Fully Integrated Pump Variable Frequency Pump BLE

Overview Of The ProductFully integrated intelligent variable frequency pump was developed by the company's latest frequency conversion controller and the water pump, pressure tank and so on a new generation of highly integrated pressurized water supply equipment, aesthetically pleasing, has reached the international advanced level, with artificial intelligence, can automatically adjust the constant pressure frequency conversion water supply in order to meet user requirements, keep the water supply pipe network pressure constant, and the whole system always maintain the best condition of high efficiency and energy saving.

◎ Residential water:High-rise building roof pressurization, apartment, villa and so on.

◎ Public places: schools, restaurants, stations, hospitals, gymnasiums, etc.

◎ Commercial buildings: hotels, office buildings, department stores, etc.

◎ Irrigation: farms, orchards, parks, etc.

◎ Industry: manufacturing, food manufacturing, industrial water and other constant pressure water supply sites.

◎ Working voltage: AC220V ± 10%, 50Hz, and less than 2%.

◎ Ambient temperature: - 5 ℃ to 40 ℃

◎ Installation site elevation no more than 1000m.

◎ Environmental humidity 10~90%RH (non-condensing)

◎ There is no explosive dangerous medium in the surrounding air, and there is no gas or conductive dust in the medium that corrodes the metal and damages the insulation, and is used in the pollution level 2 environment.

◎ When using water, system constant voltage frequency control, automatic pressure stop when water is not used.

◎ The operating pressure fluctuation range of frequency conversion pump is not greater than 0.01MPa.

◎ No water, the pump stop

◎ It has several fault detection functions such as broken line, overcurrent, overload and grounding.

◎ Inverter: IP65 protection grade, safe and reliable.

◎ High integration: water pump and frequency converter integrated, small volume, easy to install, save space.

◎ Fully automatic control: the system can be adjusted automatically according to the user's pipe network pressure to achieve the optimal running state and make the system more energy efficient. Automatic pressure protection, dormancy and energy saving effect are obvious when no water is used. When pump failure, automatic real-time tracking judgment and processing.

◎ Easy to operate, simple, can be directly through the buttons and display on frequency converter, realize the human-computer interaction function, the user can according to own actual stress related Settings, running state and obtain relevant information, when abnormal, can obtain abnormal information.

◎ Constant power operation: when the controller to limit the power and will be adjusted according to the actual operation situation, under the condition of the water as much as possible, to ensure the user, the output power is constant, for the protection of the motor.

◎ Automatic identification module through the pressure sensors' system, compare it with the set pressure value calculation, and output analog signal to frequency converter, frequency conversion controller according to the changes of the analog signal again change motor operating frequency, so as to achieve constant industry water supply demand. When the permanent user USES large amount of water, automatically increases the speed and increases the power to meet the constant pressure water supply demand. When there is no water, after the system reaches pre-set pressure automatic dormancy, when a user a small amount of water or pipeline leaking caused the water pressure drops to 80%, the frequency conversion controller back signal, command the motor running, the pressure compensation to the set pressure, maximum achieve energy saving.

◎ Installation in the indoor, no leakage, no metal dust, no oil dust, no corrosive flammable gas or liquid, no electromagnetic signal interference. When installed outside, there should be a screening device.

◎ The installation ground of frequency conversion pump must be firm, there can not be subsidence or cracking phenomenon.

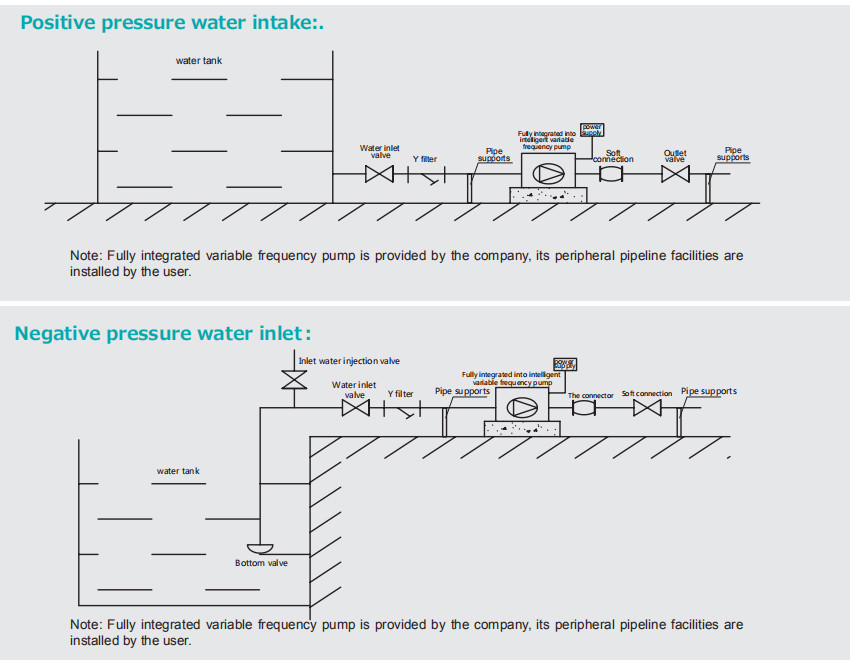

◎ When the equipment is installed, adopt imported positive pressure installation, try not to adopt negative pressure suction installation. If negative pressure installation is necessary, please select a good quality valve and check regularly.

