Thin and compact incremental encoder for economical solutions

The DLS40 incremental encoder is a reliable solution for measuring rotation speed and position. With various unique features, it is fundamentally redefining the operating principle of encoders. The housing integrated in the flange enables a low-cost, slim and compact design and therefore uncomplicated installation, especially in tight spaces. The DLS40 offers solid shafts and blind hollow shafts with a variety of mechanical and electrical interfaces. In addition, the encoder is equipped with an easily-accessible laser-marked QR code which enables direct access to the operating instructions.

DLS40 AT A GLANCE

Benefits

-The compact design facilitates the integration of the encoder even where installation space is limited and helps reduce machine size

-The flange with integrated housing enables a very compact and cost-efficient design

-A wide variety of output signal options makes it easy to find the right solution for every application\

Features

-Pulses per revolution: Up to 1,024

-Housing diameter: 40 mm

-Solid shaft and blind hollow shaft

-Enclosure rating: IP50 (Solid shaft)

-Communication interfaces: TTL/RS-422, HTL/Push Pull, Open Collector

-Connection type: cable

-Slim, compact design

ADVANTAGES

Even with tight installation space, the DLS40 incremental encoder can be easily integrated into machines. In addition to its slim housing with integrated flange, the blind hollow shaft also saves space. The universal stator coupling ensures great flexibility in the installation position. This enables particularly compact machine designs in the development of new machine.

Even with tight installation space, the DLS40 incremental encoder can be easily integrated into machines. In addition to its slim housing with integrated flange, the blind hollow shaft also saves space. The universal stator coupling ensures great flexibility in the installation position. This enables particularly compact machine designs in the development of new machine.

Very compact: With solid shaft only 20 mm, with blind hollow shaft 25 mm

The encoder is available with a 6 mm solid shaft or hollow shafts with a diameter of 6, 8, 10 or 12 mm

The universal stator coupling can be mounted at various points on the machine and thus adapted to it

The DLS40 can be integrated into numerous applications while saving space and enables particularly compact machine designs.

Versatile, powerful, universally applicable

Versatile, powerful, universally applicable

With up to 1,024 pulses per revolution, the DLS40 incremental encoder enables precise speed and position measurements at up to 6,000 revolutions per minute. When combined with various output signals and numerous hollow shaft diameters as well as a solid shaft variant, the encoder is suitable for many automation systems and applications.

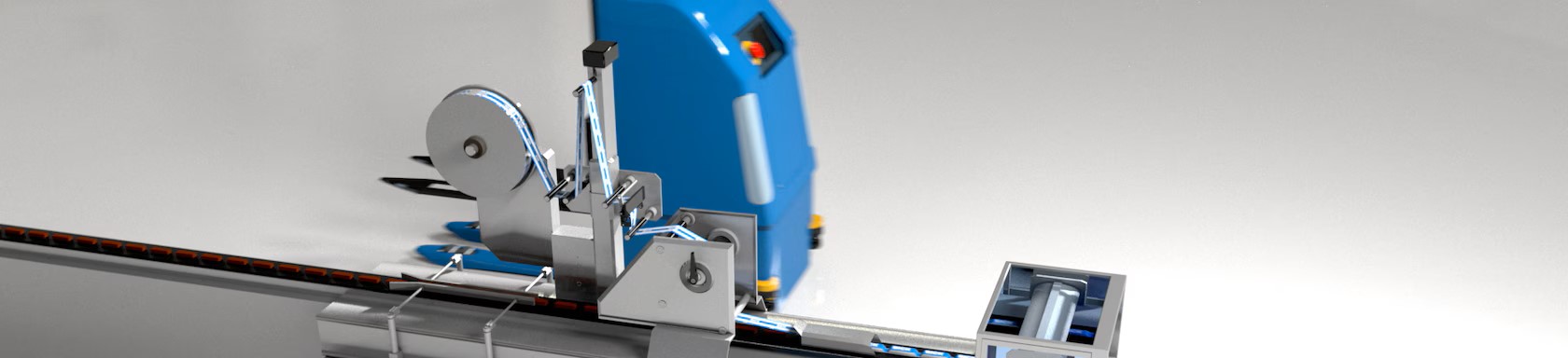

Packing machines

The DLS40 provides very accurate data for the positioning of packaging bags before they are cut

Automated guided vehicle (AGV)

The encoder delivers exact speed data from the drive unit to the vehicle controller – including information on the direction of travel

Many common output signals

Many common output signals:

4.5 V to 5.5 V, TTL RS 422; 10 V to 27 V, HTL Push Pull; 10 V to 27 V, Open Collector

The DLS40 offers particularly accurate speed and position data, and is well-suited to many applications thanks to its different output signals and performance parameters.

Resilient

Resilient

The DLS40 is compact and economical without doing away with essential features. Despite the slim housing, the permissible shaft loading of 40 N (radial) and 20 N (axial) provides the high resistance required for many applications. Special mechanically adjustable locking threads have been used to withstand the high shock and vibration loads of modern dynamic applications. These ensure that the screws do not loosen on their own. The housing also provides very good protection against electromagnetic interference, which means the DLS40 can be used in many demanding applications.

Easily withstands strong shaft loading up to 40 N radial and 20 N axial

Can withstand very different ambient conditions thanks to IP50 and a wide operating temperature range from –10 °C to +70 °C

Thanks to the electromagnetic compatibility of the encoder, electromagnetic fields do not affect measurement accuracy

The rugged design of the DLS40 ensures high reliability and makes it possible to use it under demanding ambient conditions.

Online access to product data

Online access to product data

The type label of the encoder was inscribed by laser engraving. The advantage: This protects it from wear. Current product information, technical data and operating instructions can be accessed online using a QR code. As no paper is used, this type of data access is also sustainable.

Permanently attached: The laser-engraved type label is durable, which means the encoder information is legible for a very long time. Thanks to cloud-based documentation, the information can be viewed anywhere and around the clock.

Malaysia

Malaysia