Description

ANTI SEIZE materials and compounds are used on threads, bolted joints and even ACME thread installation. The purpose of anti-seize is to prevent the bolt or screw threads from well seizing and convert torque to tightening force more efficient. Anti-seize improve the gasket performance, prevent thread from galling and seizure also protect thread from highly corrosive environment. This helps you from wasting lots of money and time to repair also save you from headache.

Type of Anti Seize

1) Copper Compound

Copper anti-seize can operate until 1100 Degree Celcius. Copper is the most favourable anti-seize as it has good corrosion protection. Copper can be applied on all steel except for stainless steel. Copper on stainless steel create an intracrystalline corrosion and cause the stainless steel to crack and break.

2) Nickel Compound

Nickel anti-seize has excellent chemical and oxidation resistance. This make this product suitable to be used in oil and gas industry. Nickel is a good anti-seize and provide superior corrosion protection on all steel include stainless steel. The maximum operation temperature of nickel anti-seize until 1400 Degree Celcius.

3) Chrome Compound

Chrome anti-seize has high operating temperature up until 1500 Degree Celcius. Chrome is the most superior anti-seize and can operate under extreme temperature and enviroment also give good corrosion protection.

Product Link:-

https://www.davor.com.my/index.php?ws=ourproducts&cid=196505&cat=Anti-Seize-Compound#openproducts

Typical Properties

| |

ANTI SEIZE |

| Consistency |

NLGI No. 2 |

| Penetration (1/10mm at 25°C, 60x) ASTM D217 |

275 |

| Penetration change (10 000 x) |

35 |

| Dropping point |

None |

| Timken OK load, kg (ASTM D2509) |

>25 |

| Copper corrosion test (ASTM D130) |

1b |

| Base oil viscosity at 40°C, cSt (Brookfield) |

100 |

Types of Seizing

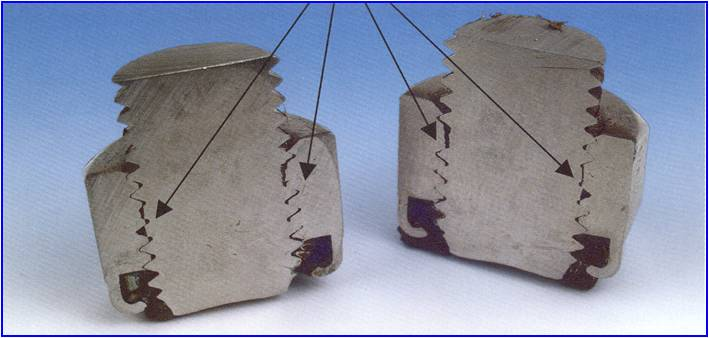

1) Galling - Cold welding cause the thread damaged

Galling is an adhesive wear that occurs when two metals are in contact and compressed against one another that built up pressure which cause friction. The friction produce heat that enough to weld the metals together. Galling is a potential problem in threaded assembling, for example fastening bolt and nut. This led to the breakage or torn of the thread resulting the bolt and nut to freeze and tighten.

Galling on the thread of bolt and nut

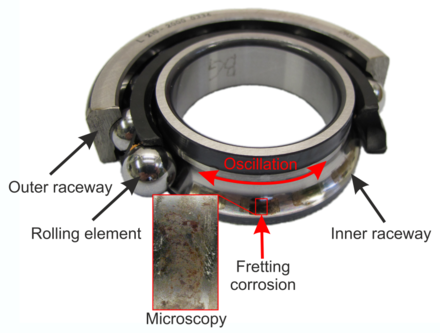

2) Fretting - Bolt fatigue after oxidation on friction area (due to oscillation)

Fretting wear or fretting corrosion caused when two metals in contact experiencing repeated relative motion by vibration (oscillation) and put under load. The contact movement cause rupture of the material and material transfer at the surface called debris. If fretting occurs in corrosive condition, oxidation on the wear surface will cause corrosion. In normal condition fretting caused the metals to fatigue crack and decrease the fatigue strength of the materials.

Mechanism of the fretting corrosion

Packing

500 gram can

400 ml aerosol can

Malaysia

Malaysia