◎ The inlet pipe and outlet pipe of the variable frequency pump must be greater than or equal to the variable frequency pump's own pipe diameter.

◎ Pay attention to whether the supplied power supply conforms to the input power requirements of the frequency conversion pump.

◎ At the time of installation, please provide the import and export valve of the frequency conversion pump and the soft connector which is connected to facilitate the maintenance and prevention of noise passing through the pipeline.

◎ After installation of imported positive pressure, please open the vent valve of the pump before using, and then release the gas until the water is tight. The suction pipe is filled with water (the water suction pipe should be equipped with water filling valve) before use, and the pump chamber is filled with water.

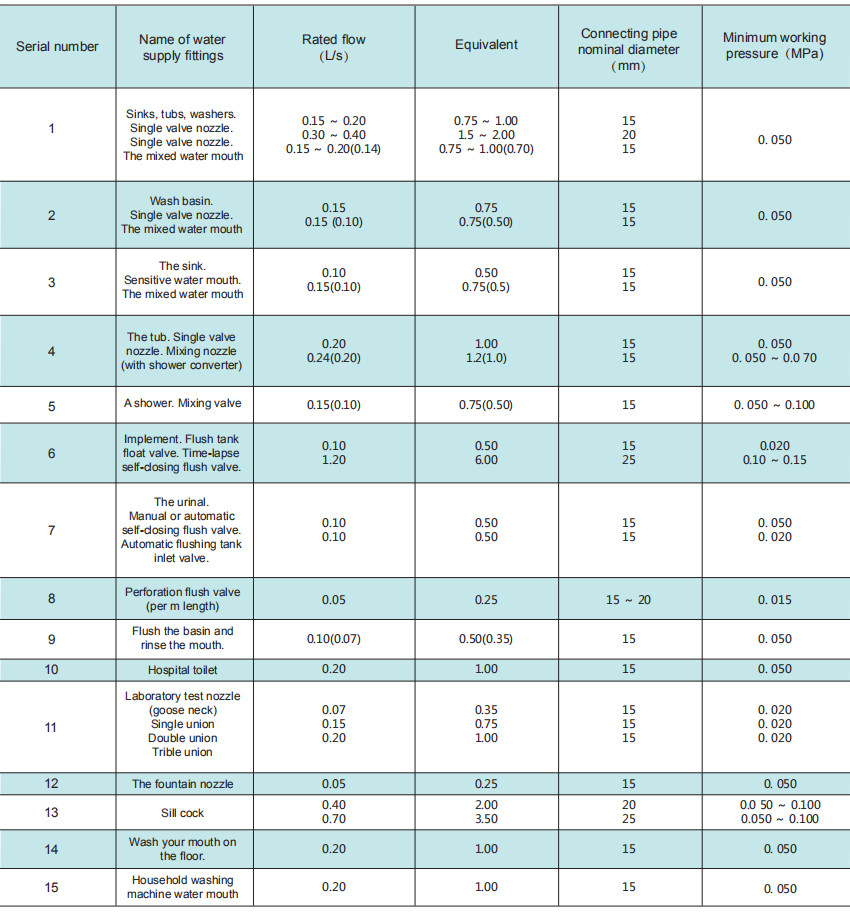

Calculation method for maximum water consumption (table 1)

◎ The numerical values in the brackets are used when water is supplied, when cold or hot water calculated separately.

◎ When the tub is attached with a shower or mixed nozzle with a shower switch, its rated flow and equivalent amount of water nozzle, regardless of the shower, but water pressure according to the shower meter.

◎ Domestic gas water heater, the water pressure required by the product requirements and hot water supply system is the most unfavorable distribution point required work pressure determination.

◎ The automatic sprinkling irrigation of green space should be according to the product design requirements.

◎ When the rated flow and minimum working pressure required for the plumbing fittings are specified, the value shall be determined according to the product requirements. (how to determine the yield when the product is determined)

◎ Maximum water consumption.

◎ L= single-valve nozzle number * rated flow + mixed nozzle * rated flow +... + number of household washing machines * rated flow rate.

◎ The calculated L unit is (L/S) converted to tons/hour with the coefficient of 3.6 (the rated flow is shown in table 1)

Malaysia

Malaysia