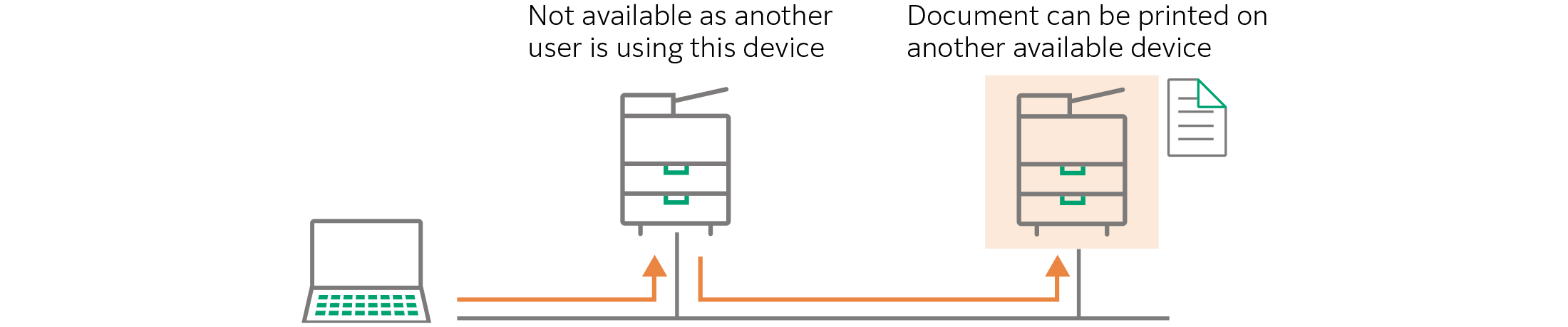

Even if the device you selected for output is occupied, you can print your documents from another available device on the network.

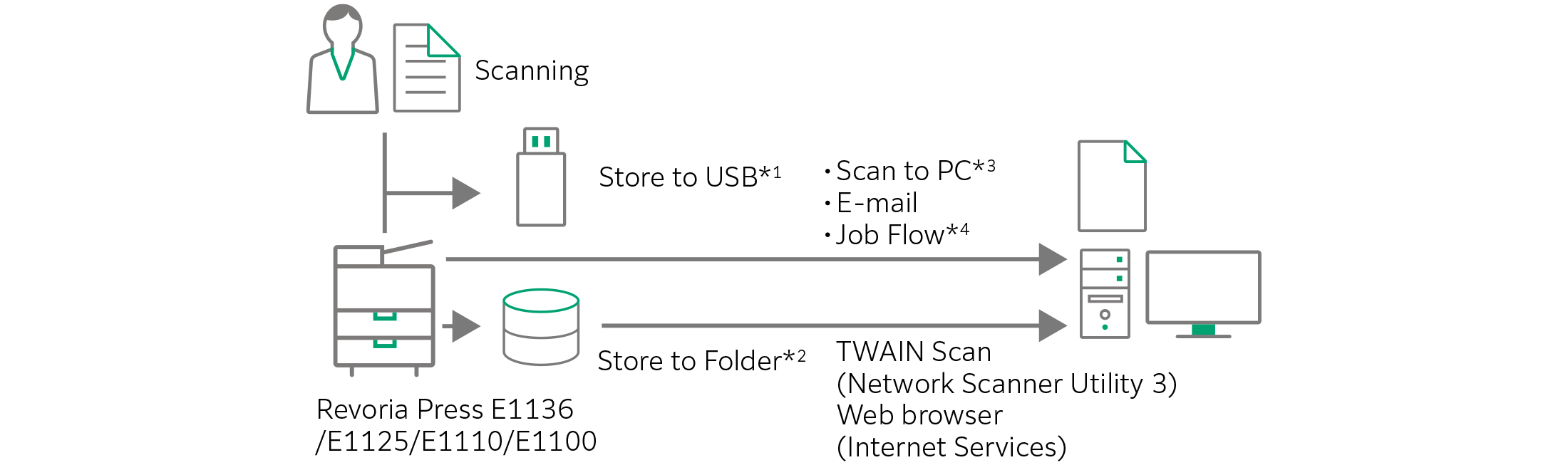

The following useful scan functions are available.

This feature stores copy documents in the [Folder for Reprint] Folder of the device. You can print them as many times as you wish without scanning documents each time. Besides edit operations such as duplication of document data, change of copy settings, document merge like insertion and re-saving are available.

Check-up and parts replacement can be performed at the perfect time by analysing the system log, and it prevents troubles.

If a problem occurs, our service engineer will remotely analyse the system log and provide technical supports to solve the problem in a short time period. In addition, FUJIFILM Business Innovation operator assists the troubled customer by sharing the print server screen remotely to solve the problem.

Important print data provided by customers can be protected from data breaches by securely erasing*1 deleted data remaining in the print server so that the data cannot be recovered even with data recovery software. Besides, data in the printer can be encrypted*1 or securely erased*2 to prevent unauthorised access.

Authentication features prevent unauthorised use of the device for security. Authentication operations can be performed at the device control panel or with a smart card*. User information can be saved and managed on the device or remote authentication server such as Active Directory.

When using authentication features without setting up an authentication server, it is troublesome and hard to manage with many devices as user information needs to be registered with each device. The ''Server-less Authentication'' feature allows authentication operations on any device as devices automatically synchronise user information.

更多 Mewamax Sdn Bhd 相关资料

Malaysia

Malaysia